Ultimate Guide to Medium Voltage Switchgear in Automation

Share

Medium voltage switchgear, operating between 1 kV and 36 kV, is essential for managing power in industrial systems. It controls electricity flow, protects against faults, and isolates circuits for safe maintenance. Modern systems integrate with automation platforms, offering real-time monitoring and predictive maintenance.

Key takeaways:

- Functions: Control, protection, and isolation of electrical circuits.

- Components: Circuit breakers (vacuum or SF6), busbars, relays, transformers, and disconnectors.

- Types: Air-insulated, gas-insulated, metal-clad, and metal-enclosed switchgear.

- Applications: Used in utilities, manufacturing, data centers, renewable energy, and more.

- Safety Standards: Compliance with ANSI, IEEE, and NFPA standards is critical.

- Selection Tips: Match voltage/load ratings, consider environmental conditions, and plan for future expansion.

Modern advancements include smart relays, SCADA integration, and arc-resistant designs for enhanced safety and reliability. Proper selection ensures long-term performance and reduced downtime.

Medium Voltage Switchgear Fundamentals: The Mini Course

Medium Voltage Switchgear Components and How They Work

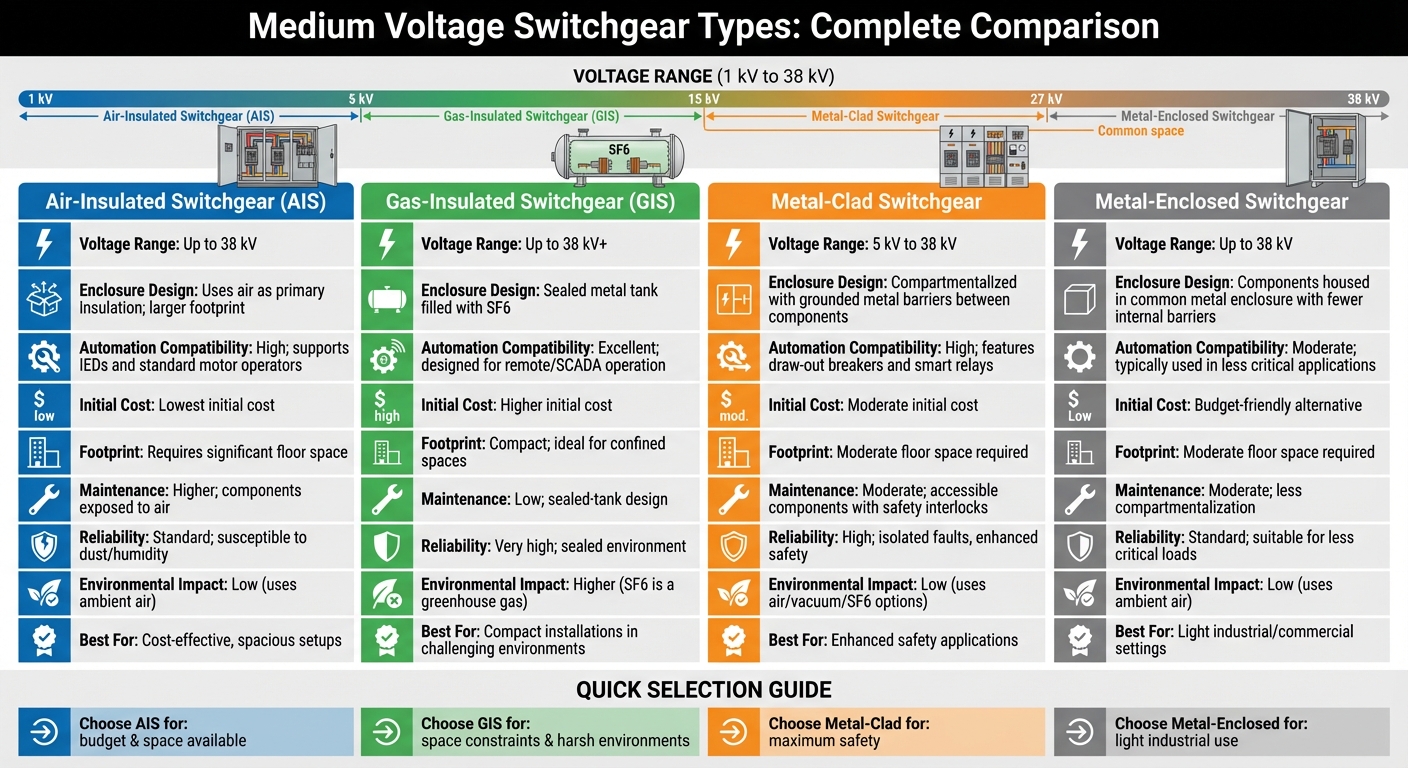

Medium Voltage Switchgear Types Comparison: AIS vs GIS vs Metal-Clad vs Metal-Enclosed

Medium voltage switchgear relies on a combination of sensors, microprocessor-based relays, and mechanical devices to manage and control the flow of power. Instrument transformers play a critical role here - current transformers (CTs) reduce the current, while voltage transformers (VTs) lower the voltage for monitoring and protection purposes. Protective relays process this data to identify system faults and activate the circuit breaker when necessary.

At the heart of the system are busbars, typically made from copper or aluminum, which serve as the primary backbone for power distribution, connecting various components within the switchgear. Disconnectors, also known as isolators, are used to create a visible gap in the circuit to ensure safe maintenance. However, these devices are not designed to interrupt load currents and must only be operated after the circuit breaker has been opened. Modern systems often include both manual controls (OTM) and automated controls (SEM). The automated systems are significantly faster, responding in approximately 100 milliseconds compared to the 5-second response time of manual controls.

Main Components of Medium Voltage Switchgear

The components below highlight how medium voltage switchgear systems ensure safe and efficient power distribution. Among the most commonly used circuit breakers in these systems are vacuum and SF6 types.

Vacuum circuit breakers use sealed vacuum bottles to extinguish arcs, requiring minimal maintenance. This makes them a more environmentally conscious choice. On the other hand, SF6 circuit breakers utilize sulfur hexafluoride gas, allowing for a compact design thanks to its excellent insulation properties. However, SF6 is a potent greenhouse gas, raising environmental concerns despite its low leakage rate - typically less than 0.1% of the total gas volume annually.

| Feature | Vacuum Circuit Breaker (VCB) | SF6 Circuit Breaker |

|---|---|---|

| Arc Quenching | Vacuum interrupter bottle | Sulfur Hexafluoride (SF6) gas |

| Maintenance | Low; sealed-for-life bottles | Low, but requires gas pressure monitoring |

| Size | Compact | Compact due to high dielectric strength |

| Environmental Impact | Minimal | High (SF6 is a potent greenhouse gas) |

Types of Medium Voltage Switchgear

Medium voltage switchgear comes in different types, each designed to meet specific operational and environmental needs.

- Air-Insulated Switchgear (AIS): This type uses air as the insulating medium, which makes it cost-effective but requires more space. It’s a preferred choice when space constraints aren’t a major concern.

- Gas-Insulated Switchgear (GIS): Featuring a sealed metal tank filled with SF6 gas, GIS is a compact solution well-suited for challenging environments, such as coastal areas or underground installations, where air-insulated systems might struggle with contaminants.

- Metal-Clad Switchgear: Known for its compartmentalized design, metal-clad switchgear separates the bus, breaker, and cables with grounded metal barriers. This design enhances safety and simplifies maintenance, as it often includes draw-out breakers.

- Metal-Enclosed Switchgear: In contrast, metal-enclosed switchgear houses all components within a single metal enclosure with fewer internal barriers. It’s typically used in less critical applications, such as light industrial or commercial settings.

| Type | Voltage Range | Enclosure Design | Automation Compatibility |

|---|---|---|---|

| Air-Insulated (AIS) | Up to 38 kV | Uses air as the primary insulation; larger footprint | High; supports IEDs and standard motor operators |

| Gas-Insulated (GIS) | Up to 38 kV+ | Sealed metal tank filled with SF6 | Excellent; designed for remote/SCADA operation |

| Metal-Clad | 5 kV to 38 kV | Compartmentalized with grounded metal barriers between components | High; features draw-out breakers and smart relays |

| Metal-Enclosed | Up to 38 kV | Components housed in a common metal enclosure with fewer internal barriers | Moderate; typically used in less critical applications |

Where Medium Voltage Switchgear Is Used in Industrial Automation

Medium voltage switchgear plays a crucial role in powering automated industries, ensuring quick fault isolation and continuous operation. Its ability to detect and isolate issues within milliseconds while keeping the rest of the system running makes it essential for maintaining efficiency and reliability in industrial environments.

Industries across the board rely on this technology to safeguard their operations and minimize disruptions.

Industry Applications

In sectors where uninterrupted power is critical, medium voltage switchgear is a key component. For instance, electric utilities use it extensively in transmission and distribution networks to manage power flow to urban areas. When a fault occurs, the switchgear isolates the affected section immediately, ensuring the rest of the grid remains stable and operational. Similarly, manufacturing and industrial plants depend on switchgear to power large motors and production lines. It allows specific areas to be de-energized for maintenance without shutting down entire operations, reducing downtime.

Data centers are another major user, relying on medium voltage switchgear to maintain a steady power supply and support backup systems. This is critical to avoiding outages in environments where system reliability is non-negotiable. In the oil, gas, and chemical industries, switchgear is tasked with managing energy demands and protecting motors, especially in hazardous conditions where failures can lead to serious consequences. Water and wastewater treatment facilities also benefit from these systems, which regulate pumps and shield electrical components from moisture and corrosion.

The renewable energy sector uses medium voltage switchgear to link solar farms and wind turbines to the grid. This ensures a stable power flow even with fluctuating energy outputs. Meanwhile, transportation infrastructure, such as airports and railways, incorporates switchgear into systems for signaling, lighting, and centralized power distribution. Large commercial buildings also rely on it to efficiently manage HVAC systems and other building services.

| Industry | Primary Application | Key Benefit |

|---|---|---|

| Utilities | Distribution and transmission substations | Fault isolation and grid stability |

| Manufacturing | Large motor control and production lines | Equipment protection and reduced downtime |

| Data Centers | Power reliability and backup system support | Prevention of critical outages |

| Renewable Energy | Grid integration for solar and wind farms | Stable connection for variable outputs |

| Water Management | Pump and treatment system regulation | Protection against moisture and corrosion |

| Transportation | Railway signaling and airport lighting | Centralized control of key infrastructure |

Modern advancements have further enhanced the functionality of medium voltage switchgear. Today’s systems often include sensors and microprocessor-based relays that integrate seamlessly with SCADA or energy management platforms. This connectivity enables predictive maintenance, ensuring greater reliability and efficiency across automated industries.

Safety Standards and Compliance Requirements

In the U.S., medium voltage switchgear must adhere to strict safety and performance standards. The ANSI/IEEE C37 series forms the foundation for compliance. For instance, IEEE C37.20.2 outlines requirements for metal-clad switchgear, while IEEE C37.20.3 focuses on metal-enclosed interrupter switchgear. These standards define construction and performance criteria, ensuring the equipment meets the rigorous demands of industrial automation.

Another key standard, IEEE C37.20.7, specifies arc-resistant testing. This ensures switchgear can withstand internal arcing faults while safeguarding personnel. Arc-resistant protection is categorized into three types: Type A protects the front, Type B extends protection to the front and sides, and Type C includes the front, sides, and internal compartments. However, equipment only qualifies as arc-resistant if it meets these criteria with all doors and covers securely closed.

Beyond equipment standards, OSHA and NFPA 70E establish safety protocols for personnel working with medium voltage equipment rated above 1,000 V. Additionally, ANSI C37.2 standardizes device function numbers, such as 50/51 for overcurrent protection, bridging the gap between equipment design and modern automation needs. These regulations create a framework that ensures safety and operational reliability in automation environments.

Required Standards and Regulations

Switchgear must meet specific electrical requirements to prevent failures during voltage surges or faults. Basic Insulation Level (BIL) ratings define the insulation strength required for each voltage class. For example:

- A 5 kV system requires a 60 kV BIL.

- A 15 kV system needs a 95 kV BIL.

- A 25 kV system uses a 125 kV BIL.

- A 38 kV system requires a 150 kV BIL.

Altitude also impacts performance. Equipment installed above 1,000 meters requires derating, with voltage ratings reduced to 80% and current ratings to 96% at 3,000 meters. Meanwhile, NEMA standards provide testing procedures for indoor AC medium voltage switches and metal-clad assemblies, ensuring compliance with national safety benchmarks. When selecting switchgear, it’s crucial to verify that components like surge arresters and cable terminations are compatible with the switchgear’s BIL to avoid insulation failures.

Safety Features in Modern Switchgear

Modern switchgear incorporates multiple safety layers to protect both personnel and equipment. Arc-resistant designs channel fault energy through internal ducts or plenums to safe areas. Remote racking systems allow operators to manage circuit breakers from 25 to 30 feet away, keeping them outside the arc-flash boundary during operations.

Mechanical and key interlocks add another layer of safety by preventing actions like racking a closed breaker or opening an energized door. High-speed relays can clear faults in under 50 milliseconds (three cycles at 60 Hz). Advanced arc-flash detection systems, which combine light sensors with current monitoring, further reduce fault clearing times.

Modern switchgear also integrates with automation platforms through protocols like IEC 61850, Modbus, and DNP3. These enable intelligent electronic devices (IEDs) to provide real-time monitoring, diagnostics, and predictive maintenance. Microprocessor-based relays can be set to "maintenance mode" during servicing, reducing potential incident energy levels. Additionally, Ground and Test Devices (GATD) offer a safe way to ground the main bus or external circuits during maintenance. Finally, pressure relief systems, such as top-mounted vents or flaps, release internal pressure during faults to prevent enclosure damage.

These advanced features work alongside technical standards to ensure safe and reliable operation in industrial automation settings.

sbb-itb-501186b

How to Select Medium Voltage Switchgear for Automation

Selection Criteria

Choosing the right medium voltage switchgear for automation involves aligning technical specifications with your system's operational needs. Start by ensuring the switchgear's voltage and load ratings are compatible with your setup. For systems rated between 1 kV and 38 kV, the switchgear's voltage must meet or exceed the incoming system voltage. Eric Gersh, General Manager at Southwest Electric, highlights the importance of this step:

The gear's voltage rating must align with the incoming system voltage from the utility. Therefore, when requesting new or replacement switchgear, it's important to conduct a thorough analysis of both current and anticipated load demands.

Another critical factor is fault current capacity, which must handle both short-time withstand (Ik) and peak withstand (Ip) currents. For 60 Hz installations, common in the U.S., the peak withstand current is typically 2.6 times the rated short-time withstand current. Vacuum circuit breakers, widely used in these setups, generally offer interrupt ratings ranging from 25 kAIC to 63 kAIC symmetrical. To determine your specific requirements, perform a short circuit analysis and an arc flash study before making a purchase.

The environment also plays a key role in switchgear selection. For indoor applications, NEMA 1 or 12 enclosures are standard. Outdoor or harsher environments demand NEMA 3R or 4 enclosures, which can withstand humidity, dust, and extreme conditions. If operating temperatures exceed 104°F (40°C), you'll need to adjust the switchgear's current capacity according to IEC 62271-1 standards.

The type of insulation impacts both cost and space requirements. Air-insulated switchgear (AIS) is the most affordable but requires more room. Gas-insulated switchgear (GIS), which uses SF6 gas, offers a compact, reliable design but comes with a higher initial cost and concerns about greenhouse gas emissions. Solid-dielectric-in-air technology offers a middle ground, combining low maintenance with competitive pricing.

| Feature | Air-Insulated Switchgear (AIS) | Gas-Insulated Switchgear (GIS) |

|---|---|---|

| Initial Cost | Lowest initial cost | Higher initial cost |

| Footprint | Requires significant floor space | Compact; ideal for confined spaces |

| Maintenance | Higher; components exposed to air | Low; sealed-tank design |

| Reliability | Standard; susceptible to dust/humidity | Very high; sealed environment |

| Environmental Impact | Low (uses ambient air) | Higher (SF6 is a greenhouse gas) |

Planning for future growth is another important consideration. Modular designs allow for easier upgrades without replacing the entire switchgear lineup. Facilities with space constraints can benefit from front-accessible switchgear, which can be installed directly against a wall to save floor space.

Connecting Switchgear to Automation Systems

Modern switchgear integrates seamlessly with automation systems through Intelligent Electronic Devices (IEDs) such as microprocessor-based relays, smart sensors, and motorized switches. These components monitor real-time parameters like current, voltage, and frequency by processing signals from current transformers (CTs) and voltage transformers (VTs). The data is then sent to SCADA systems, PLCs, and energy management platforms for centralized monitoring and control.

Communication protocols like IEC 61850, Modbus, and DNP3 enable automated processes such as load transfers, circuit switching, and rapid fault isolation, eliminating the need for manual intervention. Additionally, networked switchgear supports cloud-based analytics, offering insights that enhance both safety and operational efficiency.

Remote operation is another advantage, allowing operators to manage circuit breakers from a safe distance - typically 25 to 30 feet away - keeping them outside the arc-flash boundary. This level of integration makes switchgear a vital component in modern automated systems, ensuring reliability and safety in industrial operations.

Where to Buy Medium Voltage Switchgear

Once you've nailed down your technical requirements, the next step is finding the right place to source your medium voltage switchgear. It's not just about buying equipment - it’s about ensuring the gear meets safety standards and fits your project’s specific needs. Whether you're looking for new or used options, the key is to prioritize quality and compliance. Eric Gersh, General Manager at Southwest Electric Co., underscores the importance of this investment:

As with any major equipment investment, you get what you pay for - and switchgear is no exception. These are critical, high-value components that play a central role in safety and protection.

To ensure your equipment is up to standard, verify that it complies with industry regulations like ANSI, IEEE, IEC, OSHA, and NFPA. Additionally, check for NEMA ratings appropriate for your operating environment. Reliable vendors will also offer support for replacement parts, future expansions, and detailed documentation, all of which contribute to long-term reliability and ease of use.

Why Choose Electrical Trader

If you're looking for a dependable source, Electrical Trader is worth considering. This online marketplace offers a wide range of new and used medium voltage switchgear, tailored to meet the demands of industrial automation projects. It’s especially helpful for those seeking cost-effective solutions or quick replacements to minimize downtime.

Electrical Trader also supports the shift toward advanced systems, providing equipment compatible with smart sensors and microprocessor-based relays for remote monitoring and diagnostics. Their inventory includes products designed to handle specific voltage ratings - typically ranging from 600 A to 4,000 A continuous current - and various environmental conditions.

For used equipment, it’s essential to perform thorough inspections. Look for signs of wear, rust, or damage, and test insulation resistance along with circuit breaker functionality before installation. This ensures the equipment is ready to meet your operational needs without unexpected issues.

Conclusion

Medium voltage switchgear plays a critical role in industrial automation, managing power levels from 1 kV to 36 kV while safeguarding equipment against faults and overloads. Understanding these components is essential for developing an effective automation strategy. Modern advancements, like Intelligent Electronic Devices (IEDs) and microprocessor-based relays, now integrate with SCADA platforms, enabling predictive maintenance and improved system control.

When selecting equipment, it's vital to perform short-circuit and arc flash analyses, choose NEMA enclosures suited to your environment, and plan for future system growth.

Different switchgear types serve specific needs: AIS is ideal for cost-effective, spacious setups, GIS suits compact installations in challenging environments, and metal-clad switchgear enhances safety, while metal-enclosed options provide a budget-friendly alternative.

Compliance with standards such as ANSI, IEEE, IEC, OSHA, and NFPA is non-negotiable. Incorporating arc-resistant designs, high-speed relays (under 50 milliseconds), and appropriate BIL ratings further ensures system reliability and safety. As Eric Gersh from Southwest Electric Co. aptly puts it:

Choosing the right switchgear is more than just matching specifications - it's about ensuring the long-term safety, reliability, and efficiency of your entire electrical system.

For reliable performance, source switchgear from vendors who provide compliance documentation, replacement parts, and thorough testing. High-quality switchgear is the foundation for uninterrupted and secure industrial automation.

FAQs

What environmental concerns are associated with using SF6 in medium voltage switchgear?

SF₆ (sulfur hexafluoride) is a popular insulating gas used in medium voltage switchgear. However, it comes with serious environmental concerns. Its global warming potential (GWP) is staggering - about 22,800 times higher than carbon dioxide over a 100-year period. This means that even small leaks during operation, maintenance, or disposal can have a considerable impact on greenhouse gas emissions.

Beyond its environmental impact, SF₆ can also break down into harmful by-products when exposed to electrical faults. These by-products not only pose safety hazards but also add to environmental risks. Because of these issues, there's a growing movement toward SF₆-free technologies. Alternatives like air-insulated or vacuum switchgear are emerging as safer, more sustainable options for medium voltage applications.

How does integrating SCADA improve the performance of medium voltage switchgear?

Integrating SCADA (Supervisory Control and Data Acquisition) with medium voltage switchgear brings a host of benefits, including remote monitoring, control, and automation. With SCADA, operators can access real-time data from critical components like circuit breakers and protection devices. This not only boosts reliability but also enhances safety by enabling faster fault detection and response.

Another key advantage is automated fault isolation and power rerouting. This feature helps minimize downtime and reduces the risk of extensive damage. SCADA systems also gather and analyze performance data, which is invaluable for predictive maintenance and streamlining operations. By transforming traditional switchgear into smart, automated systems, SCADA significantly improves efficiency, reliability, and safety in both industrial and utility settings.

What should you consider when choosing medium voltage switchgear for tough environments?

When choosing medium voltage switchgear for tough environments, focusing on durability, safety, and consistent performance is key. Start by reviewing the ingress protection (IP) rating, which measures how well the equipment resists dust, water, and other environmental factors. For areas prone to high moisture, dust, or water exposure, a higher IP rating is a must.

Environmental challenges like extreme temperatures, corrosive atmospheres, and vibrations also influence your decision. For example, corrosion-resistant coatings or sealed enclosures work well in coastal or industrial areas. Additionally, deciding between air-insulated (AIS) and gas-insulated (GIS) switchgear is important - GIS offers a compact design, making it ideal for tight spaces or environments with contamination concerns.

Lastly, consider the switchgear's overall construction, its ease of maintenance, and its ability to withstand stresses like seismic activity. Addressing these aspects ensures reliable and safe operation, even in the most demanding conditions.