5 Key Safety Steps Before Synchronizing Generators

Share

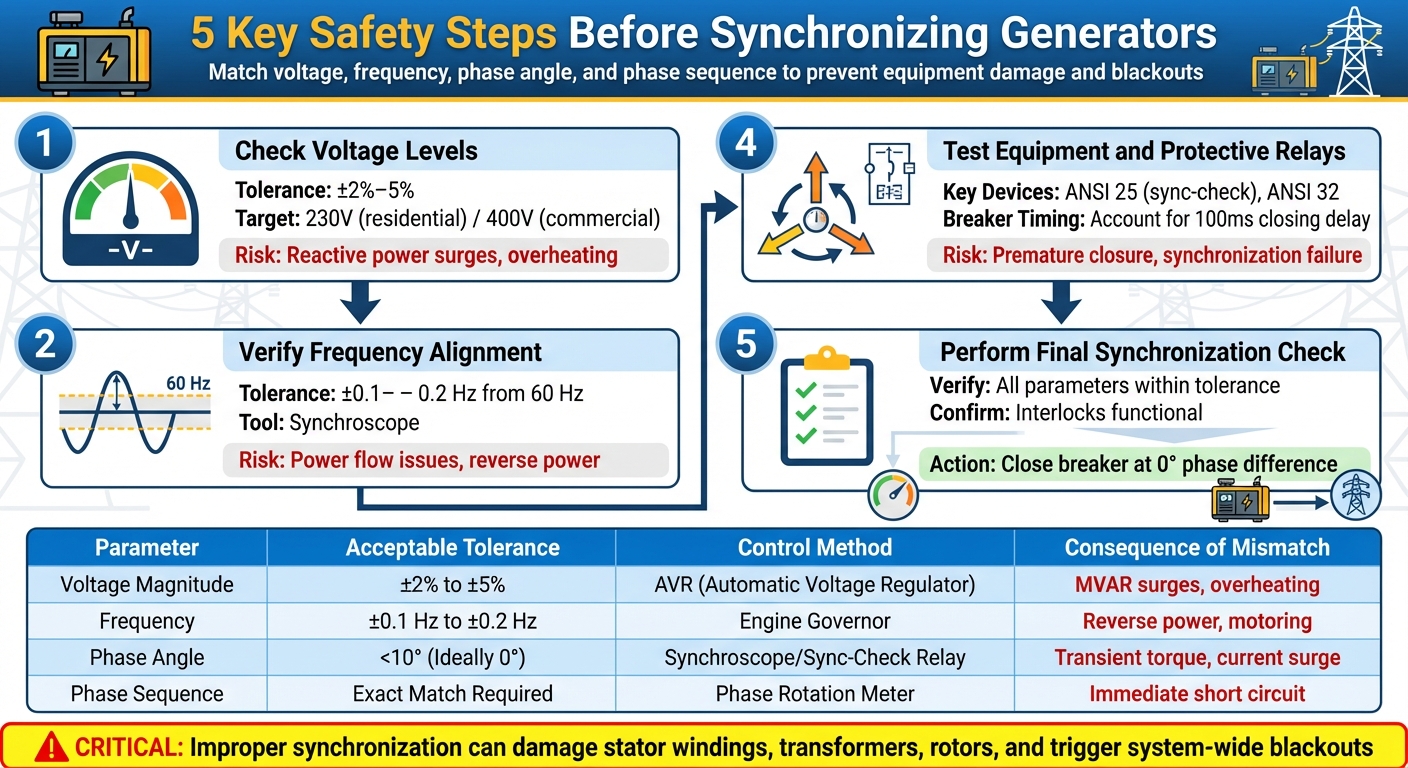

Synchronizing generators with a power system is a precise process that ensures the generator matches the grid in voltage, frequency, phase angle, and phase sequence. Even small mismatches can cause severe electrical surges, mechanical stress, and system-wide failures. Here's a quick overview of the five essential steps to ensure safe synchronization:

- Check Voltage Levels: Match the generator's voltage to the grid within a ±2%–5% range to avoid reactive power surges.

- Verify Frequency Alignment: Ensure the generator's frequency is within ±0.1–0.2 Hz of the grid's 60 Hz standard to prevent power flow issues.

- Confirm Phase Sequence and Angle: Align the generator's phase sequence and minimize the phase angle difference to prevent short circuits or mechanical shocks.

- Test Equipment and Protective Relays: Verify all monitoring tools and relays, such as synchroscopes and sync-check relays, are functional to block unsafe breaker closures.

- Perform Final Synchronization Check: Double-check all parameters and interlocks before closing the breaker to ensure a smooth connection.

Why it matters: Improper synchronization can damage equipment like stator windings, transformers, and rotors, and even trigger blackouts. Following these steps protects your system and ensures reliable operation.

Generator Synchronization Parameters: Tolerances and Control Methods

1. Check Voltage Levels Match

Voltage Compatibility

Make sure the generator's RMS voltage aligns with the bus voltage, staying within a ±2%–5% tolerance range. For most residential setups, this means aiming for 230 V, while commercial and industrial grids typically operate near 400 V.

Once you've identified the proper voltage range, measure the generator's output with precision. Use calibrated voltmeters to get accurate readings, and adjust the AVR (Automatic Voltage Regulator) or field rheostat as needed. This step is crucial to prevent reactive power surges.

"If the generator's voltage is too high, it will cause a massive surge of reactive power (VARs) into the system, leading to overheating and potential damage." – Gretech Power

When the generator's voltage is higher than the grid's, it becomes overexcited, pushing MVARs (megavolt-amperes reactive) into the system, which can lead to overheating. On the other hand, if the voltage is too low, the generator under-excites, absorbing MVARs and increasing the risk of stator winding and insulation damage. Keeping the voltage within the proper range avoids these harmful scenarios.

To add a layer of protection, configure the synchronism-check relay (ANSI Device 25) to block breaker closure if voltage differences exceed the acceptable limits. This prevents disturbances and unnecessary relay trips. Once voltage levels are balanced, you can move on to checking frequency alignment.

2. Verify Frequency Alignment

Frequency Synchronization

To ensure proper integration with the North American grid, the generator's frequency must align within ±0.1–0.2 Hz of the grid's standard 60 Hz (±0.5 Hz). This can be achieved by fine-tuning the prime mover's governor. This step lays the groundwork for additional adjustments using standard monitoring tools.

A common approach is to set the generator's frequency slightly higher than the grid's. Why? When the breaker closes, this ensures the generator immediately starts supplying real power instead of behaving like a motor and drawing power from the grid. If the generator runs slower than the grid, it risks abrupt acceleration, which could trigger reverse power activation.

As Edvard Csanyi, Founder of Electrical Engineering Portal, explains:

"If closed when slower than the grid, the generator would be out of step with the external electrical system. It would behave like motor and the grid would try to bring it up to speed."

To monitor the frequency, use a synchroscope. If the needle moves clockwise, the generator is running faster than the grid; if it moves counter-clockwise, it's slower. Adjust the governor until the needle approaches the 12 o'clock position. This accounts for any mechanical lag before closing the breaker.

Modern auto-synchronizers have made this process even more precise. By sampling waveforms and pulsing the governor, they ensure smoother adjustments, reducing the risk of massive current surges or torsional stress that could harm the generator.

3. Confirm Phase Sequence and Angle

Phase Sequence Accuracy

Phase sequence is a critical check that ensures the incoming generator's wiring matches the bus bar's rotation. The phase rotation (L1, L2, L3) of the generator must align perfectly with the bus bar - typically ABC to ABC. A mismatch in phase sequence can result in an immediate short circuit.

When the sequence is incorrect, it’s like having two phases 120° out of sync, leading to severe electrical and mechanical shocks. To avoid this, a phase-sequence meter should be used during installation to confirm the correct rotation. Once verified, the wiring should remain untouched unless changes are made later.

For manual synchronization using lamps, the lamp behavior provides clues about the phase sequence. If the lamps flash on and off together, the sequence is correct. However, if they flicker in a "rolling dark" pattern, the sequence is wrong. In such cases, simply swap any two of the three leads on the generator to fix the sequence.

After confirming the phase sequence, focus on minimizing the phase angle. The phase angle refers to the timing difference between the voltage waves of the generator and the grid. Ideally, this angle should be as close to zero as possible. Closing the breaker when there’s a significant phase angle difference can cause violent alignment, resulting in power surges and mechanical stress. Most relay settings permit a phase angle difference of less than 10° to 15°, but the best practice is to aim for 0°. For advanced closed-transition switches, the allowable error may be as low as 5°.

To ensure safety, use a synchronism-check relay (ANSI 25), which prevents breaker closure if the phase angle or other parameters are outside acceptable limits. If synchronizing manually with a synchroscope, close the breaker just before the 12 o’clock position to compensate for mechanical delays.

4. Test Equipment and Protective Relays

Equipment Readiness

Once you've verified the parameters, it's time to ensure all related equipment and interlocks are fully functional. After confirming voltage, frequency, and phase alignment, test all monitoring and control devices to guarantee safe synchronization. Tools like synchroscopes, voltmeters, and frequency meters need to be properly calibrated and operational to accurately monitor the relationship between the generator and the bus. Precision here is non-negotiable.

Pay close attention to the circuit breaker's mechanical closing time. Automatic synchronizers account for this delay by triggering the breaker slightly before the 12 o'clock position, ensuring the contacts meet at a 0° phase difference. For instance, if your breaker has a 100-millisecond closing time, the synchronizer will adjust accordingly. Measure and program this timing accurately to avoid synchronization errors.

Additionally, test the generator's governor and AVR (Automatic Voltage Regulator) to confirm they respond promptly to synchronizer commands. These systems are critical for real-time adjustments to frequency and voltage during synchronization. If either is slow or unresponsive, maintaining the precise tolerances required for safe synchronization becomes impossible.

Interlock Functionality

The synchronism-check relay (ANSI Device 25) plays a vital role in preventing breaker closure when parameters fall outside safe limits. The IEEE Power System Relaying and Control Committee emphasizes the importance of this:

"A synchronizing system that is designed and verified to operate within a generator's synchronizing limits is critical in helping maintain the life of generating plant assets and improving stability of the power system."

To confirm proper relay operation, use secondary injection test sets like the Megger SMRT36 for both steady-state and dynamic testing. This ensures the relay will block closure if the parameters deviate from acceptable ranges.

Integrate the sync-check relay with manual controls to prevent premature breaker closure. Operators can sometimes act impatiently or make errors, but the relay ensures that even if someone attempts to close the breaker too early, the system will block the action. A 2024 IEEE technical report highlighted a case where a generator step-up transformer failed due to out-of-phase synchronization. The first incident weakened the insulation, and a subsequent out-of-phase closure destroyed the transformer entirely. Such failures are entirely avoidable with properly tested interlocks.

Also, ensure that the Reverse Power relay (ANSI 32) and Loss of Field relay (ANSI 40) are active and thoroughly tested. These relays are critical for tripping the generator offline if synchronization fails, preventing issues like motoring from the grid or absorbing excessive reactive power.

Once all equipment and protective relays are verified, you're ready to proceed to the final synchronization check.

sbb-itb-501186b

Generator Synchronization (Full Lecture)

5. Complete Final Synchronization Check and Interlocks

Before closing the breaker, it's crucial to perform a final check of all synchronization parameters. This ensures safe operation and proper interlocking.

Voltage Compatibility

Double-check that the generator's RMS voltage is within ±5% of the bus voltage. Use the Automatic Voltage Regulator (AVR) and a calibrated voltmeter to make this assessment.

Frequency Synchronization

The generator's frequency should closely match the grid's 60 Hz frequency. Aim for a slight positive slip of about +0.1 Hz, meaning the generator should run just a bit faster than the bus. The synchronism-check relay will only allow breaker closure if the frequency difference is within ±0.1 to ±0.2 Hz. Keep an eye on the synchroscope - it should rotate slowly clockwise, indicating proper synchronization.

Phase Sequence Accuracy

Using a phase rotation meter, confirm that the generator’s phase rotation (A-B-C) matches the grid exactly. This step is critical because interlocks cannot correct reversed wiring. A mismatch here can cause a severe short circuit the moment the breaker closes.

Interlock Functionality

The synchronism-check relay (ANSI Device 25) acts as the final safeguard. This device monitors voltage, frequency, and phase angle simultaneously and prevents the breaker from closing if any parameter is outside safe limits. Typically, it allows a phase angle error of less than 10° to 20°.

"When an interlock switch is properly installed, it prevents the generator circuit breaker and the main circuit breaker from both being on at the same time."

For portable setups, mechanical interlock kits are a safer choice than using extension cords, as they prevent dangerous backfeeding. Test the interlock by deliberately setting parameters outside acceptable limits to ensure the close circuit is interrupted. This safeguard is especially critical during manual synchronization, where human error could lead to premature breaker closure.

| Parameter | Acceptable Tolerance | Control Method |

|---|---|---|

| Voltage Magnitude | ±2% to ±5% | Automatic Voltage Regulator (AVR) |

| Frequency | ±0.1 Hz to ±0.2 Hz | Engine Governor / Throttle |

| Phase Angle | <10° (Ideally 0°) | Synchroscope / Sync-Check Relay |

| Phase Sequence | No tolerance (Exact) | Phase Rotation Meter / Wiring Check |

After verifying all parameters and confirming the interlocks are functioning, you can proceed to close the breaker. To ensure the contacts meet at 0° phase difference, account for the breaker’s 100-millisecond closing time when making adjustments. This final step ties together all previous checks, ensuring a smooth and secure connection to the grid.

Conclusion

Skipping pre-synchronization checks can lead to serious risks. Without proper synchronization, extreme transient torque can cause mechanical failures, damaging generator shafts, prime movers, and other rotating components. At the same time, large current in-rushes can harm windings, stator and rotor assemblies, and step-up transformers. These synchronization errors introduce electrical and mechanical transients that ripple through the entire power system, from prime movers to transformers.

Voltage or phase mismatches further compound these risks, destabilizing the grid, tripping substation breakers, and even causing blackouts. A generator operating 180° out of phase can exert a destructive force. The consequences can be severe, including arc flash explosions that pose life-threatening hazards to personnel.

To mitigate these dangers, protective relays like synchronism-check relays (ANSI Device 25) serve as a critical safety measure. They monitor voltage, frequency, and phase angle to prevent unsafe breaker closures. Automatic synchronizers add another layer of protection by using digital precision to calculate the exact moment for breaker activation, accounting for contact closing time and reducing the chance of human error.

For reliable synchronization tools, Electrical Trader offers a range of equipment, including protective relays and generators, ensuring all key parameters - voltage, frequency, phase angle, and phase sequence - are perfectly aligned. Whether you're setting up a new system or maintaining an existing one, sourcing dependable tools from Electrical Trader helps prevent failures and keeps your power systems operating safely.

Following these pre-synchronization measures is crucial to protecting both equipment and personnel while maintaining a stable and reliable power grid.

FAQs

Why is it necessary to match a generator's voltage with the grid's voltage before synchronization?

Matching the generator's voltage with the grid's voltage is crucial for a safe and seamless connection. This alignment prevents issues like power surges, electrical disruptions, or potential damage to both the generator and any connected equipment.

Proper voltage synchronization also plays a key role in maintaining system stability. It minimizes operational risks, safeguarding both the infrastructure and the people working with it.

What happens if the phase sequence is incorrect during generator synchronization?

An incorrect phase sequence during generator synchronization can cause serious electrical and mechanical problems. These issues might include sudden transients that can harm the generator, transformers, or other connected components in the power system. Beyond the physical damage, such mistakes can lead to expensive repairs and operational downtime. This makes it essential to confirm the phase sequence before proceeding with synchronization.

What role do synchronism-check relays play in ensuring safe generator synchronization?

Synchronism-check relays are essential for the safe synchronization of generators. They work by constantly monitoring critical parameters such as voltage, frequency, and phase angle. If these parameters show that the generators are out of phase during synchronization, the relays step in to prevent potential damage.

These relays can issue alarms or even initiate trips to protect the equipment. By identifying mismatches in real time, they not only guard against equipment failure but also help maintain overall system stability. This makes them a key component in ensuring generators operate safely and efficiently.