IEC vs. ANSI Voltage Standards: Comparison

Share

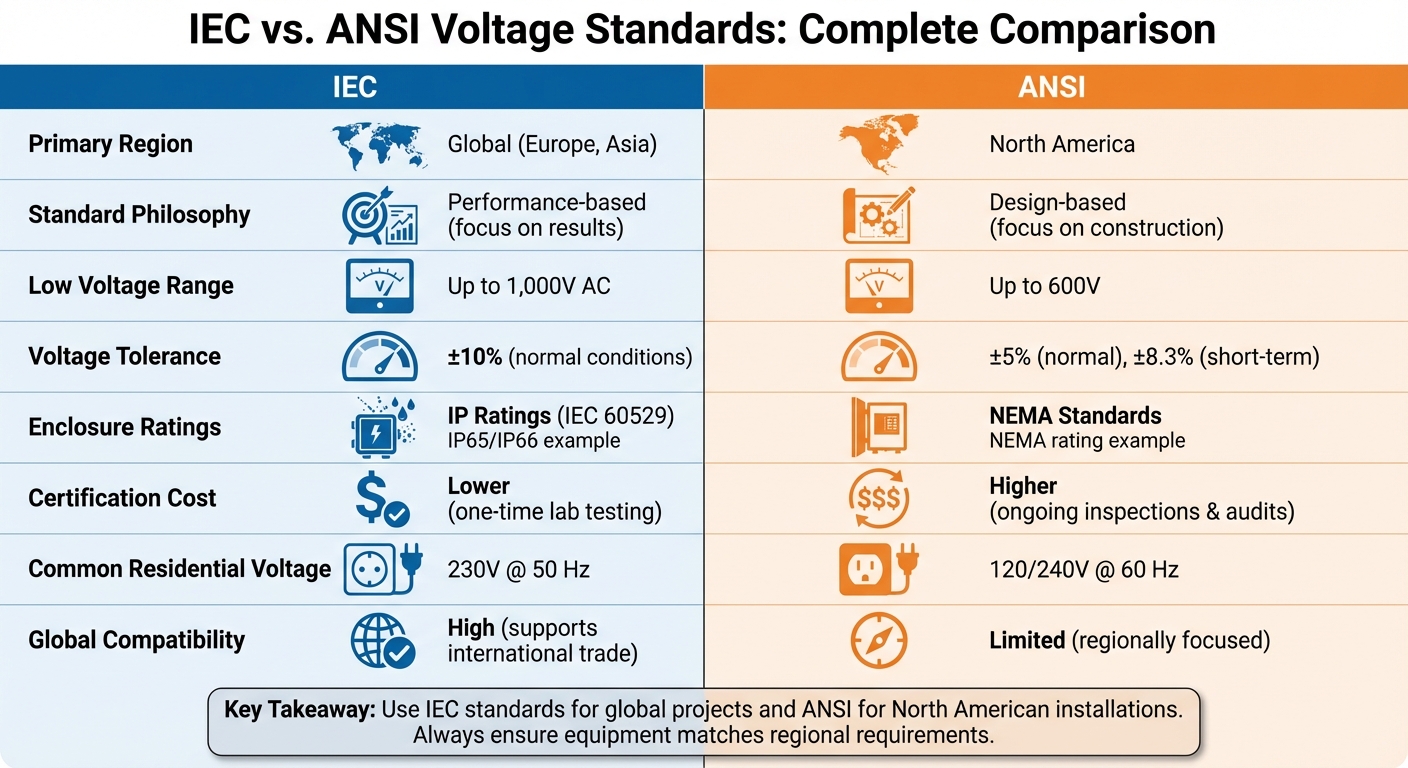

Choosing between IEC and ANSI voltage standards depends on your location and project needs. IEC standards are commonly used worldwide, especially in Europe and Asia, while ANSI standards dominate in North America. The two differ in their approach: IEC focuses on performance outcomes, while ANSI emphasizes design specifications. These differences affect compatibility, safety, and equipment selection.

Key Differences:

- Regional Use: IEC is global; ANSI is North America-specific.

- Voltage Ranges: IEC defines low voltage up to 1,000V; ANSI caps it at 600V.

- Tolerance: IEC allows ±10%; ANSI uses ±5% for normal conditions.

- Enclosure Ratings: IEC uses IP ratings; ANSI relies on NEMA standards.

- Certification Cost: IEC is cheaper, requiring one-time lab tests. ANSI involves ongoing inspections.

Quick Comparison:

| Factor | IEC Standards | ANSI Standards |

|---|---|---|

| Primary Region | Global (Europe, Asia) | North America |

| Standard Philosophy | Performance-based | Design-based |

| Voltage Range (LV) | Up to 1,000V | Up to 600V |

| Tolerance | ±10% | ±5% (normal), ±8.3% (short-term) |

| Enclosure Ratings | IP ratings (IEC 60529) | NEMA standards |

| Certification Cost | Lower | Higher |

Key takeaway: Use IEC standards for global projects and ANSI for North American installations. Always ensure your equipment matches the standards required by your region to avoid compatibility issues or safety risks.

IEC vs ANSI Voltage Standards: Key Differences Comparison Chart

1. IEC Voltage Standards

Voltage Classifications

IEC 60038 is the key international standard for defining nominal supply voltages. It categorizes systems into low voltage (100V–1,000V), medium voltage (1kV–35kV), and high voltage (up to 1,200kV) for both AC and DC applications. Unlike ANSI C84.1, which focuses solely on 60 Hz systems, IEC 60038 covers both 50 Hz and 60 Hz systems.

For 50 Hz systems, typical three-phase voltages include 230/400V and 400/690V. The widely used 230/400V standard replaced older systems like 220/380V and 240/415V. In 60 Hz systems, common voltages are 120/208V, 277/480V, and 347/600V. The IEC also uses the concept of "Highest voltage for equipment" as a reference for design. For instance, equipment for an 11kV system is rated at 12kV to account for operational safety margins.

| Voltage Class | IEC 60038 Range | Typical Application |

|---|---|---|

| Low Voltage (LV) | Up to 1,000V AC | Commercial applications |

| Medium Voltage (MV) | 1kV to 35kV | Industrial power distribution |

| High Voltage (HV) | 35kV to 230kV | Power transmission |

| Extra-High Voltage (EHV) | Above 230kV | Long-distance transmission |

IEC standards specify that supply voltages should stay within ±10% of nominal under normal conditions. For low-voltage systems, the utilization range is typically +10% / -14%, allowing for a 4% voltage drop within consumer installations.

Temperature and Environmental Ratings

Beyond voltage classifications, IEC standards also address environmental and safety testing. Instead of prescribing specific design features, the IEC focuses on performance-based compliance. Temperature rise tests are critical, ensuring electrical components don’t overheat under load. Fire safety is addressed through glow-wire tests, while insulation ratings help prevent short circuits or ignition.

Environmental protection is managed using Ingress Protection (IP) ratings outlined in IEC 60529. These ratings use a two-digit system to indicate resistance to solids (first digit: 0-6) and liquids (second digit: 0-9). For example:

- IP65: Dust-tight and resistant to water jets.

- IP66: Dust-tight and resistant to powerful water jets - ideal for demanding environments like chemical plants or coastal areas.

However, IP ratings don’t cover corrosion or ice resistance, which are addressed separately in ANSI/NEMA standards.

Dielectric and Insulation Tests

For systems above 1,000V, equipment must be specified based on its maximum operating voltage - the highest voltage experienced during normal operation, excluding transients like switching or lightning. This ensures insulation can handle the system's peak demands. For systems at or below 1,000V, specifications align with the nominal voltage of the system.

Although insulation is rated for maximum voltage, certain operational characteristics - like transformer magnetizing currents or capacitor losses - may not perform optimally at these limits. As a result, specific equipment recommendations are necessary to define operational boundaries. These tests are essential for ensuring safety and compatibility across varying voltage conditions.

2. ANSI Voltage Standards

Voltage Classifications

The ANSI C84.1-2020 standard outlines nominal voltage ratings and tolerances specifically for North America's 60 Hz systems, covering a range from 100V to 1,200kV. Unlike IEC 60038, which applies globally, ANSI focuses solely on the 60 Hz systems used in North America. This distinction allows for precise operating tolerances that the standard defines.

ANSI's voltage classification differs from the IEC approach. Low voltage is defined as 600V or below, while medium voltage ranges from 600V to 69kV. Common nominal voltages under ANSI include 120V, 240V, and 480V, with 480Y/277V being widely used in industrial and commercial applications.

| Voltage Class (ANSI C84.1) | Voltage Range | Typical Application |

|---|---|---|

| Low Voltage (LV) | 600V and below | Commercial and residential |

| Medium Voltage (MV) | 600V – 69kV | Industrial distribution |

| High Voltage (HV) | 69kV – 230kV | Power transmission |

| Extra-High Voltage (EHV) | 230kV – 1,100kV | Long-distance transmission |

The standard defines two voltage variation ranges. Range A allows for a ±5% variation under normal operating conditions, while Range B extends this to ±8.3% for short-term or unusual conditions. According to the standard:

"Electrical systems should operate effectively and efficiently within [Range A] without experiencing stress or degradation".

Operating outside these ranges can lead to significant issues. For instance, undervoltage may cause motors to overheat, while overvoltage can result in insulation failure.

Temperature and Environmental Ratings

In addition to voltage classifications, ANSI establishes clear guidelines for environmental and thermal operating conditions. These standards focus on ensuring reliability by addressing service conditions and temperature limits critical for power equipment. Factors like heat, moisture, and oxygen are highlighted as leading causes of premature insulation aging and equipment failure. The 2020 update to ANSI C84.1 introduced Annex D, which provides guidance on voltage rise issues caused by distributed generation and storage systems.

Voltage tolerance bands outlined in the standard ensure that equipment operates effectively across varying seasonal and load conditions. If conditions push voltages beyond Range B limits, immediate corrective actions are required to prevent equipment damage. As Saurav Sarkar explains:

"ANSI is noted as more user-oriented, explicitly detailing mechanical aspects, unlike IEC which relies on manufacturer-user agreements".

This user-focused approach offers clear specifications for equipment under diverse operating conditions.

Dielectric and Insulation Tests

To maintain reliable system performance, ANSI mandates stringent dielectric and insulation testing protocols. These tests complement the voltage tolerance guidelines and protect against overvoltages caused by internal switching or external events like lightning. For example, ANSI C57.12, which applies to transformers, includes tests for dielectric strength, breakdown voltage, and the dielectric dissipation factor (tan delta).

Insulation resistance tests are another key requirement, helping identify potential faults and ensuring industrial power systems remain safe. Additional tests cover breakdown voltage, water content, and acidity to confirm insulation performance under environmental stress. For systems operating at 600V or below, the service voltage variation in Range A is limited to +5% to -5%, ensuring safe operation within thermal and electrical limits. This rigorous testing framework is especially important for higher voltages, such as those classified as "subtransmission" or "transmission" (typically above 34.5kV), which often rely on load-tap changing transformers or voltage regulators to maintain stability.

ANSI vs IEC Short Circuit Calculation Procedure.

sbb-itb-501186b

Pros and Cons

IEC and ANSI standards serve different purposes based on regional and operational needs. In North America, ANSI standards dominate and are deeply integrated into local building and safety codes. On the other hand, IEC standards are widely used across the globe, particularly in Europe and Asia, making them a key factor in international trade and compatibility efforts. The table below highlights their main differences and sets the foundation for understanding their cost and compliance implications.

| Factor | IEC Standards | ANSI Standards |

|---|---|---|

| Primary Region | Global (Europe, Asia, etc.) | North America |

| Standard Philosophy | Performance-based (focus on results) | Design-based (focus on construction) |

| Global Compatibility | High; supports international trade | Limited; regionally focused |

| Certification Cost | Lower; single lab testing required | Higher; ongoing inspections needed |

| Design Flexibility | Greater freedom for manufacturers | More rigid specifications |

| Safety Scope | Electrical and electronic safety | Electrical, mechanical, and fire safety |

| Voltage Variation | IEC: ±10% | ANSI: ±5% (normal), ±8.3% (short-term) |

One of the most notable cost differences lies in certification. IEC standards typically require a one-time laboratory test, keeping costs relatively low. In contrast, ANSI/UL certification involves ongoing factory inspections, periodic audits, and compliance checks, which can significantly raise expenses. However, ANSI standards cover a broader safety scope, including mechanical hazards, fire resistance, and durability, areas that IEC standards do not emphasize as thoroughly. This balance between cost and safety has long-term implications for manufacturers and operators alike.

"Since IEC is applicable worldwide, across many countries where local practices, codes and legal environments vary drastically, the standards are more performance-based".

In North America, ANSI compliance is a legal requirement, while IEC standards are more focused on facilitating global compatibility. For instance, IEC/IP-rated enclosures offer manufacturers more design flexibility to meet diverse regulatory requirements. This trade-off between cost and flexibility reflects the fundamental differences in how these standards approach performance and design.

Voltage classifications also differ. ANSI defines low voltage as 600V and below, while IEC extends the range to 1,000V AC. This difference directly affects equipment selection. Residential systems further highlight this divide: ANSI systems commonly operate at 120/240V at 60 Hz, whereas IEC 60038 specifies 230V for single-phase systems, typically at 50 Hz. These differences make the standards non-interchangeable, as equipment designed for one often cannot meet the performance and temperature rise requirements of the other.

Conclusion

Choosing the correct voltage standard for your region is essential for ensuring compliance, safety, and efficiency. When deciding between international and regional standards, consider the location and regulatory framework of your project. In North America, ANSI standards are often tied to local building and safety codes, making them a legal requirement for many installations. On the other hand, IEC standards - widely adopted worldwide - offer manufacturers more design flexibility due to their performance-based approach. Recognizing these regional distinctions is crucial when specifying and designing equipment.

Always check regional compliance and avoid mixing voltage classes within a single specification. Equipment designed for one standard often requires physical and electrical adjustments to meet the requirements of another. For example, ANSI-rated equipment typically follows NEMA enclosure standards, while IEC-rated equipment uses IP ratings, each with unique voltage tolerance guidelines. To ensure compliance, verify certifications and select equipment that aligns with the country-specific rules where your project is based. Platforms like Electrical Trader can help you source new or used components, such as breakers, transformers, and power distribution equipment, that meet IEC or ANSI certifications. Using properly certified equipment not only simplifies compliance but also reduces project risks and enhances system performance.

Ultimately, regional requirements drive equipment decisions, especially for systems above 34.5 kV, where utility specifications often determine the applicable standard.

FAQs

What are the main differences between IEC and ANSI voltage standards?

The key differences between IEC and ANSI voltage standards lie in their classification of voltage levels and where they are applied. Here's how they break down:

- ANSI Standards: Low voltage is classified as up to 1 kV, medium voltage ranges from over 1 kV to 69 kV, high voltage spans over 69 kV to 230 kV, and extra high voltage is anything above 230 kV.

- IEC Standards: Low voltage is also up to 1 kV, but medium voltage is defined as over 1 kV to 35 kV, high voltage covers over 35 kV to 230 kV, and extra high voltage exceeds 230 kV.

Another major difference is their regional usage. ANSI standards are primarily followed in North America, while IEC standards are more commonly used across the globe. These distinctions influence equipment design, compatibility, and regulatory compliance. Choosing the appropriate standard is crucial and depends on your location and specific technical needs.

What is the difference between IEC and ANSI standards, and how do they impact equipment compatibility?

IEC and ANSI standards set distinct technical requirements and testing procedures, shaping how equipment is designed and ensuring compatibility within specific systems.

IEC standards are globally recognized and prioritize interoperability across international markets. They offer detailed guidelines for devices like transformers and switchgear, aiming to facilitate seamless integration worldwide. In contrast, ANSI standards are developed with North American systems in mind. These focus on regional needs, such as voltage ratings and performance criteria tailored to the U.S. power grid.

The differences between these standards can significantly influence equipment design and functionality. For instance, voltage tolerances under ANSI standards vary from those outlined in IEC standards. This means that equipment designed for one standard often won't fully meet the requirements of the other. As a result, selecting equipment based on the intended region's standards is essential to ensure safety, optimal performance, and compliance with local regulations.

Why is it essential to use the correct voltage standard for your region?

Using the right voltage standard for your region is crucial for the safe and reliable operation of electrical equipment. Standards like ANSI in North America and IEC in other parts of the world establish nominal voltage levels and tolerances. These guidelines help prevent problems like overvoltage or undervoltage, which can harm or wear out equipment over time.

Following the correct standard also ensures your equipment is compatible with local power systems and meets regional regulations. For instance, North America commonly uses 120V/240V for residential and industrial settings, while many other regions follow IEC standards. Sticking to the proper standard minimizes safety hazards, avoids unnecessary inefficiencies, and keeps your equipment running as it should.