Dry-Type Transformers: Fire Safety Features

Share

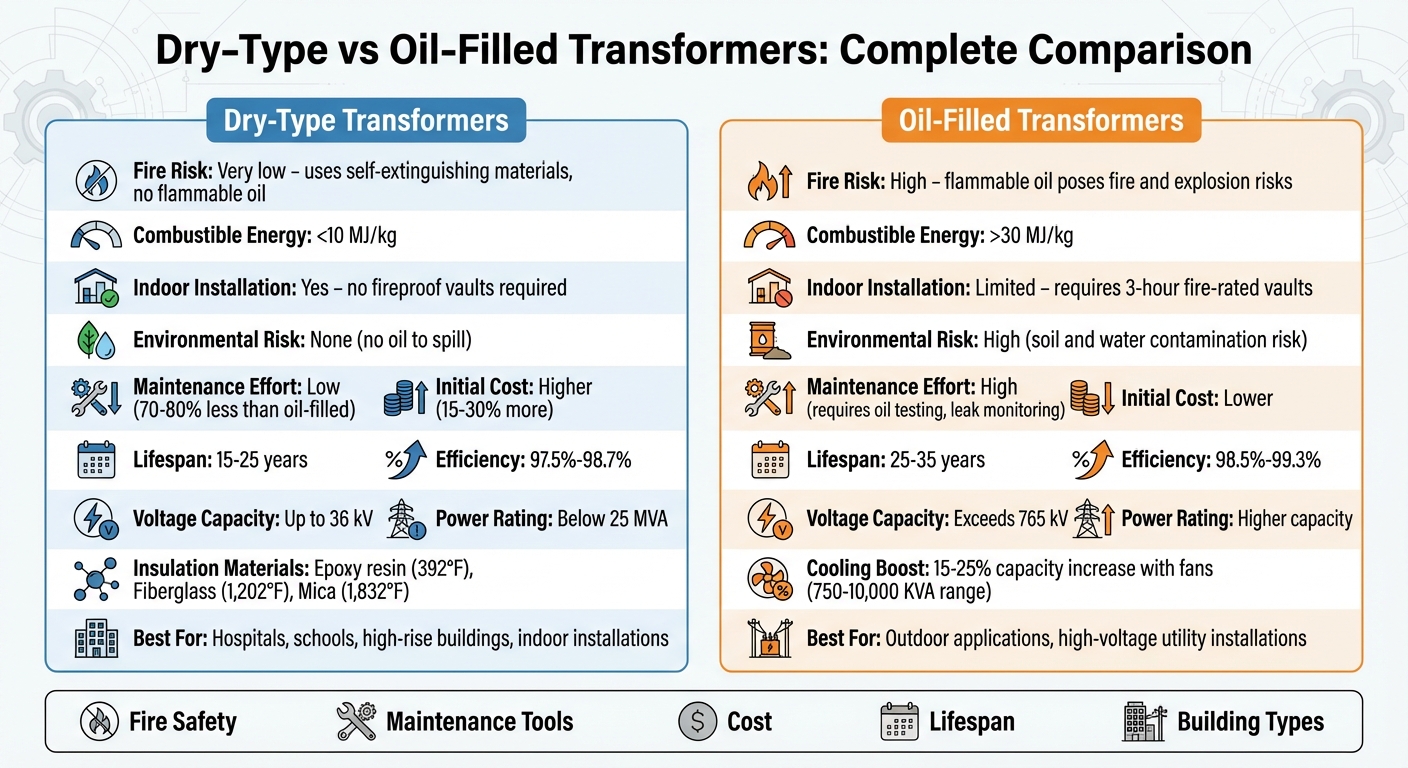

Dry-type transformers are a safer alternative to oil-filled transformers, especially in environments where fire risks must be minimized. These transformers use air and solid insulation materials like epoxy resin instead of flammable oil, significantly reducing the chance of fires and explosions. They are ideal for indoor installations, such as hospitals, schools, and high-rise buildings, due to their low fire risk and minimal maintenance needs. However, they tend to have a higher upfront cost and a shorter lifespan compared to oil-filled models.

Key Highlights:

- Fire Safety: Dry-type transformers eliminate the use of flammable oil, reducing fire risks.

- Installation: Suitable for indoor use without requiring fireproof vaults.

- Maintenance: Requires less upkeep than oil-filled transformers.

- Lifespan: Typically lasts 15–25 years, compared to 25–35 years for oil-filled units.

- Cost: Higher initial cost but lower long-term maintenance expenses.

Quick Comparison

| Feature | Dry-Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Fire Risk | Low (no oil) | High (flammable oil) |

| Indoor Installation | Yes, no fireproof vaults | Limited, requires vaults |

| Maintenance Effort | Low | High |

| Lifespan | 15–25 years | 25–35 years |

| Initial Cost | Higher | Lower |

| Voltage Capacity | Up to 36 kV | Exceeds 765 kV |

Dry-type transformers are a practical choice for fire-sensitive areas, while oil-filled transformers are better suited for high-voltage, outdoor applications. Each option has its trade-offs, but safety and reduced fire risks make dry-type transformers the preferred choice for indoor installations.

Dry-Type vs Oil-Filled Transformers: Fire Safety and Performance Comparison

1. Dry-Type Transformers

Fire Risk

Dry-type transformers address a critical safety concern found in traditional units: the risk of fire from flammable liquid dielectrics. Unlike oil-filled transformers, these units don’t rely on mineral oil or synthetic fluids, eliminating the chance of leaks, spills, or oil vapor explosions during electrical faults. Instead, they use solid insulation materials, such as epoxy resin, which stop burning as soon as the heat source is removed. This design choice significantly reduces fire hazards. For perspective, cast-resin dry-type transformers have a combustible energy of less than 10 MJ/kg, compared to over 30 MJ/kg in oil-filled models. This reduced fire risk also contributes to improved insulation performance and lower smoke emissions, which are explored further below.

Insulation Materials

The insulation in dry-type transformers is built to withstand extreme thermal conditions. Materials like epoxy resin can handle temperatures up to 392°F (200°C), fiberglass up to 1,202°F (650°C), and mica insulators up to 1,832°F (1,000°C). These materials are categorized into thermal classes - Class F (155°C), Class H (180°C), and Class 220 - where higher classes indicate better resistance to heat. Cast Resin Transformers (CRT) take this a step further by encapsulating windings in resin, protecting them from moisture and dust, which helps prevent partial discharges that could lead to electrical arcs or fires. Despite these robust features, extreme conditions can still lead to minor smoke emissions, as discussed next.

Smoke Emissions

Even though dry-type transformers are safer overall, their solid insulation can break down under extreme overloads. In such cases, materials like epoxy or varnished cellulose may emit smoke or contribute to arc flashes. However, the risks remain far lower than the catastrophic failures often associated with oil-filled transformers. To enhance safety, modern units are equipped with features like thermal sensors in the windings, smoke detectors, and arc-flash light sensors. These systems can detect abnormal conditions and shut the transformer down immediately, minimizing potential damage.

Cooling Methods

Proper cooling is essential to prevent heat buildup, which can damage insulation and increase fire risks. Dry-type transformers typically use Natural Air Cooling (AA), which relies on convection, or Forced Air Cooling (FA), which uses fans for higher-capacity units. Many modern systems include temperature sensors that monitor heat in real-time, triggering alarms or automatic shutdowns if temperatures exceed safe levels. Adequate airflow is crucial, and screened enclosures help limit the spread of flames. Cooling and ventilation components are often made of non-combustible materials like stainless steel or aluminum to further reduce fire hazards.

Maintenance Requirements

Regular maintenance is key to keeping dry-type transformers safe and reliable. Dust can build up and restrict airflow, increasing fire risks, so periodic vacuuming is crucial. Infrared thermal scans can identify hotspots in connections or windings before they lead to insulation failure. Placement also matters - ensuring proper clearance, ventilation, and installation in fire-rated rooms (e.g., those with a 1-hour fire rating) adds an extra layer of safety. With good maintenance and thermal management, these transformers typically last 20 to 30 years or even longer.

sbb-itb-501186b

2. Oil-Filled Transformers

Fire Risk

Oil-filled transformers rely on mineral oil for both insulation and cooling, which introduces a serious fire hazard. Unlike dry-type transformers that avoid flammable liquids altogether, oil-filled models demand comprehensive fire safety measures. Brian O'Connor, Technical Services Engineer at NFPA, highlights the potential dangers:

When a transformer fails it can lead to an intense fire and violent explosion... Transformers can hold anywhere between a few gallons to thousands of gallons.

To minimize risks, these transformers are usually installed outdoors or housed in specially designed indoor vaults with containment pits.

Insulation Materials

Oil-filled transformers combine mineral oil with solid insulating materials like cellulose paper and pressboard. This setup allows them to handle extremely high voltages - sometimes exceeding 765 kV - but also makes them inherently flammable. Some operators have started using alternative fluids, such as natural esters or synthetic options, which have higher fire points (above 300°C or 572°F). However, even these alternatives require secondary containment systems. The insulation materials not only enable high performance but also contribute to the severity of smoke and emissions during a fire.

Smoke Emissions

When an oil fire occurs, it produces intense flames and dense smoke, making it exceptionally difficult to extinguish. Taishan Transformer explains:

When an oil fire occurs, it can be very challenging to extinguish because of the oil's high flammability and continued heat generation.

To combat these fires, water spray systems are often employed, needing to discharge approximately 0.25 gpm/ft² onto the transformer's surface. Additionally, oil leaks pose environmental risks, potentially contaminating soil and water. Dry-type transformers, in contrast, use self-extinguishing resins that produce minimal smoke and eliminate these contamination concerns.

Cooling Methods

Oil-filled transformers excel at heat dissipation. The circulating oil absorbs heat from the core and windings and transfers it to radiators or cooling fins, enabling these transformers to manage higher voltages and larger power capacities than dry-type models. For units in the 750–10,000 KVA range, fan-assisted cooling can boost capacity by 15%–25%. While this efficient cooling system ensures safe operating temperatures and enhances performance, it also requires careful monitoring due to the flammability of the cooling medium. Robust safety protocols and regular maintenance are essential to mitigate fire risks.

Maintenance Requirements

Proper maintenance is a cornerstone of safe operation for oil-filled transformers. Key tasks include regular oil sampling, dissolved gas analysis, and monitoring for leaks. Testing for dielectric strength (per ASTM D-877), moisture levels, and flash/fire points ensures the oil remains functional. For indoor installations, NEC guidelines typically mandate a 3-hour fire-rated vault for standard mineral oil transformers.

Although these units demand 70%–80% more maintenance than dry-type transformers, they compensate with a longer lifespan, lasting 25 to 35 years - about a decade more than their dry-type counterparts. For those buying or selling used oil-filled transformers on platforms like Electrical Trader (https://electricaltrader.com), understanding these maintenance needs is essential. While the durability of oil-filled transformers is a clear advantage, their higher maintenance demands and fire risks make dry-type alternatives an appealing option for many applications.

Dry Type Transformer safety | Safety of Transformer | Transformer safety device

Pros and Cons

Dry-type and oil-filled transformers each come with their own set of benefits and drawbacks. Choosing the right one depends on factors like your application needs, budget, and how much risk you’re willing to take on.

Dry-type transformers are designed to avoid the hazards associated with flammable liquids. This makes them a great fit for indoor spaces where fire safety is a top priority - think hospitals, schools, or high-rise buildings. They also require far less maintenance and eliminate the chance of contamination. That said, these units tend to cost 15% to 30% more upfront, and their lifespan is shorter, typically ranging from 15 to 25 years. Their efficiency falls between 97.5% and 98.7%, and they’re generally limited to voltage levels up to 36 kV and power ratings below 25 MVA.

On the other hand, oil-filled transformers excel in heat dissipation and boast slightly higher efficiency, usually between 98.5% and 99.3%. They can handle much higher voltages - exceeding 765 kV - and larger power capacities. With a longer operational life of 25 to 35 years and a lower upfront cost, they’re often the go-to choice for large-scale utility applications. However, the flammable oil they use introduces significant fire and explosion risks. Indoor installations require costly fire-rated vaults, containment systems, and suppression systems to mitigate these hazards. Over a period of 15–20 years, maintenance costs for oil-filled units can be 2–4 times higher than those for dry-type transformers.

Here’s a quick side-by-side comparison:

| Feature | Dry-Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Fire Risk | Very low; uses self-extinguishing materials | High; flammable oil poses fire and explosion risks |

| Indoor Installation | Ideal; no special vaults required | Limited; requires fireproof vaults |

| Environmental Risk | None (no oil to spill) | High (risk of soil and water contamination) |

| Maintenance Effort | Low (70–80% less than oil-filled) | High (requires oil testing and leak monitoring) |

| Initial Cost | Higher | Lower |

| Lifespan | 15–25 years | 25–35 years |

| Efficiency | 97.5%–98.7% | 98.5%–99.3% |

| Voltage Capacity | Up to 36 kV | Exceeds 765 kV |

This breakdown provides a clear picture for anyone looking to make informed decisions in the electrical equipment market. Platforms like Electrical Trader (https://electricaltrader.com) can help buyers and sellers navigate these options. Dry-type transformers stand out for their fire safety and low maintenance, making them ideal for indoor commercial spaces. Meanwhile, oil-filled transformers shine in outdoor, high-voltage applications where their durability and efficiency offset the need for additional safety measures.

Conclusion

When fire safety is a priority, dry-type transformers stand out as a safer alternative to oil-filled units. By eliminating flammable liquids, they remove the primary risk factor for transformer fires and explosions. Their solid insulation materials - like epoxy resin and fiberglass - are designed to resist flames and limit fire spread effectively.

Industry experts emphasize the reliability of these transformers in fire-sensitive settings:

"Dry-type transformers are more likely to meet stringent safety standards in environments where fire risks need to be minimized, such as high-rise buildings, underground tunnels, and mining operations." - Taishan Transformer

Built for tough conditions, dry-type transformers handle extreme temperatures without degrading. Their fiberglass components remain stable even under high heat, while the absence of explosive oil vapors ensures safer operation during faults. This combination of thermal stability and fire resistance makes them a dependable choice for critical installations.

For spaces like hospitals, schools, and high-rise buildings, where fire safety is essential, dry-type transformers provide a practical solution. They can be installed indoors without requiring fireproof vaults or suppression systems. This not only lowers installation costs but also complies with strict building codes, such as NFPA 70, which aim to minimize flammable materials in high-occupancy areas.

Although their upfront cost is typically 15% to 30% higher than oil-filled alternatives, the long-term benefits are clear. Reduced maintenance and enhanced safety for both people and property make these transformers a worthwhile investment. For projects demanding top-tier fire safety, Electrical Trader (https://electricaltrader.com) offers a selection of new and used dry-type transformers tailored to meet your needs.

FAQs

What fire safety benefits do dry-type transformers offer compared to oil-filled transformers?

Dry-type transformers stand out for their enhanced fire safety features. Unlike their oil-filled counterparts, they don't rely on flammable liquids for insulation or cooling. Instead, they use air or other non-combustible materials, which significantly lowers the risk of fires or explosions.

These transformers are especially ideal for indoor setups or areas with stringent safety standards. By reducing fire-related risks and requiring less fire prevention maintenance, they offer a safer and more dependable option for various applications.

What makes dry-type transformers a safer and more reliable choice despite their higher upfront cost?

Dry-type transformers are a popular choice thanks to their strong safety features and minimal upkeep requirements, even if their upfront cost tends to be higher. Unlike oil-filled transformers, they don’t rely on flammable liquids, which greatly lowers the fire risk. This makes them particularly suited for indoor setups and locations with stringent safety standards.

On top of that, dry-type transformers are better for the environment and need less maintenance over their lifespan, which can lead to cost savings in the long run. Their robust construction and ability to perform well under tough conditions make them a dependable option for a wide range of uses.

What are the maintenance differences between dry-type transformers and oil-filled transformers?

Dry-type transformers tend to need less upkeep than oil-filled transformers because they rely on solid insulation materials like epoxy or resin instead of liquid insulation like mineral oil. This design removes the need for regular checks related to leaks, oil quality, or contamination, making them a more hassle-free choice for many uses.

On top of that, these transformers are often built to withstand environmental challenges, which cuts down on the need for frequent inspections or repairs. They’re particularly well-suited for indoor spaces or areas where fire safety and minimal maintenance are priorities. Thanks to their straightforward design and materials, they typically have lower maintenance costs over their lifetime compared to oil-filled alternatives.