Top IEEE 446-1995 Recommendations for Standby Power

Share

IEEE 446-1995 is a guide for designing, installing, and maintaining emergency and standby power systems in industrial and commercial setups. Although marked "Inactive-Reserved" in 2021, it remains a trusted reference for engineers. Here's what you need to know:

- Power Sources: Recommends generators for long-term outages and batteries (UPS) for instant power needs. Hybrid systems combining both are gaining traction for reliability.

- Load Assessment: Accurate load analysis ensures system stability, especially for motor inrush currents and peak operations.

- Safety: Overcurrent protection, short-circuit analysis, and proper grounding prevent system damage and ensure worker safety.

- Maintenance: Regular inspections, load testing, and tracking performance metrics like MTBF are critical for reliability.

- Industry Focus: Hospitals need rapid response (e.g., within 10 seconds), while data centers prioritize redundancy (e.g., N+1 configurations). Industrial facilities face challenges like motor-starting currents and voltage dips.

Quick Takeaway

This standard outlines everything from power source selection to maintenance protocols, helping facilities stay functional during outages. Whether you're in healthcare, manufacturing, or IT, IEEE 446-1995 offers specific guidance tailored to your needs.

Critical power: Backup, standby and emergency power in mission critical facilities

Power Source Selection Recommendations

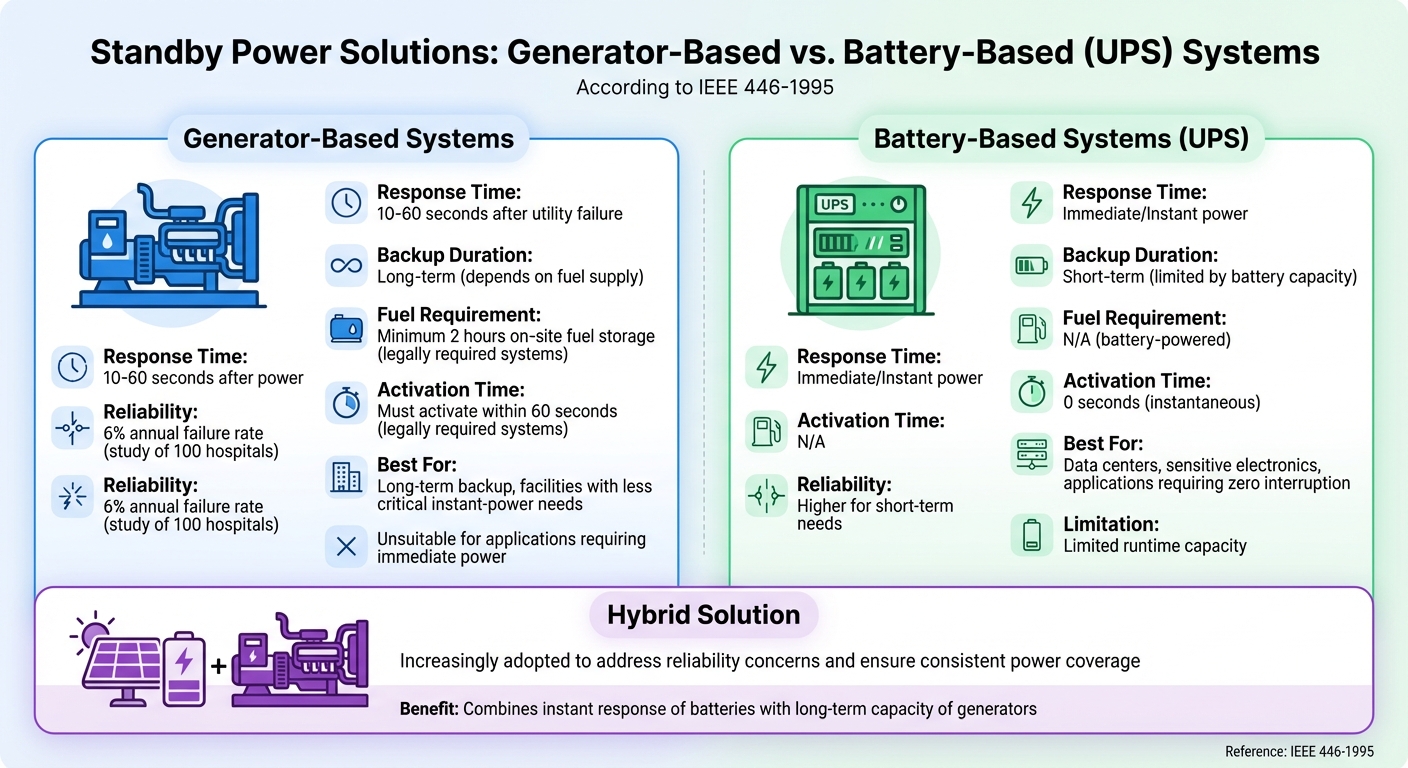

Generator vs Battery Standby Power Systems Comparison

Generators vs. Batteries

When designing a standby power system, IEEE 446-1995 provides a clear framework for selecting between generator-based systems and battery-based systems, based on factors like response time and backup duration.

Generator systems typically take 10–60 seconds to start after a utility failure. While this delay makes them unsuitable for applications requiring instant power, they are a solid choice for long-term backup, as they rely on on-site fuel supplies. For legally required standby systems, generators must activate within 60 seconds and store at least two hours of fuel.

On the other hand, battery systems (UPS) provide immediate power. This makes them indispensable for environments like data centers or sensitive electronic setups, where even a brief power interruption can lead to significant disruptions. However, their runtime is limited by battery capacity, making them best suited for short-term backup scenarios.

Interestingly, a statistical study of 100 hospitals showed a 6% failure rate for diesel generator sets annually, even with regular maintenance. This reliability issue has driven many facilities to adopt hybrid systems that combine PV/battery setups with diesel generators, ensuring more consistent power coverage.

Once the type of power source is selected, an accurate load assessment becomes crucial to ensure the system operates reliably.

Load Assessment Requirements

Precise load assessment is critical for determining the system's stability. This involves measuring both steady-state and transient loads, particularly motor inrush currents. To calculate total kilowatt requirements, the standard recommends attaching ammeters to each leg of the electrical service during peak operations.

When sizing generators, it’s essential to account for the largest motor starting kVA to prevent voltage dips that could disrupt other equipment. Standby generator ratings must also maintain a power factor of no more than 0.7. If the generator cannot support all connected loads simultaneously, the system must be designed to shed non-critical loads.

Loads must be classified according to NEC/NFPA standards under three categories: Emergency, Legally Required, or Optional. This classification helps determine the required reliability and response time for each load. Additionally, the standard advises against relying solely on public utility gas or municipal water supplies for prime movers, as these sources fail to meet NEC reliability benchmarks for standby systems.

Protection and Safety Requirements

Overcurrent and Short Circuit Protection

Chapter 6 of IEEE 446-1995 focuses on safeguarding power sources and switching equipment during fault conditions. The standard stresses the importance of using coordinated protective devices to limit system damage and reduce service disruptions. To achieve this, it recommends tools like low-voltage power circuit breakers, molded-case circuit breakers (MCCBs), and various types of fuses to handle overloads and short circuits. Circuit breakers that meet ANSI/UL 489 standards provide resettable protection with adjustable trip settings, while high-interrupting capacity fuses (UL 198C) are designed to limit current in areas prone to high faults.

"System protection and coordination serve to minimize damage to a system and its components, thereby limiting the extent and duration of any service interruption occurring on any portion of the system." - IEEE Std 242

Protective devices should be rated for the fault currents identified during system analysis. IEEE 242 outlines detailed methods for short-circuit analysis, ensuring that systems are equipped to handle fault conditions effectively. Additionally, the inclusion of ground-fault protective devices is emphasized to boost equipment safety and reliability.

These measures form the foundation for implementing effective emergency shutdown and isolation protocols.

Emergency Shutdown and Isolation

IEEE 446-1995 builds on the concept of protective device coordination by outlining strategies for emergency shutdown and isolation. This includes the use of circuit breakers, fuses, and disconnecting devices to ensure safe operation. Automatic Transfer Switches (ATS) are particularly critical, as they prevent the standby power source and utility service from operating simultaneously. These switches must comply with ANSI/UL 1008 standards and be listed specifically for emergency or legally required standby systems.

"There must be a transfer switch so that the service and the alternate source of power cannot operate simultaneously. This protects electricians and linemen from electric shock hazards." - Robert Key, JADE Learning

Proper coordination between isolation devices and overcurrent protective devices is essential to avoid nuisance tripping. Beyond addressing electrical faults, these isolation strategies also mitigate risks like energizing utility lines during maintenance or emergencies, ensuring a safer environment for both workers and the system.

System Grounding Design

Chapter 7 of IEEE 446-1995 provides detailed guidance on grounding standby systems to ensure both safety and stability. Grounding plays a critical role in keeping earth voltage at safe levels and creating a fault current path for protective devices. This becomes especially important when switching between utility power and standby power sources. Without proper grounding, issues like neutral current circulation or false ground-fault detection can arise, potentially compromising the system's reliability. The choice of grounding method is directly influenced by this foundational grounding approach.

Grounding Methods

IEEE 446-1995 describes three main grounding methods: solid, high-resistance, and low-resistance grounding. Each method is selected based on factors like system voltage, fault current needs, and the desired level of operational continuity:

- Solid Grounding: In this method, the neutral is directly connected to the earth, resulting in high fault currents that quickly trip circuit breakers. This approach is commonly used in low-voltage commercial buildings.

- High-Resistance Grounding: This method limits fault current to very low levels, which helps minimize equipment damage. It also allows industrial facilities to continue operating during a single ground fault without requiring an immediate shutdown.

- Low-Resistance Grounding: By limiting fault current to moderate levels (e.g., 200–400 amps), this method is well-suited for medium-voltage systems.

For a deeper understanding of grounding principles, engineers are encouraged to consult IEEE 142, also known as the "Green Book". When designing standby systems, it's essential to determine whether the power source qualifies as a "separately derived system" under the NEC. This classification dictates where neutral-to-ground bonding should occur - either at the generator or the service entrance.

US Electrical Code Compliance

Choosing the right grounding method is just one part of the equation; compliance with the National Electrical Code (NEC) is equally critical. IEEE 446-1995 was developed to align with NEC (NFPA 70) standards, ensuring that standby power installations meet US safety requirements. The standard addresses two key aspects of grounding:

- System Grounding: Connecting the power source neutral or phase to the earth.

- Equipment Grounding: Bonding non-current-carrying metallic components, such as frames and enclosures, to the grounding system.

Proper grounding is essential for reducing shock risks, providing a reliable fault current path, and enabling overcurrent devices to operate effectively. NEC compliance also determines whether a system is classified as separately derived, which directly impacts the bonding requirements for the neutral conductor.

To maintain effective grounding connections, Chapter 8 of IEEE 446 highlights the importance of routine maintenance and testing of grounding systems. Regular checks ensure that the grounding infrastructure remains reliable and continues to meet safety standards over time.

sbb-itb-501186b

Maintenance and Testing Procedures

Chapter 8 of IEEE 446-1995 lays out detailed maintenance practices for emergency and standby power systems. One key challenge it addresses is the risk of latent failures in standby systems due to long periods of inactivity. The standard stresses that maintenance is just as critical as system design when it comes to achieving reliability goals.

The importance of proper maintenance can't be overstated. IEEE 446-1995 ties these procedures directly to the reliability objectives outlined in Chapter 10. The recommendations cover both power sources, like generators and batteries, and switching equipment, ensuring they perform as needed during fault conditions. This makes systematic inspections and thorough load testing essential.

Routine Inspection Guidelines

Routine inspections are the first step in preventing system failures. IEEE 446-1995 suggests combining visual checks with operational tests to make sure all components are working properly and are ready to handle critical loads. These inspections can catch problems like slow start times, worn-out components, or equipment that's not available, stopping small issues from turning into major failures.

Visual checks should focus on spotting leaks, corrosion, loose connections, and any signs of wear or damage. Operational tests, on the other hand, ensure that automatic transfer switches (ATS) are functioning as expected and that generators start reliably. The standard also recommends tracking the Mean Time Between Failures (MTBF) for key components, using this data to adjust maintenance schedules based on real-world performance. Beyond inspections, load testing ensures the system can meet performance demands under actual operating conditions.

Generator Load Testing

Load testing is one of the most important maintenance tasks outlined in Chapter 8. This process evaluates whether the generator can handle its rated capacity without issues like voltage drops or frequency instability during a switch to emergency power. Unlike no-load tests, load testing replicates real operating conditions.

The standard advises performing load tests to confirm the system can maintain stable voltage and frequency levels while powering critical loads. This is crucial because system reliability depends more on configuration and redundancy than on upgrading individual components. Regular load testing can uncover problems like insufficient capacity, fuel system issues, or governor malfunctions - problems that may not show up during routine visual inspections.

Industry-Specific Power Requirements

IEEE 446-1995 goes beyond general maintenance practices by addressing the unique power needs of different industries. Chapter 9 highlights how power requirements vary significantly - for example, a hospital's life-safety systems demand a different approach than the production lines of a manufacturing plant. To accommodate these differences, IEEE 446-1995 integrates with standards like IEEE 602 for health care facilities and IEEE 1100 for data centers.

Hospitals and Data Centers

Health care facilities rely on uninterrupted power for critical areas such as patient monitoring, emergency lighting, and radiation safety. According to NEC Article 700, emergency generators in hospitals must be capable of handling loads within 10 seconds, and Critical Operations Power Systems (COPS) require a minimum of 72 hours of on-site fuel storage.

For data centers, IEEE 446-1995 classifies power systems into Off-Line, On-Line, and Real-Time categories, each with specific tolerances for power interruptions and quality. Uninterruptible Power Supply (UPS) systems are essential for bridging the gap during the 10–60 seconds it typically takes for standby generators to start and accept the load. Many modern data centers implement redundancy setups like N+1, N+2, or 2N configurations to prevent single points of failure during maintenance or equipment malfunctions. To meet the demands of continuous 24/7 operations, generator manufacturers now offer specialized ratings such as "Mission Critical Standby" or "Data Center Continuous".

While hospitals and data centers focus on rapid response and redundancy, industrial facilities face their own distinct challenges.

Industrial and Manufacturing Applications

Industrial facilities must contend with issues like motor-starting currents, voltage drops, and harmonic distortions, all of which can disrupt sensitive manufacturing processes. Emergency or standby-rated generators in these settings are generally limited to 200 hours of operation per year, with their average power output capped at 70% of the nameplate rating over a 24-hour period.

IEEE 446-1995 emphasizes the importance of cost-reliability analyses for industrial applications. These analyses help balance the high costs of production downtime against the capital investment required for reliable standby systems. Additionally, for facilities in flood-prone areas, the standard advises placing all power distribution equipment and generators above the 100-year flood plain. High-security facilities are even encouraged to consider higher levels, such as the 500-year or 1,000-year flood plain, to mitigate risks.

These tailored recommendations ensure that diverse industries can meet their specific operational demands, whether it's maintaining uninterrupted hospital services or ensuring the reliability of manufacturing processes.

Conclusion

Summary of Recommendations

IEEE 446-1995 provides a detailed framework for creating, managing, and maintaining standby power systems that ensure industrial and commercial facilities remain functional during utility outages. The standard covers critical areas like power source selection, fault protection, grounding, maintenance, and balancing cost with reliability. Chapter 10, in particular, lays out reliability objectives to help engineers perform cost-versus-reliability analyses, ensuring that investments in these systems are both practical and effective. These guidelines serve as the foundation for designing a dependable standby power system, ensuring continuous operations while making the most of your investment.

How Electrical Trader Can Help

To put IEEE 446-1995's recommendations into action, high-quality components are essential - like circuit breakers, transformers, and backup generators. Electrical Trader (https://electricaltrader.com) offers a wide range of both new and used electrical components tailored for standby power systems. Their inventory includes automatic transfer switches for seamless power transitions, uninterruptible power supplies for protecting sensitive equipment, and protective relays that enhance fault protection - all designed to meet the standards outlined in IEEE 446-1995.

Whether you're setting up a new system or upgrading an existing one, sourcing components from a reliable marketplace ensures your system complies with IEEE 446-1995 and aligns with US electrical codes.

FAQs

What advantages does a hybrid standby power system provide?

A hybrid standby power system combines multiple power sources to deliver reliable and flexible performance. By blending these sources, the system can smoothly manage power outages or equipment issues, reducing the risk of extended downtime.

On top of that, hybrid systems are designed to improve energy use by distributing loads efficiently across the available power sources. This makes them an excellent option for applications where maintaining a steady power supply is absolutely crucial.

What does IEEE 446-1995 recommend for ensuring safety and reliability in standby power systems?

IEEE 446-1995 outlines important practices to improve the safety and dependability of standby power systems. It focuses on several critical aspects, including safeguarding power sources and switching equipment during faults, establishing proper system grounding, and ensuring regular maintenance routines are in place.

These practices aim to reduce potential risks, maintain steady performance, and prolong the lifespan of emergency power systems. By adhering to these guidelines, operators can ensure reliable backup power for essential operations.

Why is regular maintenance important for standby power systems as outlined in IEEE 446-1995?

Keeping standby power systems in good shape is crucial to ensure they’re dependable and ready to kick in during power outages. According to IEEE 446-1995, regular upkeep tackles key areas like system protection, design integrity, and operational readiness.

Routine tasks like inspections, testing, and servicing help spot and fix potential problems before they escalate into major failures. This doesn’t just improve performance - it also helps your equipment last longer, so you’re not left in the dark when reliable power is critical.