8 Causes of Transformer Failure

Share

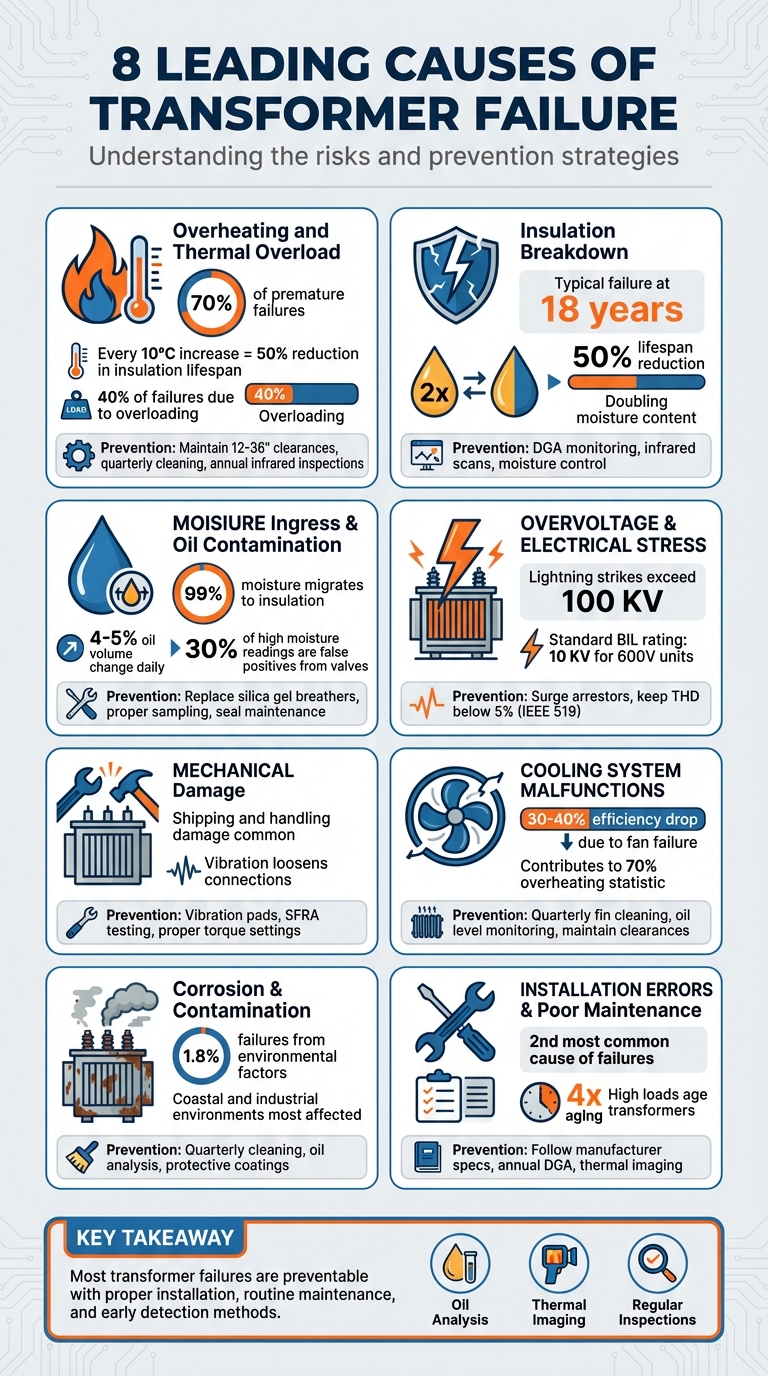

Transformers are critical to the electrical grid, but when they fail, the consequences can be severe - ranging from operational downtime to costly repairs. Here are the eight leading causes of transformer failure:

- Overheating and Thermal Overload: Excessive heat reduces insulation lifespan, with overloading and poor cooling accounting for 70% of failures.

- Insulation Breakdown: Aging and thermal stress weaken insulation, often leading to failures around 18 years of use.

- Moisture Ingress and Oil Contamination: Moisture damages oil and insulation, accelerating aging and increasing failure risk.

- Overvoltage and Electrical Stress: Lightning strikes, voltage spikes, and short circuits degrade components, causing arcing and insulation failure.

- Mechanical Damage: Shipping, handling, and vibration can distort windings and loosen connections, setting the stage for failure.

- Cooling System Malfunctions: Blocked cooling pathways or fan failures lead to overheating and insulation degradation.

- Corrosion and Contamination: Salt, dust, and pollutants corrode components and reduce efficiency.

- Installation Errors and Poor Maintenance: Improper setup and neglected maintenance are major contributors to early failures.

Key Takeaway: Most transformer failures are preventable with proper installation, routine maintenance, and early detection methods like oil analysis and thermal imaging.

8 Leading Causes of Transformer Failure with Prevention Statistics

Why Transformers Fail (and How to Prevent It)

1. Overheating and Thermal Overload

Overheating is responsible for 70% of premature transformer failures. Here's why: for every 10°C (18°F) increase above the rated temperature limit, the lifespan of insulation is cut in half. If the operating temperature rises by 20°C (36°F), the failure rate can multiply by four.

But it's not just heat that takes a toll - overloading is another major stressor, contributing to 40% of transformer failures. Take this real-world example: a food processing facility faced weekly outages because a 500 kVA transformer was running at 115% of its capacity. The problem was only resolved after redistributing the load and upgrading to a 750 kVA unit.

Loose or corroded terminals can also wreak havoc. They create high-resistance connections, leading to dangerous hot spots. For instance, just 0.1 ohm of resistance at 100 amps can dissipate 1,000 watts of heat - similar to the output of a space heater. On top of that, harmonics from variable frequency drives or LED lighting can generate eddy currents undetectable by standard meters. Blocked air intakes and dust-covered cooling fins further restrict heat dissipation, compounding the problem.

It's important to understand how load impacts temperature. At 75% load, a transformer experiences about 60% of its maximum temperature rise, but at full load, thermal stress reaches its peak. Operating consistently above 80% load pushes the transformer into the "danger zone". Add to that ambient temperatures exceeding the standard design limit of 104°F (40°C), and the transformer is forced to operate beyond its thermal capacity.

To prevent overheating, follow these best practices:

- Maintain proper clearances: 12 inches for transformers under 112.5 kVA and 36 inches for those over 1,000 kVA.

- Clean cooling fins every quarter.

- Conduct annual infrared inspections to detect hot spots.

- Use true RMS meters to monitor loads accurately.

- In environments with high harmonic distortion, opt for K-factor rated transformers (e.g., K-13 or K-20).

2. Insulation Breakdown and Dielectric Failure

Insulation failure is a leading cause of transformer breakdowns, often occurring in units around 18 years old. This reflects the cumulative stress on insulation over time. Let’s break down the factors contributing to this degradation.

Thermal stress and electrical disturbances are the main culprits behind insulation breakdown. Over time, the cellulose paper insulation becomes brittle and prone to cracking. Moisture plays a critical role here - every time the moisture content doubles, the insulation’s lifespan is cut in half due to accelerated hydrolysis. When transformers overheat for extended periods, the cellulose becomes fragile, and repeated temperature fluctuations widen cracks, setting the stage for arcing and short circuits.

Electrical disturbances, such as lightning strikes or switching surges, can also exceed a transformer's Basic Impulse Level (typically around 10 kV for a 600 V unit), causing immediate insulation failure. Meanwhile, contaminants like dirt, salt, and oil impurities, along with moisture, further reduce the dielectric strength, making arcing more likely.

Among these, thermal stress is identified as the most common trigger for insulation failure.

Detecting Issues Early

Catching insulation problems early can prevent costly breakdowns. Techniques like Dissolved Gas Analysis (DGA) help identify gases such as hydrogen, acetylene, or methane, which indicate issues like thermal faults or arcing. Infrared scans are another effective tool, capable of identifying hot spots on bushings and connections. Routine maintenance is equally important - ensuring silica gel breathers and gaskets are intact to block moisture ingress and cleaning radiators to prevent heat buildup can significantly extend insulation life.

For instance, a European power producer used doblePRIME monitors to track DGA, moisture levels, and partial discharge after losing an 800 MVA generator transformer. Early detection of partial discharges in the Generator Step-Up tank, linked to tap changer activity, allowed timely intervention and avoided further failures.

3. Moisture Ingress and Oil Contamination

Moisture is one of the most harmful contaminants in transformer oil, often entering through a process called "breathing." As a transformer's load and surrounding temperature fluctuate throughout the day, the oil's volume can change by about 4% to 5%. When the oil cools and contracts, it creates a vacuum that pulls in external air. This natural process exposes the transformer to potential seal degradation and contamination.

"If a unit is not sealed properly, the oil preservation system will allow moisture to be drawn in as the oil cools and decreases in volume. Once in, it dissolves and does not reverse migrate." - SDMyers

Once moisture is drawn in, damaged seals speed up the contamination process. Aging gaskets are often the weak link, as they deteriorate over time, allowing air - and the moisture it carries - to bypass the protective system. Another common issue is with saturated silica gel breathers. When the desiccant isn't replaced after becoming saturated, moist air flows directly into the tank. Even bottom valves can contribute to moisture ingress. Cooler ambient air can cause water to condense inside the valve body, which explains why around 30% of oil samples that initially test high for moisture turn out to be "false positives." In these cases, the water is trapped in the sampling valve rather than in the main oil tank.

Once moisture enters the oil, it doesn't stay there - it migrates into the paper insulation. In fact, about 99% of the moisture ends up in the insulation, leaving just 1% in the oil. This is a big deal because moisture significantly speeds up the aging process of the transformer. For instance, when the moisture content in the paper doubles, its aging rate doubles as well. At a moisture content of 4.5% combined with a temperature of 90°C (around 194°F), moisture can vaporize at the transformer's hot spot, potentially leading to localized dielectric failure.

To detect moisture issues early, it's crucial to take proper oil samples. Flush one gallon of oil per inch of valve size before sampling to ensure you're testing oil from the main tank rather than condensation trapped in the valve. Keep an eye out for warning signs like damp gaskets, darkened oil, or wet stains on the tank. For transformers in storage, ensure they're kept in dry, well-ventilated areas. Units exposed to rain or high humidity may need to be baked in an industrial oven before they can be safely energized.

4. Overvoltage, Short Circuits, and Electrical Stress

Transformers face more than just thermal and insulation challenges - external electrical stresses can also wreak havoc on their performance and longevity.

Voltage spikes are particularly damaging. Lightning strikes rank among the most destructive causes, often driving voltage levels beyond 100 KV. For perspective, a standard 600-volt transformer is designed to handle transient voltages only up to its Basic Impulse Level (BIL) rating of 10 KV. But lightning isn’t the only culprit. High-voltage transients also arise from utility switching events, such as connecting or disconnecting capacitor banks or reenergizing systems after outages, which place significant strain on insulation. Even less dramatic scenarios, like load drops or faults in one phase of a three-phase system, can lead to voltage "swells" that weaken a transformer's internal components. These repeated stresses degrade insulation, paving the way for future failures.

When voltage spikes occur, the damage is often long-lasting. High voltage can erode winding insulation, leading to arcing, flashovers on bushing insulators, and internal flashovers above the oil level. Even if the transformer continues to operate after such an event, the internal damage - referred to by experts as "permanent scars" - weakens the windings and reduces the transformer's remaining lifespan.

"Electrical events, the violent kind, leave permanent scars even if the unit returns to service, shortening the time to the next incident." - ElectPower

Short circuits compound these issues. When insulation fails, it can create unintended high-current paths, resulting in extreme overheating, fires, or even ruptures. One particularly dangerous scenario involves inter-turn faults, where short circuits develop between adjacent turns of a winding. These faults often progress slowly, evading immediate detection by protective relays. However, they cause localized overheating, which can eventually lead to catastrophic transformer failure.

To mitigate these risks, several protective measures are essential. Installing surge arrestors can help keep voltage spikes within the transformer's BIL rating. Using power quality analyzers to monitor voltage over time is another key strategy, as overvoltage issues are often sporadic and difficult to detect without continuous tracking. According to IEEE 519 standards, total harmonic distortion (THD) for voltage should be kept below 5% for systems operating under 69 kV. After any significant electrical fault, performing mechanical checks like Sweep Frequency Response Analysis (SFRA) can help identify winding distortions caused by stress. Additionally, routine insulation resistance and winding resistance tests can detect weakened insulation before it fails completely.

sbb-itb-501186b

5. Mechanical Damage from Vibration and Handling

Beyond the thermal and electrical challenges already mentioned, mechanical damage is another key factor in transformer failures. In fact, physical stress often sets the stage for later electrical breakdowns. Transformers, with their tightly wound coils and bolted connections, are particularly vulnerable to mechanical forces, which can significantly impact their reliability.

Shipping and handling are common culprits. Shocks during transport can distort windings, shift core components, or even compromise the integrity of tank welds. Mistakes made during manufacturing - like loose blocking, poor brazing, or even a stray bolt left inside the tank - can create stress points that gradually degrade insulation.

Once operational, ongoing vibration can loosen electrical connections, bolts, and terminals, leading to overheating, arcing, or short circuits. Vibrations from nearby heavy machinery or even minor ground tremors can worsen the problem. As ElectPower aptly puts it:

"Mechanical stress, like vibration, shipping shock, or seismic activity, loosens things that should never be loose, and mechanical issues often precede electrical ones." – ElectPower

The best defense starts with proper installation. Todd Benadum of ELSCO Transformers highlights the importance of vibration-reduction pads, noting that they "can protect against minor vibrational movement from equipment or minor temblors that typically go undetected by people". After transport or seismic activity, conducting a Sweep Frequency Response Analysis (SFRA) is critical to detect any internal shifts before energizing the unit. Maintenance teams should also ensure all bolts are properly torqued, as vibrations during shipping can loosen these vital connections.

If you notice the transformer’s usual steady hum shifting to a harsh buzz, rattle, or crackle, it could signal loosened laminations or internal discharges - clear signs of mechanical issues. Addressing these problems is a necessary step to complement the electrical and thermal precautions already in place.

6. Cooling System Malfunctions

Keeping transformers cool is non-negotiable. When fans stop spinning, pumps fail, or cooling pathways get clogged, heat can build up fast - and the results can be catastrophic. In fact, overheating accounts for nearly 70% of premature transformer failures in industrial settings, adding to the thermal stress we've already touched on.

Mechanical breakdowns are often the root cause of cooling problems. Fan motors can burn out, belts can snap, or electrical supply issues can knock out cooling systems. On top of that, physical blockages like dust buildup or oil circuit obstructions can severely limit heat dissipation. As Fluke puts it:

"Culprits are often cooling oil circuit blockages or failed cooling fans".

For oil-filled transformers, low oil levels - often due to leaks - can cripple the cooling process.

When cooling fans fail, cooling efficiency can drop by as much as 30%–40%, which accelerates the breakdown of insulation materials. Higher operating temperatures shorten insulation lifespan even further. Considering many transformers are designed to handle a maximum ambient temperature of 104°F (40°C), even a slight temperature increase can push them into dangerous territory.

Preventing these issues takes regular maintenance. Here are a few key steps to keep your cooling system in check:

- Clean cooling fins and ventilation grilles every quarter using compressed air or a vacuum.

- Monitor oil levels in liquid-filled transformers through sight glasses.

- Ensure cooling fans are functioning as expected.

- Maintain proper clearances: smaller units need at least 12 inches of space on all sides, while larger transformers (over 1,000 kVA) require 36 inches or more for effective natural convection.

Annual infrared inspections are another powerful tool. Thermal imaging can spot hidden hot spots or radiator blockages that aren't visible otherwise, giving you the chance to fix issues before they spiral into a costly $50,000 repair. Regular attention to cooling systems is essential for avoiding further thermal or electrical failures.

7. Corrosion and Environmental Contamination

External conditions can significantly contribute to the gradual breakdown of transformer components, compounding any internal issues. Factors like moisture, salt-laden air, dust, and chemical pollutants can wreak havoc on metal parts, degrade protective coatings, and contaminate insulating oil. While external pollution and corrosive environments are responsible for about 1.8% of transformer failures, the damage often remains unnoticed until it becomes severe.

Transformers in coastal areas face accelerated corrosion due to salt in the air, which affects enclosures, bushings, and cooling fins. Meanwhile, inland installations are exposed to industrial chemicals and airborne pollutants, which attack tank walls and connections. Corrosion on internal tank surfaces can be especially problematic, as metallic byproducts mix with the oil, forming sludge that undermines insulation.

Dust buildup presents another challenge, particularly for air-cooled transformers. A layer of dirt can block efficient heat transfer from windings and cooling fins. When combined with moisture or oil residue, dust can create conductive paths on bushings, leading to arcing and insulation failure. Additionally, temperature fluctuations can strain seals and gaskets, allowing contaminants and moisture to infiltrate the system.

To combat these issues, regular cleaning and inspection are essential. Radiators and cooling fins should be cleaned quarterly to remove dust, while protective paint and bushing porcelain should be checked for cracks and repaired promptly to prevent rust and tracking. Free-breathing transformers require properly maintained silica gel breathers to ensure only dry air enters the tank. Keeping substations free of overgrown vegetation is also important, as it can block airflow or introduce debris. Beyond physical maintenance, chemical monitoring is equally critical.

Oil analysis acts as an early warning system for detecting contamination. Regular testing for moisture, acidity, and dissolved gases (DGA) can help identify problems before they lead to failure. In particularly harsh environments, adding shielding to block salt spray and corrosive vapors can provide extra protection. By managing environmental factors effectively, the lifespan of transformers can be significantly extended.

8. Installation Errors and Poor Maintenance Practices

Even the most reliable transformers can fail if installation or maintenance isn’t handled properly. In fact, manufacturing and installation-related mistakes rank as the second most common cause of transformer failures. These issues often surface within the first few years of operation. Early failures typically result from improper installation, using the wrong specifications, or operational missteps. Getting the installation right is just as important as choosing the right equipment to ensure smooth and uninterrupted operation.

Several common installation errors can seriously compromise transformer performance. These include using undersized transformers, placing them in locations that restrict airflow, or allowing contaminants to infiltrate during assembly. Another frequent issue is loose connections caused by incorrect torque settings, which can lead to excessive noise, overheating, or even short circuits over time.

On the maintenance side, neglecting routine care significantly speeds up a transformer's aging process. Running a transformer continuously under high loads can age it up to four times faster than normal operation. Without regular checks - like oil analysis, thermal imaging, and cooling system inspections - problems such as moisture buildup or sludge formation might go unnoticed until they cause a catastrophic failure. The fallout from such failures, including production halts, regulatory penalties, and equipment replacement, often costs far more than routine maintenance.

To avoid these pitfalls, it’s crucial to follow manufacturer guidelines closely and stick to a consistent maintenance schedule. Conduct post-shipping tests like SFRA, perform annual oil analyses with dissolved gas analysis (DGA), and use thermal imaging to identify early warning signs. Simple tasks like cleaning radiator fins and ensuring bolts are properly torqued help maintain mechanical integrity and efficient cooling. When combined with the thermal and electrical precautions discussed earlier, these practices form a solid foundation for long-term transformer reliability.

Conclusion

Transformer failures rarely happen without warning. Most problems stem from insulation breakdown, with manufacturing errors following closely behind as another common cause. Other factors, like overheating, moisture intrusion, voltage spikes, mechanical damage, cooling system issues, and external contamination, contribute to wear and tear, shortening the lifespan of the equipment. The silver lining? Many of these problems can be avoided with the right selection, proper installation, and routine maintenance.

Understanding these failure modes is essential for choosing the right transformer and taking steps to prevent issues before they arise. For example, operating a transformer under high loads can significantly speed up aging. To counter this, managing loads effectively and conducting regular diagnostics can extend the life of your transformer and help avoid catastrophic breakdowns. Methods like oil analysis, thermal imaging, and cooling system inspections can catch problems early. Additionally, running transformers below their maximum capacity helps preserve insulation, while tools like silica gel breathers and vibration pads offer extra protection against environmental threats. These proactive steps highlight the importance of integrating consistent monitoring into your maintenance plan.

Matching a transformer's specifications to your facility's actual needs - such as ensuring the correct BIL ratings and insulation type - can prevent premature failures caused by mismatched equipment. This echoes the earlier point about aligning equipment capabilities with operational demands. When sourcing transformers, having access to detailed condition data is invaluable.

Platforms like Electrical Trader (https://electricaltrader.com) provide a trusted marketplace for buying and selling transformers, offering detailed condition reports that help you avoid units with hidden defects or maintenance issues. Whether you’re purchasing new equipment or evaluating used options, having this transparency reduces the risk of unexpected problems. By leveraging platforms like Electrical Trader, you can make informed decisions, minimize risks, and protect your investment. This comprehensive approach ensures your equipment performs reliably for the long haul.

FAQs

How does regular maintenance help prevent transformer failures?

Regular upkeep is key to ensuring transformers operate safely and to avoid expensive breakdowns. Scheduling routine inspections - usually annually for oil-filled transformers - allows technicians to spot common problems like low oil levels, moisture contamination, or worn-out seals and gaskets. Catching these issues early is crucial in preventing insulation breakdown, a major cause of transformer failures.

Maintenance tasks often include tightening loose connections, clearing debris, and tracking temperature patterns (measured in °F). Early signs like overheating, unusual vibrations, or discolored oil can signal underlying issues. Addressing these promptly - whether by replacing seals or reconditioning oil - can stop small problems from escalating into serious failures.

To make maintenance smoother, Electrical Trader offers an easy-to-use marketplace for sourcing replacement parts and equipment. This helps extend the life of transformers while reducing downtime.

What are the early warning signs of transformer insulation failure?

Early signs that a transformer's insulation might be failing include rising winding temperatures, unusual humming or buzzing noises, and excessive vibrations. You might also notice surface arcing, discolored oil, or evidence of moisture contamination.

Tackling these problems quickly can save you from more serious damage and expensive downtime. Routine maintenance and inspections play a crucial role in catching these issues early, keeping your transformer running smoothly.

Why is overheating one of the main causes of transformer failure?

Overheating is one of the leading culprits behind transformer failures. When winding temperatures exceed their intended limits, the insulation begins to deteriorate. Over time, this wear and tear makes the insulation brittle and more likely to fail. Once it breaks down, short circuits can occur, which may result in the transformer malfunctioning or completely failing.

Several factors can lead to overheating, including overloading the transformer, inadequate ventilation, or high ambient temperatures. To mitigate these risks, it’s crucial to keep an eye on transformer loads, maintain effective cooling systems, and conduct regular maintenance checks. These proactive steps can help spot and resolve potential problems before they escalate.