Ultimate Guide to Medium Voltage Load Management

Share

Medium voltage systems (1 kV to 35 kV) are critical in power distribution, bridging high-voltage transmission and low-voltage systems used in homes and businesses. Load management in these systems focuses on redistributing electrical loads to prevent overloads, optimize performance, and protect infrastructure. This involves using specialized equipment like switchgear, transformers, and voltage regulators.

Key Takeaways:

- Load Management: Balances electricity demand by redistributing loads, reducing peaks, and preventing circuit overloads.

- Equipment: Includes switchgear, transformers, motor control centers, load banks, and intelligent monitoring tools.

- Safety and Reliability: Advanced systems use real-time monitoring and automation to improve efficiency and reduce risks.

- Strategies: Feeder reconfiguration, voltage control, and automated load shedding ensure stable and efficient operation.

From planning to maintenance, medium voltage systems require careful attention to ensure reliability and safety. The right equipment and strategies can help utilities and facilities manage loads effectively while extending the lifespan of critical components.

IBM: An Intelligent Load Management JumpStart System for Grid Operations

Core Components of Medium Voltage Systems

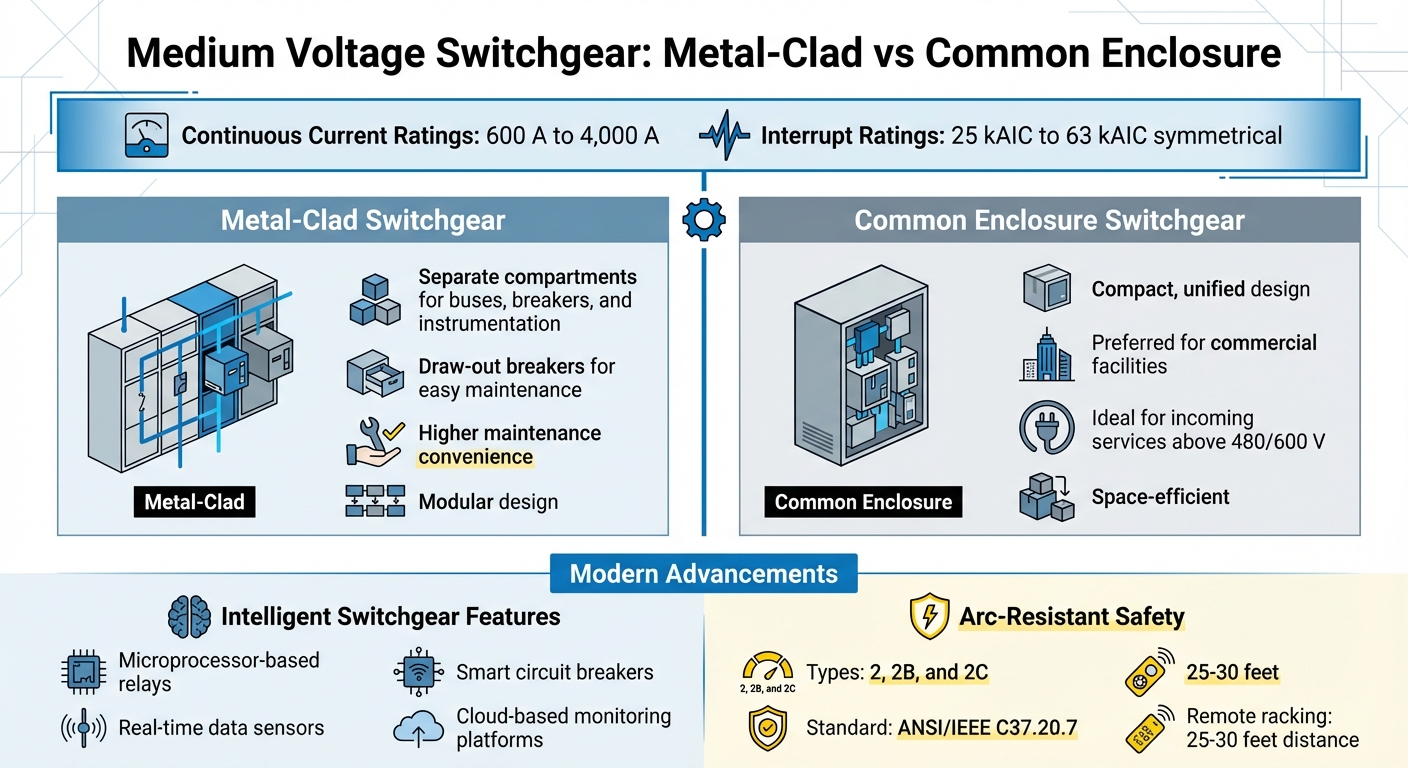

Medium Voltage Switchgear Types Comparison: Metal-Clad vs Common Enclosure

Medium Voltage Switchgear

Switchgear acts as the command center for medium voltage systems, containing circuit breakers, fuses, and switches within metal enclosures. These enclosures are designed to protect, control, and isolate electrical equipment, minimizing the impact of faults by isolating problem areas to limit outages. Modern switchgear typically supports continuous current ratings from 600 A to 4,000 A and interrupt ratings between 25 kAIC and 63 kAIC symmetrical.

There are two primary designs: metal-clad switchgear and common enclosure switchgear. Metal-clad designs have separate compartments for buses, breakers, and instrumentation, making maintenance more convenient with draw-out breakers. On the other hand, common enclosure designs are often preferred for commercial facilities with incoming services above 480/600 V due to their compact nature.

The evolution of intelligent switchgear has revolutionized load management. By integrating microprocessor-based relays, sensors, and smart circuit breakers, operators can now analyze real-time data through cloud-based platforms. For environments where safety is paramount, arc-resistant switchgear (Types 2, 2B, and 2C) is built to direct arc flash energy away from personnel, adhering to ANSI/IEEE C37.20.7 standards. Remote racking systems further improve safety, allowing operators to disconnect or test circuit breakers from a distance of 25 to 30 feet. These advancements ensure that modern medium voltage systems are safer, more efficient, and easier to manage.

Transformers and Voltage Control

Medium voltage transformers play a critical role in stepping down voltages from 5 kV to 35 kV for end-user applications. Equipped with integrated tap-changers and load-break switches, these transformers allow voltage adjustments without requiring the system to be de-energized. This functionality is crucial for maintaining balanced load distribution.

Vacuum Fault Interrupters (VFIs) simplify system design by combining overcurrent protection and load-break switching in a single unit. VFIs can even be integrated directly into transformers, reducing both the equipment footprint and the complexity of the overall setup.

Transformers have also seen significant advancements in monitoring capabilities. Built-in sensors now provide real-time data on voltage, energy, current, and temperature, enabling predictive diagnostics. This gives utility operators a clearer picture of grid performance. Safety has also improved with the use of alternative insulating fluids. While traditional mineral oil has a fire point of approximately 155°C (311°F), newer fluids like FR3 exceed 300°C (572°F), making them safer for indoor or high-traffic installations. Combined with robust monitoring systems, these features ensure transformers operate reliably under realistic load conditions, often verified using load banks.

Medium Voltage Load Banks

Load banks are essential for testing load management strategies under real-world conditions. One of the most challenging scenarios is cold load pickup, which occurs when a feeder is re-energized after being offline for 20 minutes or longer.

"Whenever a service has been interrupted to a distribution feeder for 20 minutes or more, it may be extremely difficult to re-energize the load without causing protective relays or fuses to operate... This is caused by magnetizing inrush currents to transformers, motor starting currents, and current to raise the temperature of lamps."

- Leslie Fernandez, Senior Project Engineer, JBA Consulting Engineers

During cold load pickup, transformer inrush currents can surge dramatically - up to 12 times the primary rated current for 0.1 seconds and as high as 25 times for 0.01 seconds. Testing equipment under these surge conditions is critical to ensure that protection settings are calibrated to prevent nuisance tripping. Accurate surge testing helps confirm that systems can handle sudden load shifts without unnecessary interruptions. Platforms like Electrical Trader connect industry professionals with the tools and equipment needed to design and maintain resilient medium voltage systems.

Strategies for Medium Voltage Load Management

Feeder Reconfiguration and Load Balancing

Balancing the load across medium voltage feeders is a practical way to prevent localized overloading and extend the lifespan of equipment. To do this effectively, it's crucial to understand load demand patterns. For instance, government buildings and schools generally see their peak usage between 8 a.m. and 6 p.m., while residential areas and street lighting demand spikes between 6 p.m. and 10 p.m. Combining these user types on the same feeder can help flatten the overall load profile, avoiding sharp peaks that strain the system.

A real-world example of this principle comes from a 2020 study on an 11 kV network in Egypt. In this case, two kiosks were transferred between feeders to balance the load. This adjustment reduced the evening load on Feeder B from 220 A to approximately 150–165 A, while Feeder A's load increased from 105 A. Both feeders were then operating within the recommended 80% capacity, which eased thermal stress on the transformers.

"LM relies only on the designer or service provider in re-distributing loads according to the load behavior studies (time, location, and type of user) without depending on the consumer in solving the phenomena of extreme fluctuations." - Energy Reports

By strategically redistributing loads, utilities can prevent frequent protection trips and mitigate the risk of overloads, as demonstrated in this case study.

Voltage and Reactive Power Control

Ensuring voltage stability in medium voltage networks involves a coordinated approach using capacitor banks, reactors, and On-Load Tap Changers (OLTCs). OLTCs are particularly useful because they can adjust voltage settings without taking the system offline. Additionally, distributed generation (DG) units, such as those powered by renewable energy, can provide immediate local voltage support by injecting reactive power. This coordination reduces active power losses and helps manage overvoltages in systems with a high penetration of renewables.

A modern approach to voltage control involves delaying OLTC activation to allow DG units to respond first. This reduces the wear on OLTCs and optimizes the use of reactive power. Some utilities also utilize the natural inductive properties of medium voltage loads to help mitigate overvoltages. These strategies not only stabilize voltage but also pave the way for more advanced automation in load management.

Load Shedding and Automation

Automated load management systems take a proactive approach to prevent overloads by continuously monitoring and redistributing loads across the network. Unlike traditional load shedding - which simply disconnects feeders during emergencies - these systems use relays and breakers to dynamically balance the load in real-time. They build on strategies like feeder reconfiguration and voltage control to provide a more responsive and efficient solution.

One example of this in action occurred in September 2025, when Hungarian utility ELMŰ-ÉMÁSZ collaborated with WM Systems to upgrade outdated medium-voltage switchgear for real-time monitoring and automation. Despite facing installation challenges, the project successfully enabled the utility to deploy automated load management strategies, significantly improving network reliability. By integrating measurement tools with circuit breakers, utilities can collect demand data at regular intervals and adjust feeder configurations dynamically, reducing the risk of failures during peak demand periods.

sbb-itb-501186b

Planning and Operations for MV Load Management

Load Forecasting and System Design

Planning for medium voltage (MV) load management starts with a solid grasp of how loads behave over time, across different locations, and based on user types. By aligning load profiles, you can smooth out demand peaks and reduce strain on equipment, ultimately improving system performance and reliability.

Early collaboration with utilities and mechanical engineers is critical. This step helps establish voltage ratings and motor load requirements. These inputs guide key decisions, such as selecting between radial, loop-primary, or primary selective system architectures. Additionally, performing essential calculations - like short-circuit analysis, arc flash energy assessments, load flow simulations, and motor starting analysis - ensures the system can handle both standard and unexpected conditions.

For instance, when low-voltage switchboards exceed 5,000–6,000 A, arc flash risks become more pronounced. In such cases, switching to medium voltage may be a safer and more cost-effective choice. In ring-main configurations, keeping feeder loads at 50% of their thermal capacity allows for a switchable reserve during outages, improving system flexibility.

This foundational system design supports the development of effective protection and control strategies, ensuring the system operates reliably under all conditions.

Protection and Control Schemes

Designing protection schemes involves selecting the right protective relays and ensuring they work together to isolate faults without disrupting the entire system. Common choices include IEEE relays like 50 (instantaneous overcurrent), 51 (time overcurrent), and 87 (differential protection). Ground fault relays should be configured to trip faults of 1,200 A or higher within a second.

Unlike low-voltage systems, medium voltage setups need a dependable DC control power source - usually 48 V or 120 V DC - to operate protective relays and circuit breakers. For balanced distribution systems, ground relays can be set to respond to as little as 25% of the load current. Protective current transformers (CTs), meanwhile, typically deliver about 5 amps or less during normal operation.

"The safety of the end user is of paramount importance and should be incorporated into every design."

- Taha Mohammed and Robert Magsipoc, Electrical Engineers, CDM Smith

To handle inrush currents during cold load pickup, protection settings must be carefully calibrated. For example, using extremely inverse relay curves can help avoid nuisance tripping when feeder lines are re-energized and experience high inrush currents.

Maintenance and Testing of MV Equipment

Routine maintenance, carried out according to IEC and IEEE standards, is essential for both safety and the long-term reliability of MV systems. Environmental factors like high humidity and temperature swings can damage insulation. To mitigate these risks, install controlled heaters with humidistats inside switchgear panels. Standby batteries should be tested regularly following IEEE 485 and IEEE 1115 guidelines to ensure they maintain adequate amp-hour capacity.

When testing protection systems, confirm that the relay’s tripping time, combined with the mechanical opening delay of the switching device, aligns with the rated short-circuit duration. These practices are crucial for maintaining system reliability.

To minimize downtime during maintenance, double-ended (main-tie-main) designs can allow servicing without shutting down the entire system. Safety can also be enhanced by using remote racking mechanisms or low-voltage mimic panels, enabling operators to control MV switchgear from outside the arc flash boundary. In areas with high pollution or near coastal regions, monitoring for partial discharge on busbars is vital. Airborne contaminants can lead to insulation tracking, which may eventually cause system failure.

| Protection Device | IEEE Number | Function |

|---|---|---|

| Undervoltage Relay | 27 | Detects low voltage conditions |

| Instantaneous Overcurrent | 50 | Provides immediate fault protection |

| AC Time Overcurrent | 51 | Offers delayed overcurrent protection |

| Frequency Relay | 81 | Monitors system frequency |

| Differential Protective Relay | 87 | Compares current in/out of a zone |

Conclusion

Managing medium voltage (MV) loads effectively requires a careful balance of safety, reliability, and cost-efficiency. The choice of MV equipment and system configurations significantly influences overall performance and safety outcomes. This framework forms the foundation for all MV load management efforts.

Provider-driven load management offers a way to sidestep the unpredictability of consumer behavior, delivering tangible improvements. Studies have shown that redistributing loads strategically can prevent equipment from overloading. From switchgear to transformers, every component discussed earlier plays a vital role in maintaining operational efficiency and safety.

Early planning is key. Decisions around voltage ratings, motor requirements, and system redundancies should be made upfront. Reliable control power for protective relays is critical to ensuring systems operate safely under any condition. Incorporating DC control systems, redundancy measures, and digital monitoring tools can further enhance reliability. While MV equipment involves higher initial costs compared to low-voltage alternatives, the savings on conduits and conductors, along with better efficiency for long-distance distribution, often make it the smarter choice for facilities handling loads above 5,000–6,000 amperes.

For professionals looking to implement these strategies, a wide array of MV components is available on specialized platforms. Explore Electrical Trader (https://electricaltrader.com) to source the components needed to design safe and efficient medium voltage systems.

FAQs

What are the benefits of using intelligent switchgear in medium voltage systems?

Intelligent switchgear takes medium voltage (MV) systems to the next level by blending traditional features with cutting-edge monitoring and automation tools. With the integration of intelligent electronic devices (IEDs), these systems can track essential parameters like voltage, current, and temperature in real-time. This real-time data helps operators spot potential problems early, enabling them to plan maintenance ahead of time, which minimizes unexpected downtime and boosts system reliability.

Another major advantage is remote operation. Operators can manage breakers, tweak protection settings, and execute load-shedding strategies without being on-site. This not only speeds up responses to disruptions but also enhances safety for field workers. Plus, when connected with other Industrial Internet of Things (IIoT) devices, intelligent switchgear contributes to smarter energy use and better coordination within today’s advanced power distribution networks.

How do medium voltage transformers enhance load management efficiency?

Medium voltage transformers are crucial for managing electrical loads effectively. They adjust electrical energy to the right voltage levels needed for efficient distribution, which helps cut down on energy losses during transmission, reduces heat buildup, and improves voltage stability throughout the system.

By streamlining energy flow, these transformers also allow systems to operate with fewer conductors and equipment, which can lower operational expenses and boost overall reliability. On top of that, they run more efficiently, staying cooler and reducing the overall cost of ownership. For those aiming to upgrade their systems, medium voltage transformers offer a smart path toward long-term energy efficiency.

How can overloads be prevented in medium voltage networks?

Preventing overloads in medium voltage (MV) networks involves a mix of smart load management and reliable overcurrent protection. By prioritizing non-essential loads, shedding them when necessary, or staggering the startup of large motors, you can keep the system stable and avoid sudden demand surges.

Equally important is ensuring proper overcurrent protection to shield equipment from damage. This means using devices like breakers and relays that are rated correctly for the system. For instance, switchgear with ratings between 600 A and 1,200 A is commonly used in 5–15 kV systems. These devices must be carefully coordinated with the overall system design and meet industry standards to reduce the chances of overload.

Working closely with your local utility and designing systems with adequate capacity also plays a key role in avoiding critical load thresholds. To support these efforts, Electrical Trader provides a wide range of MV components, including breakers, relays, and switchgear, designed to help implement these strategies effectively.