IEC vs. IEEE Standards for Impulse Testing

Share

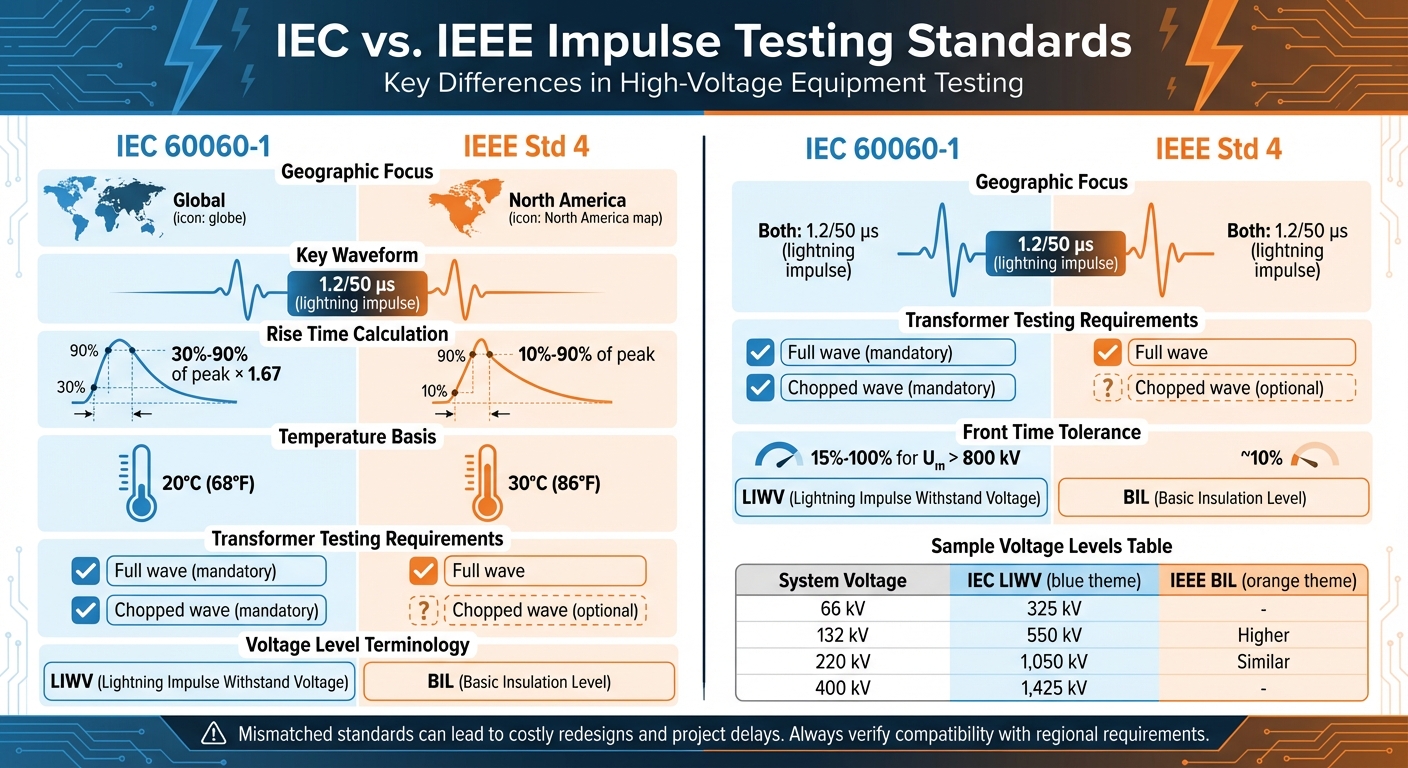

High-voltage equipment like transformers and cables must withstand electrical surges caused by lightning or switching events. To ensure safety and performance, two major standards guide impulse testing: IEC 60060-1 (used globally) and IEEE Std 4 (focused on North America). While both aim to verify equipment reliability, they differ in testing criteria, waveform definitions, and environmental assumptions. These differences can lead to costly redesigns if equipment built for one standard is used in a system governed by the other.

Key Differences:

- Waveform Parameters: IEC defines lightning impulses as 1.2/50 µs, with updated tolerances for ultra-high voltage systems. IEEE uses similar values but calculates rise time differently.

- Testing Procedures: IEC requires full and chopped wave tests for transformers, while IEEE often skips chopped wave tests unless requested.

- Environmental Factors: IEC assumes a 20°C ambient temperature, while IEEE bases tests on 30°C, reflecting regional conditions.

- Voltage Levels: IEC uses LIWV (Lightning Impulse Withstand Voltage), while IEEE refers to BIL (Basic Insulation Level). These terms and their values can differ, impacting compatibility.

Quick Comparison

| Aspect | IEC 60060-1 | IEEE Std 4 |

|---|---|---|

| Focus | Global | North America |

| Key Waveform | 1.2/50 µs (lightning impulse) | 1.2/50 µs (lightning impulse) |

| Rise Time Method | 30%-90% of peak (x1.67) | 10%-90% of peak |

| Temperature Basis | 20°C | 30°C |

| Transformer Testing | Full + chopped wave tests | Full wave tests (chopped optional) |

| Tolerance | Front time: 15%-100% (Uₘ > 800 kV) | Front time: ~10% |

When procuring equipment, ensure the standards align with your region's requirements to avoid costly delays or modifications.

IEC 60060-1 vs IEEE Std 4 Impulse Testing Standards Comparison

Exploring IEC60060 Impulse Voltage Generators: An Overview of Safe High Voltage Testing - LISUN

IEC 60060-1 Standards Overview

IEC 60060-1 establishes international guidelines for conducting dielectric tests on equipment operating above 1.0 kV AC or 1.5 kV DC. These tests include direct voltage, alternating voltage, impulse voltage, and their combinations. The 2025 Edition 4.0 introduces updates that improve clarity and expand the scope to include ultra-high voltage equipment.

Complementary standards, such as IEC 60060-2 and application-specific guides like IEC 60076-4 for transformers, build on this foundation. These updates refine critical impulse parameters, explained below.

Lightning and Switching Impulse Definitions

Lightning impulses (LI) are characterized by two key parameters: front time (T₁) and half-value time (T₂). The standard waveform for lightning impulses is defined as 1.2/50 µs. For ultra-high voltage systems (Uₘ > 800 kV), the positive tolerance for front time has been increased to 100%, allowing values up to 2.4 µs.

Switching impulses (SI) have undergone a significant update in the 2025 edition. The new standard defines switching impulses as 170/2500 µs. Additionally, the term "time-to-peak" has been replaced with "front time" to align the terminology with that used for lightning impulses. The allowable measurement uncertainty for the front time of standard lightning impulse voltages has also been revised, increasing from 10% to 15%.

IEC Testing Procedures

IEC 60060-1 provides detailed procedures for conducting withstand tests, including formulas for atmospheric correction factors. These adjustments account for environmental variables like temperature, humidity, and air pressure to ensure accurate results. The standard also includes instructions for both manual and digital evaluation methods. Annex C focuses on manual calculations, while Annex D addresses software-based evaluations. Environmental factors, such as precipitation, are also considered to maintain consistent and reliable test outcomes.

IEEE Std 4 Standards Overview

Unlike the globally focused IEC standards, IEEE Std 4 is designed specifically for North American applications. It serves as the go-to framework for high-voltage testing in the region, providing standardized methods for evaluating electrical equipment with voltages exceeding 1,000 V. This standard covers a range of testing methods, including AC, DC, lightning and switching impulses, and impulse currents, as outlined by IEEE SA.

The 2013 revision brought a major shift by consolidating previously separate sections for different voltage types into a single, unified document. Another key update was the formal introduction of the concept of measurement uncertainty in high-voltage testing, enhancing both the precision and dependability of test outcomes.

High-Voltage Testing Methods

IEEE Std 4 outlines detailed procedures for measuring lightning and switching impulses, specifying the required test equipment and evaluation criteria. These methods are adapted to reflect environmental conditions typical to the United States. The standard also considers testing under various conditions, including dry, wet, and contaminated environments, ensuring its applicability to practical, real-world scenarios. Additionally, IEEE Std 1122-2024 defines the performance requirements for digital recorders used in impulse measurements.

IEEE Standards in U.S. Applications

The testing methods detailed in IEEE Std 4 are closely aligned with the needs of U.S. grid infrastructure and utilities. This standard is tailored to meet North American grid codes, seamlessly integrating with transformer-specific guidelines like IEEE C57.98, which focuses on impulse testing for power transformers.

One key distinction from IEC standards is the assumption of U.S.-specific environmental conditions. For example, IEEE standards account for an ambient temperature of 30°C (about 86°F), compared to the IEC's 20°C assumption. This adjustment reflects the operational realities of North American infrastructure and includes more conservative insulation margins.

For substation equipment, the testing approach varies by voltage class:

- Class I systems (1.2–242 kV): Focus on Basic Insulation Level (BIL) phase-to-ground measurements.

- Class II systems (362–800 kV): Include both BIL and Basic Switching Impulse Insulation Level (BSL) evaluations.

These tailored methods and environmental considerations make IEEE standards a preferred choice for U.S. utilities and infrastructure.

IEC vs. IEEE: Main Differences

While both standards outline the same nominal waveform values - 1.2/50 µs for lightning impulses and 250/2500 µs for switching impulses - their key differences lie in how these values are measured and interpreted. For instance, the IEC 60060-1 revision replaced the term "time-to-peak" with "front time" for switching impulses, whereas IEEE Std 4 sticks to its original terminology.

Waveform Parameter Comparison

The two standards diverge significantly in how they calculate rise time. According to IEC 60034-15, the front rise time is determined as 1.67 times the interval between the impulse reaching 30% and 90% of its peak value. In contrast, IEEE 522 measures rise time as the time it takes for the impulse to rise from 10% to 90% of its peak voltage. This difference in methodology can lead to variations in test results, especially for borderline cases where precision matters.

Another notable difference is in measurement uncertainty. The 2025 IEC update increased the tolerance for lightning impulse front time from 10% to 15%. Additionally, for equipment rated above 800 kV, the positive tolerance for front time was extended to 100% (2.4 µs). IEEE standards, on the other hand, generally maintain a 10% tolerance, though this can vary depending on the specific application.

Testing Procedure Differences

The practical testing approaches also set these standards apart. For transformer testing, IEC 60076-3 mandates both full lightning impulse tests and chopped wave tests, while IEEE C57 typically focuses on full wave tests, with chopped wave tests being less common. Similarly, short-circuit withstand testing is obligatory under IEC for transformers rated at 3,150 kVA or higher, but under IEEE, this test is optional unless explicitly requested.

These differences in testing procedures can create challenges when equipment designed to meet one standard is used in a system governed by the other. Such mismatches may lead to costly redesigns and delays. Additionally, atmospheric correction methods differ: IEC 60060-1:2010 adopted specific formulas for calculating correction factors, while IEEE continues to rely on standardized tables and adjustment factors.

sbb-itb-501186b

BIL vs. LIWV: Test Voltage Levels

The terms used in IEEE and IEC standards can significantly influence how equipment is designed, tested, and specified. For instance, IEEE uses the term Basic Lightning Impulse Insulation Level (BIL) to describe the peak voltage a device must endure during a lightning surge. Meanwhile, IEC refers to the same parameter as the Rated Lightning Impulse Withstand Voltage (LIWV).

When it comes to transformer testing, the procedures outlined by IEEE and IEC differ in key ways. IEEE relies on standards like C57.12.00 and C57.12.90 to define BIL testing for liquid-immersed transformers. On the other hand, IEC uses IEC 60076-3 to set LIWV requirements. Notably, the third edition of IEC 60076-3 introduced specific waveshape requirements, including the use of a "k factor" to refine impulse characteristics[19,21]. This update also aligned its test level tables with IEC 60071-1, which focuses on insulation coordination.

These differences can lead to complications when equipment is used internationally. For example, a 2025 case study in South America highlighted this issue. A buyer mistakenly ordered a transformer compliant with IEC standards for use in an IEEE-regulated grid. The IEC lightning impulse level was lower than the IEEE BIL requirement, resulting in a failed impulse test. This oversight caused a redesign that cost $75,000 and delayed the project by 12 weeks.

Test Voltage Level Comparison Table

The following table compares IEC 60076-3 LIWV levels for different rated voltages with IEEE BIL requirements. According to IEC 60076-3, the LIWV levels are 325 kV for 66 kV equipment, 550 kV for 132 kV, 1,050 kV for 220 kV, and 1,425 kV for 400 kV. IEEE standards, which are more commonly used in the U.S. and North America, generally specify different levels.

| Equipment Rated Voltage (RMS L-L) | IEC 60076-3 LIWV (kV) | IEEE C57.12.00/90 BIL |

|---|---|---|

| 66 kV | 325 | Varies by application |

| 132 kV | 550 | Higher than IEC |

| 220 kV | 1,050 | Similar to IEC |

| 400 kV | 1,425 | N/A |

Beyond transformers, the differences in testing methods extend to rotating machines. For example, IEEE 522-2023 specifies a surge test for new form coils at 2.86 times the rated line-to-line voltage. In contrast, ANSI/EASA uses the formula V = 2E + 1,000 V. Meanwhile, IEC 60034-15 calculates a test voltage of around 39,130 V for a 13.8 kV machine, slightly lower than the 39,437 V specified by IEEE 522. Additionally, IEEE 522-2023 suggests testing used machines at 75% of the standard surge voltage to account for insulation aging.

High-Voltage Equipment Testing Applications

When it comes to testing power transformers, IEC 60076-3 outlines the essential requirements, while IEC 60076-4 adds specific guidance for impulse testing procedures. On the other hand, the IEEE framework relies on C57.12.00 for general testing requirements and C57.98 for detailed testing guidance. These standards ensure that testing aligns with the unique demands of power transformers. Additionally, separate standards exist for other equipment, such as distribution transformers and circuit breaker bushings.

For distribution transformers, IEEE C57.138-2016 is the go-to standard for routine impulse testing in manufacturing settings. This standard provides "general test procedures for performing routine quality control tests that are suitable for high-volume, production line testing". It's particularly practical for manufacturers producing overhead, pad-mounted, or underground distribution units in large quantities.

Circuit breaker bushings require their own specific testing protocols. While general testing methods often follow IEEE Std 4 or IEC 60060-1, IEEE C57.98 offers additional guidance tailored to outdoor power apparatus bushings used in power circuit breakers. For reactors, IEC 60076-4 references IEC 60289, differentiating reactor testing methods from those used for transformers. These specialized standards highlight the need to select the appropriate guidelines based on the specific equipment being tested.

The choice between IEC and IEEE standards often hinges on regional factors. In the United States, Canada, and parts of Latin America, IEEE standards prevail because they align with local grid codes and utility expectations. Meanwhile, IEC standards are more commonly used for international projects in regions like Europe and Asia. For businesses sourcing used or surplus equipment from platforms like Electrical Trader (https://electricaltrader.com), understanding the applicable standards is crucial to ensure compatibility with local testing requirements.

Below is a summary of the key standards for various equipment types:

| Equipment Type | Primary IEC Standard(s) | Primary IEEE Standard(s) |

|---|---|---|

| Power Transformers | IEC 60076-3, IEC 60076-4 | IEEE C57.12.00, IEEE C57.98 |

| Distribution Transformers | IEC 60076 series | IEEE C57.138 (Routine tests) |

| Reactors | IEC 60076-4, IEC 60076-6 | IEEE C57.21 (General) |

| Circuit Breaker Bushings | IEC 60137 | IEEE C57.19.00, IEEE C57.98 |

Conclusion

IEC and IEEE impulse testing standards aim for the same outcome: ensuring high-voltage equipment can handle the electrical stresses it will face during operation. However, the methods they use to achieve this differ in key ways. IEC standards prioritize precision and global consistency, while IEEE standards focus on conservative designs with larger safety margins and more durable construction. These differences can have a noticeable impact on both costs and operational decisions.

Choosing between these standards isn't purely a technical matter - it’s also influenced by geography and market demands. IEC standards dominate in Europe, Asia, Africa, and the Middle East, while IEEE standards are prevalent in North America and parts of Latin America. As mentioned earlier, mismatches between these standards can lead to expensive redesigns and project delays.

"Understanding the subtle distinctions between IEC and IEEE standards allows engineers, businesses, and regulators to select the most suitable standards to ensure compliance, efficiency, and the successful integration of emerging technologies."

One expert emphasized that this knowledge is crucial when selecting equipment. For instance, when purchasing equipment - whether brand-new or used from platforms like Electrical Trader (https://electricaltrader.com) - it's vital to ensure the chosen standard aligns with the intended environment. For example, if you're considering installing an IEC-rated unit in an IEEE region, you’ll need to reconcile the BIL levels to avoid compatibility issues. Taking the time to verify this upfront can prevent costly mistakes and regulatory challenges later.

Neither standard is inherently better; each is tailored to meet specific regional and technical needs. The key is to choose the one that fits your local requirements, aligns with your equipment specifications, and satisfies the expectations of local inspection authorities. Ensuring your equipment complies with the appropriate testing standards is essential for smooth operations and regulatory compliance.

FAQs

What are the key differences between IEC and IEEE standards for impulse voltage testing?

The differences between IEC and IEEE standards for impulse voltage testing come down to their scope, focus, and areas of application. IEC standards take a global approach, addressing a wide variety of electrical components such as cables, transformers, and accessories. They place a strong emphasis on detailed procedures for test setups, waveform characteristics, and safety measures, ensuring consistency across international applications.

Meanwhile, IEEE standards are more targeted, concentrating on specific equipment like transformers and distribution systems. These standards focus on providing precise guidelines for aspects like quality control, lightning impulse testing, and surge immunity.

In short, IEC standards take a broader, system-level perspective, while IEEE standards are more focused on delivering detailed, equipment-specific instructions.

What are the key differences between IEC and IEEE standards for impulse testing, and how do they impact equipment design and costs?

IEC and IEEE standards approach impulse voltage testing differently, and these distinctions can influence equipment design and associated costs. IEC standards, recognized globally, aim to standardize electrical equipment, simplifying international compatibility. This can cut down on the need for multiple certifications and reduce redesign costs for companies targeting global markets. On the other hand, IEEE standards, predominantly followed in the United States, often emphasize durability and robustness. While this focus can lead to highly reliable designs, it may also result in over-engineering, driving up manufacturing and redesign expenses.

The testing methodologies further highlight these differences. IEC standards often encourage compact and efficient designs, whereas IEEE standards may lean toward heavier, more durable equipment to meet stricter requirements. Consequently, equipment designed to meet one standard might require adjustments to comply with the other, potentially adding to overall costs. Companies must carefully assess their target markets and compliance needs to strike the right balance between compatibility, performance, and cost efficiency.

Why do IEC and IEEE standards assume different ambient temperatures for impulse testing?

The IEC and IEEE standards take different approaches to ambient temperatures for impulse testing, reflecting their unique priorities.

IEEE standards typically set the ambient temperature at around 104°F (40°C). This higher temperature mirrors operational environments, aiming to ensure that equipment performs reliably under conditions it’s likely to face in actual use.

Meanwhile, IEC standards assume a lower ambient temperature, around 68°F (20°C). This choice prioritizes consistency in controlled laboratory settings, ensuring uniform testing conditions while maintaining safety margins.

These contrasting approaches underline their goals: IEEE emphasizes practical, real-world performance, while IEC focuses on standardized and repeatable testing conditions.