Low vs. Medium Voltage Switchgear: Key Differences

Share

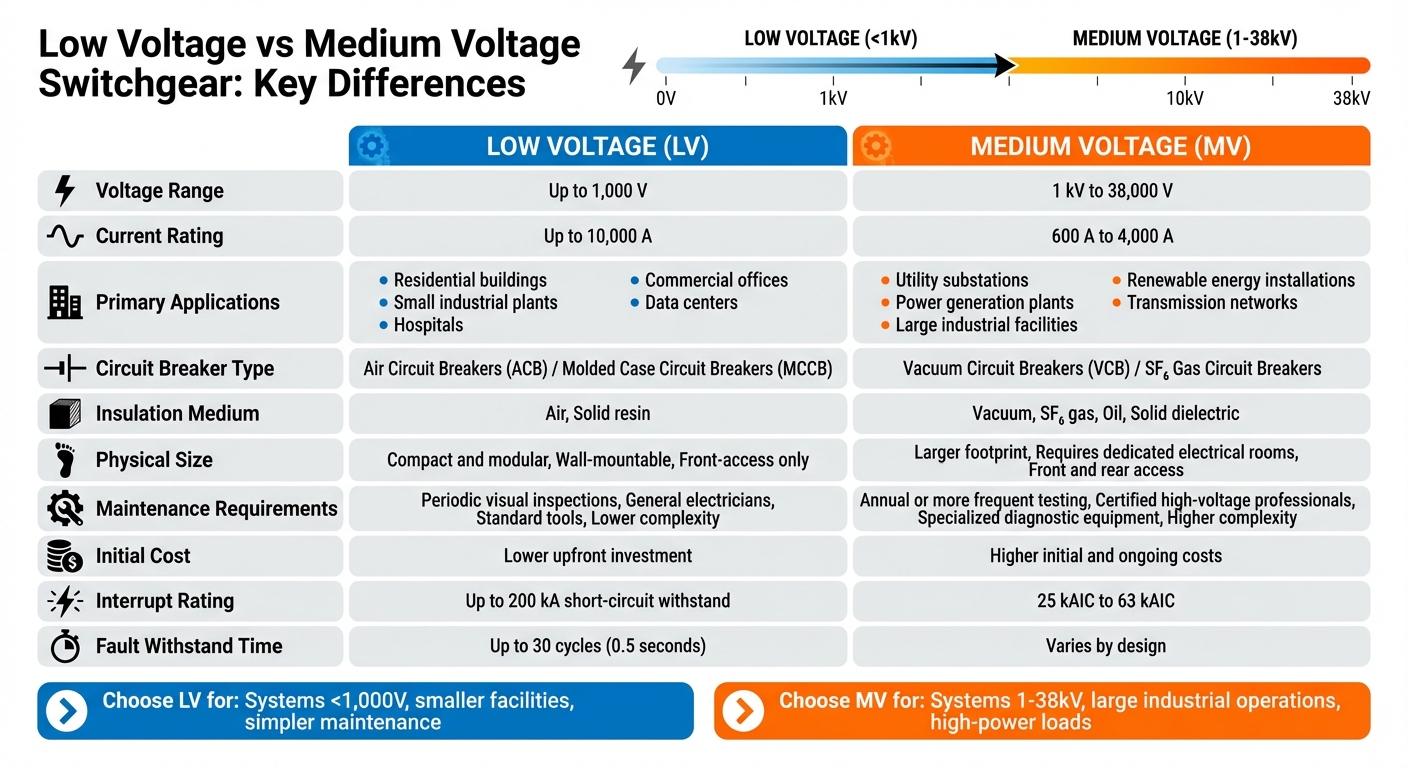

When choosing between low and medium voltage switchgear, the key difference lies in their voltage range and applications:

- Low Voltage (LV) Switchgear: Operates up to 1,000 volts and is ideal for residential, commercial, and smaller industrial facilities. It's compact, easier to maintain, and cost-effective. Commonly uses air insulation and air circuit breakers.

- Medium Voltage (MV) Switchgear: Handles 1,000 to 38,000 volts (up to 69,000 volts under IEEE standards) and is used in utilities, large industrial plants, and power generation. It requires advanced insulation (vacuum, SF6 gas, or oil) and specialized maintenance.

Quick Overview

- LV Switchgear: Best for smaller-scale setups with lower power needs, easier to install and maintain.

- MV Switchgear: Designed for high-power loads in large or critical operations, with more complex systems and higher costs.

Quick Comparison

| Feature | Low Voltage Switchgear | Medium Voltage Switchgear |

|---|---|---|

| Voltage Range | Up to 1,000 V | 1 kV to 38,000 V |

| Current Rating | Up to 10,000 A | 600 A to 4,000 A |

| Applications | Residential, commercial | Utilities, industrial plants |

| Insulation Medium | Air, solid resin | Vacuum, SF6 gas, oil |

| Maintenance | Simple, periodic checks | Requires specialized expertise |

| Cost | Lower upfront cost | Higher initial and ongoing costs |

Selecting the right switchgear depends on your system's voltage, power needs, space, and maintenance capacity. LV systems suit smaller, simpler setups, while MV systems are built for heavy-duty operations.

Low Voltage vs Medium Voltage Switchgear Comparison Chart

Low Voltage Switchgear : A Beginner’s Guide | TheElectricalGuy

What is Low Voltage Switchgear?

Low voltage switchgear is a metal-enclosed system designed to house circuit breakers, fuses, and switches, providing protection and isolation for electrical equipment operating at voltages up to 1,000V. As Erik Hurd, Senior PSEC Engineer at Eaton, puts it:

Low-voltage switchgear plays a central role within power distribution systems.

Typically installed on the secondary side of transformers, this equipment distributes power to motor control centers, switchboards, and branch circuits, ensuring efficient and safe operation.

The design of low voltage switchgear stands out due to its three separate compartments: the breaker compartment (holding up to four vertically stacked breakers), the bus compartment (housing silver- or tin-plated copper bus bars), and the cable compartment (used for line and load terminations). This compartmentalized structure differentiates it from simpler switchboards. These units can handle continuous current ratings of up to 6,000 amps, with some configurations under ANSI/NEMA standards reaching 10,000 amps. They also feature short-circuit withstand ratings as high as 200kA. This precise engineering ensures dependable power distribution, which is crucial for maintaining system integrity.

Features of Low Voltage Switchgear

Low voltage switchgear primarily uses air circuit breakers (ACBs) with open-air contacts to interrupt fault currents, unlike medium voltage systems that rely on vacuum or SF6 gas interrupters. It has a standard insulation level of 2.2kV and can withstand faults for up to 30 cycles (0.5 seconds), a significant improvement over the typical 3-cycle rating of switchboards. This extended fault tolerance allows for selective coordination, ensuring that only the breaker closest to the fault trips, minimizing the risk of widespread outages.

A key feature is its "draw-out" design, which allows circuit breakers to be removed for maintenance without shutting down the entire system. Modern units often include intelligent electronic devices (IEDs), smart sensors, and microprocessor-based relays, enabling advanced cloud-based analytics for predictive maintenance. Safety is further enhanced with features like arc-quenching systems and Zone Selective Interlocking (ZSI), which help reduce the energy released during electrical faults. These innovations make low voltage switchgear a versatile and reliable choice for a wide range of applications.

Where Low Voltage Switchgear is Used

Low voltage switchgear is widely used across various industries and facilities, including commercial buildings, data centers, healthcare facilities, small industrial plants, manufacturing sites, mining operations, oil and gas facilities, automotive plants, pharmaceutical production, water treatment plants, waste disposal facilities, and transformer stations. Its 30-cycle short-time fault withstand rating is especially valuable in critical environments like hospitals, where selective coordination ensures that a single fault doesn’t disrupt essential systems or entire sections of the facility.

What is Medium Voltage Switchgear?

Medium voltage switchgear refers to metal-enclosed systems designed to protect and manage equipment operating between 1 kV and 38 kV (or up to 69 kV, as defined by ANSI/IEEE). These systems act as a crucial link between high-voltage transmission lines and low-voltage distribution networks, making them indispensable for utility grids and large industrial setups. According to Eaton:

"Switchgear is commonly found throughout electric utility transmission and distribution systems as well as in medium to large sized commercial or industrial facilities."

This underscores the importance of medium voltage switchgear as a key intermediary in electrical systems.

To handle fault currents, medium voltage switchgear relies on technologies like vacuum circuit breakers (VCBs) or SF₆ gas-insulated switchgear (GIS). Unlike low-voltage designs, medium voltage systems use compact, high-dielectric insulation methods, such as SF₆ gas, mineral oil, biodegradable fluids, or solid materials, to prevent arc faults. These advanced insulation techniques allow the equipment to manage higher voltage faults within a smaller footprint.

Built for durability, medium voltage switchgear typically offers continuous current ratings ranging from 600 A to 4,000 A and interrupt ratings between 25 kAIC and 63 kAIC. Metal-clad designs further enhance safety and ease of maintenance by compartmentalizing areas for incoming and outgoing buses, instrumentation, and circuit breakers. Arc-resistant configurations, tested to ANSI/IEEE C37.20.7 standards, ensure that fault energy is safely contained.

Features of Medium Voltage Switchgear

Medium voltage switchgear stands out for its advanced interruption and safety features. A key component is the vacuum interrupter, which extinguishes electrical arcs within sealed vacuum bottles. This technology enables the equipment to manage higher voltage faults while requiring significantly less space compared to air circuit breaker systems. Installation and maintenance typically require access to both the front and rear, although front-access-only designs are available for tighter spaces.

Modern systems incorporate intelligent electronic devices (IEDs), such as microprocessor-based relays and smart sensors, which provide real-time diagnostics and remote monitoring capabilities. Standard components include protective relays, disconnect switches, and earthing switches. Additionally, the equipment is available in various configurations - metal-clad, metal-enclosed, gas-insulated, and pad-mounted - making it adaptable to different environments.

Where Medium Voltage Switchgear is Used

Medium voltage switchgear is essential in settings where electrical service exceeds 480 V or 600 V. Common voltage classes include:

- 4.16 kV and 4.8 kV: Used for industrial motors and small substations.

- 12.47 kV to 14.4 kV: Common in utility distribution systems and large industrial facilities.

- 24.9 kV: Found in utility distribution networks.

- 34.5 kV: Typically used for large-scale power generation and transmission.

This equipment is widely utilized in electric utility transmission and distribution systems, power generation plants, large manufacturing facilities, oil and gas operations, rail systems, and renewable energy installations. For example, solar energy plants depend on medium voltage switchgear to manage electricity flow from generation units to the power grid. Unlike low-voltage systems, which are simpler to operate, medium voltage switchgear requires trained and qualified personnel due to the higher voltages and more complex protection mechanisms involved.

Main Differences Between Low and Medium Voltage Switchgear

Building on earlier descriptions, these technical differences directly impact performance, installation choices, safety, and cost considerations.

Voltage Range and Power Capacity

Low voltage equipment operates at 1,000 volts or below, while medium voltage covers a range from 1,000 to 38,000 volts. As NOJA Power explains:

In electrical engineering, a general rule is that equipment operating at 1,000 volts or less is considered low voltage. Equipment from 1,000 volts up to 38,000 volts is considered medium voltage.

Low-voltage (LV) switchgear is designed to handle higher current capacities. For example, a 4 MVA transformer used with a 400V LV switchboard can produce up to 6,300 amps and withstand current harmonics of 100 kA. In contrast, medium-voltage (MV) switchgear typically operates with current ratings between 630 and 5,000 amps, with short-circuit breaking currents ranging from 16 kA to 50 kA.

These differences reflect their intended applications. According to CTI Electric:

Low-voltage systems are well-suited for applications that require moderate power levels... Medium-voltage systems are designed to handle high power loads.

LV systems are commonly used in residential, commercial, and light industrial environments for tasks like lighting and powering small motors. On the other hand, MV systems are essential for utility substations, large industrial facilities, data centers, and renewable energy installations. Beyond power capacity, design differences also play a critical role in their applications.

Design, Size, and Enclosure

Low voltage switchgear is typically compact, modular, and space-efficient. It often features front-accessible configurations, which can be wall-mounted to save floor space. These units are divided into three compartments for breakers, busbars, and cable connections.

Medium voltage switchgear, however, requires more space and dual-access for maintenance. While some specialized designs allow front-only access for tight spaces, most MV systems demand both front and rear access. The physical size of MV switchgear largely depends on the insulation medium. Air-insulated units require larger air gaps for proper dielectric strength, whereas SF₆ gas-insulated designs are much more compact.

LV switchgear is user-friendly and designed for operation by general personnel. In contrast, MV systems require specialized expertise due to their complexity and safety features. MV designs often include protective interlocks and advanced arc-resistant features that redirect fault energy away from personnel. Metal-clad MV configurations provide an added layer of safety by enclosing all components in separate metal compartments.

| Feature | Low Voltage Switchgear | Medium Voltage Switchgear |

|---|---|---|

| Voltage Range | Up to 1,000 V | 1 kV to 38,000 V |

| Physical Size | Compact and modular | Larger footprint |

| Compartments | 3 sections (breaker, busbar, cable) | Varies; metal-clad uses separate barriers |

| Access Requirements | Front-only; wall-mountable | Front and rear; front-only in specific cases |

| Insulation Medium | Primarily air | Air, SF₆ gas, oil, or solid dielectric |

| Common Enclosures | Metal-enclosed | Metal-clad, metal-enclosed, pad-mounted, vault |

Components and Insulation

The components and insulation materials used in LV and MV switchgear further distinguish the two. Low voltage systems commonly use air circuit breakers (ACBs) or molded case circuit breakers (MCCBs). As Eaton explains:

Low-voltage circuit breakers interrupt short-circuit and overload faults via main contacts that part in open air. Consequently, such circuit breakers are also known as air circuit breakers (ACB).

Medium voltage systems, on the other hand, use vacuum circuit breakers (VCBs) or SF₆ gas circuit breakers. These devices extinguish arcs within sealed vacuum bottles or gas-filled chambers. LV systems typically include integral trip units for protection, while MV systems rely on external, microprocessor-based relays for advanced protection schemes and remote monitoring.

Insulation also varies significantly. LV systems primarily use air as an insulator, occasionally supplemented by solid resin. MV systems, however, employ a range of materials, including air, SF₆ gas, vacuum, oil, or solid dielectric. As Eaton points out:

While air is the most common insulator, gas and fluid insulation provide higher dielectric strength allowing the switchgear structures to be smaller.

This use of advanced insulation materials allows gas-insulated MV switchgear to handle higher voltages while maintaining a compact footprint.

| Component | Low Voltage Switchgear | Medium Voltage Switchgear |

|---|---|---|

| Primary Breaker Type | Air Circuit Breaker (ACB) | Vacuum Circuit Breaker (VCB) |

| Arc Quenching | In open air | In sealed vacuum or gas chambers |

| Protection Device | Integral trip units | Microprocessor-based relays |

| Insulation Medium | Air; some solid resin | Air, SF₆ gas, vacuum, oil, solid dielectric |

| Continuous Current Rating | Up to 10,000 A | 600 A to 4,000 A |

| Interrupt Rating | Up to 200 kA short-circuit withstand | 25 kAIC to 63 kAIC symmetrical |

sbb-itb-501186b

Cost and Maintenance Considerations

Initial Purchase Costs

Low voltage (LV) switchgear tends to be easier on the budget thanks to its simpler design, reliance on cost-effective air for insulation, and modular construction. On the other hand, medium voltage (MV) equipment comes with a heftier price tag. This higher cost is tied to its ability to handle greater energy levels and its adherence to stricter safety standards. If you’re considering gas-insulated systems, expect to pay more than for air-insulated designs - though their compact footprint can offset structural expenses.

As Tonyhoo puts it:

Typically, MV switchgear is more expensive than LV switchgear because of the higher voltage levels and additional safety features required.

For smaller-scale setups, like residential areas or small offices, LV systems are a cost-effective choice. But when power needs climb above 250 kW or involve long-distance transmission, MV systems are the way to go. Keep in mind that hazardous or offshore environments can drive up costs significantly.

These differences in upfront costs also affect how you'll approach long-term maintenance.

Maintenance Requirements

The cost gap between LV and MV systems doesn’t stop at the initial investment - it extends into maintenance. LV systems are relatively simple to maintain, often requiring just periodic visual inspections. General electricians with standard tools can handle routine upkeep with ease.

MV systems, however, are a different story. They demand more frequent inspections and specialized expertise. Tonyhoo explains:

MV switchgear requires more frequent testing and inspection due to the critical nature of high voltage systems.

In practical terms, this means MV switchgear needs certified high-voltage professionals and specialized diagnostic tools. Annual - or sometimes even more frequent - testing is necessary to ensure safety and reliability.

| Requirement | Low Voltage (LV) | Medium Voltage (MV) |

|---|---|---|

| Inspection Frequency | Periodic visual checks | Annual or more frequent testing |

| Required Personnel | General electricians or staff | Certified high-voltage professionals |

| Tools Required | Standard electrical tools | Specialized diagnostic equipment |

| Complexity | Straightforward and modular | Complex with robust safety protocols |

| Operating Expenses | Lower long-term costs | Higher ongoing costs |

When choosing switchgear, it’s essential to weigh both initial costs and maintenance needs to ensure you’re meeting operational demands without overspending.

How to Choose Between Low and Medium Voltage Switchgear

The first step in deciding between low voltage (LV) and medium voltage (MV) switchgear is to determine your system's operating voltage. If your facility runs on less than 1,000V - typically around 400V - then LV switchgear is what you need. On the other hand, systems operating between 1kV and 36kV require MV equipment.

Next, consider your facility's power load. LV systems are a good fit for residential buildings, commercial offices, and smaller manufacturing setups. However, if you're dealing with power generation facilities, transmission networks, or large industrial operations, MV switchgear is the better choice. Be sure to match the switchgear's capacity to your specific power needs, as outlined in earlier discussions.

Space availability and future growth plans are also critical factors. LV switchgear is modular, making it easier to expand or modify when your power demands increase. In contrast, MV equipment typically requires dedicated electrical rooms with both front and rear access, which can be a consideration if space is limited.

For facilities where continuous operation is essential - like hospitals, data centers, or manufacturing lines - selective coordination is a key feature to look for. LV switchgear with power circuit breakers can provide this functionality by isolating faults to the nearest breaker, ensuring minimal disruption.

Finally, think about the expertise of your personnel. LV switchgear is generally safer and more practical for staff without specialized training. MV systems, however, require certified high-voltage professionals and specialized diagnostic tools. Maintenance needs also differ: LV systems usually need periodic visual inspections, while MV equipment requires more frequent and detailed testing, often on an annual basis.

Conclusion

When choosing switchgear, match the voltage rating to your system's needs: low-voltage (LV) switchgear is suitable for systems up to 1,000V, while medium-voltage (MV) switchgear handles systems ranging from 1 kV to 35 kV. LV switchgear is commonly found in residential buildings, commercial offices, hospitals, and data centers, where continuous current can reach up to 10,000A. On the other hand, MV switchgear is critical for utilities, power generation facilities, and large industrial plants.

Key differences lie in design and maintenance: LV systems typically use air or molded case circuit breakers with air or solid insulation, making maintenance relatively straightforward. MV equipment, however, relies on vacuum or SF₆ gas-insulated breakers with interrupt ratings between 25 kAIC and 63 kAIC, requiring specialized expertise for proper upkeep.

Cost is another factor to consider. MV switchgear involves higher initial and installation expenses due to its complex insulation and advanced safety features. Meanwhile, LV systems are more budget-friendly, offering modular designs that simplify future expansions. These distinctions in cost and maintenance play a significant role in determining the best fit for your application.

For commercial and light industrial settings, LV switchgear is often the ideal choice. MV switchgear, with its robust design, is indispensable for heavy-duty power distribution. Maintenance needs are another consideration: LV systems demand minimal inspections, while MV systems require regular expert oversight. Align these factors with your operational budget to make an informed decision.

Finally, for critical operations, it's worth noting that LV breakers are designed to withstand faults for up to 30 cycles, ensuring selective coordination and minimizing disruptions.

FAQs

What safety factors should you consider when choosing low or medium voltage switchgear?

When choosing switchgear, safety must always come first. For low-voltage (LV) switchgear, which operates up to 600 V in the U.S., it's crucial to focus on proper grounding, dependable insulation, and following lock-out/tag-out procedures during maintenance. Additionally, using personal protective equipment (PPE) - like insulated gloves and safety glasses - and participating in regular safety training can significantly reduce risks.

For medium-voltage (MV) switchgear, operating between 600 V and 35 kV, the stakes are higher due to increased fault currents and arc-flash hazards. To address these risks, MV systems often include features like arc-flash protection, reinforced enclosures, interlocks that prevent access while the equipment is live, and remote operation capabilities. Adhering to safety standards such as IEEE C37, NEC 490, and OSHA 1910.269, along with routine testing and maintenance, is essential to ensure both safety and reliability.

In essence, while LV systems focus on basic protections like grounding and PPE, MV systems demand more advanced measures to safely manage higher energy levels.

What are the main differences in maintenance requirements for low-voltage and medium-voltage switchgear?

The maintenance needs of low-voltage (LV) and medium-voltage (MV) switchgear vary significantly, mainly due to differences in safety requirements and complexity.

Medium-voltage switchgear, operating above 1 kV, demands enhanced safety features, such as protective interlocks and sealed panels, to guard against high-energy arcs. Maintenance for this type of equipment often involves specialized tools, detailed procedures, and strict access controls to ensure the safety of technicians working with higher voltage levels.

On the other hand, low-voltage switchgear (up to 1 kV) is generally smaller and easier to work with. Routine maintenance tasks like inspections, cleaning, and replacing components can typically be completed with minimal downtime. Additionally, the lower voltage and fault energy levels reduce the need for advanced protective gear during servicing.

What should I consider when choosing between low and medium voltage switchgear?

When choosing between low-voltage (LV) and medium-voltage (MV) switchgear, it’s important to weigh a few key factors:

- Voltage and application: LV switchgear, rated for up to 1 kV (commonly 400–480 V in the U.S.), is best suited for residential, commercial, or smaller industrial setups. On the other hand, MV switchgear, designed for voltages ranging from 1 kV to 36 kV, is ideal for larger facilities like factories, data centers, or systems spread across a campus.

- Size and cost: LV switchgear is smaller and generally more affordable to install and maintain. MV switchgear, while larger and more expensive, offers the capacity to handle higher power demands and is a solid choice for facilities planning for growth or expansion.

- Safety and fault protection: MV switchgear typically comes with advanced safety measures, such as arc-resistant designs and higher fault-current ratings, making it a better choice for operations with significant electrical loads. LV switchgear, though simpler, adheres to key safety standards like NFPA 70 (NEC).

By assessing your facility’s current and future power requirements, safety considerations, and available space, you can decide which switchgear type aligns with your needs. Electrical Trader provides a broad range of both LV and MV switchgear to help meet your specific requirements.