Checklist for Choosing Smart Grid-Ready Transformers

Share

Smart grid-ready transformers are advanced devices designed to improve power grid efficiency and reliability. They feature real-time monitoring, automated control, and bidirectional communication with SCADA systems. These capabilities make them essential for handling modern challenges like renewable energy integration and EV charging demands.

When selecting one, focus on:

- Voltage and Frequency: Ensure compatibility with your grid's primary and secondary voltages and operating frequency (e.g., 60 Hz in North America, 50 Hz in Europe/Asia).

- kVA Capacity: Match your load requirements, considering future expansion and environmental factors like temperature or altitude.

- Smart Features: Look for SCADA compatibility (IEC 61850, DNP3, etc.), on-load tap changers (OLTCs), and real-time sensors.

- Cooling and Protection: Choose appropriate cooling (ONAN, ONAF, or dry-type) and protection systems like differential relays and Dissolved Gas Analysis (DGA) for reliability.

- Efficiency: Opt for models compliant with DOE standards, with efficiency ratings of 98.5% or higher to reduce energy losses.

While these transformers cost 15–20% more upfront, they offer long-term savings by cutting downtime, reducing failures, and improving operational efficiency. Platforms like Electrical Trader can help you compare models based on your specific needs and budget.

Electrical Specifications to Check

Voltage Ratings and Frequency

Start by confirming the primary voltage - commonly 11 kV or 33 kV - and ensure the secondary voltage aligns with your equipment requirements, such as 400 V.

Frequency is another critical factor. North America typically uses 60 Hz, while Europe and much of Asia operate on 50 Hz. Using a transformer designed for the wrong frequency can lead to increased core losses, higher operating temperatures, and a shorter lifespan. Always check the nameplate for the transformer’s rated voltage and frequency.

Also, verify the tapping range, usually ±2.5% or ±5%, for fine-tuning voltage levels. The Basic Insulation Level (BIL) is essential as well, ensuring the transformer can handle transient overvoltages caused by lightning or switching surges. For a 15 kV voltage class, standard BIL values are 95 kV for distribution-class equipment and 110 kV for power-class equipment. Make sure the transformer's BIL exceeds the sparkover level of your protective surge arresters to protect the insulation.

Once these are checked, move on to load capacity to ensure proper sizing.

kVA Capacity and Load Requirements

To size your transformer correctly, convert power needs (kW) to apparent power (kVA) using the formula: kVA = kW / PF. Create a comprehensive inventory of all electrical loads, noting whether they are single-phase or three-phase, continuous or intermittent, and the type of equipment involved (e.g., motors, rectifiers, or UPS systems).

Consider diversity factors since not all equipment operates simultaneously. For motor-heavy systems, avoid exceeding 60% of the transformer's maximum capacity to account for inrush currents during startup. Add a buffer of 10%–25% for future expansion. Local codes often require continuous loads (those running for 3+ hours) to be sized at 125% of their rated current.

Environmental factors can also affect capacity. For every 10°C above 40°C (104°F), derate kVA capacity by 8%, and for every 330 feet above 3,300 feet, derate by 0.3%. Facilities with EV chargers, UPS systems, or variable frequency drives that produce harmonics exceeding 15% total harmonic distortion should specify a K-factor rated transformer or plan for derating the standard capacity.

Impedance and Vector Group

The transformer's internal characteristics also play a big role in system performance. Impedance, expressed as a percentage, determines the fault current during a short circuit. Low impedance improves voltage regulation but increases fault current, which can strain downstream equipment. High impedance limits fault current but may cause voltage instability. Conduct system fault or arc flash studies to determine the acceptable impedance range before making a selection.

The vector group defines the phase relationship between high-voltage and low-voltage windings. For most distribution and industrial applications, Dyn11 (Delta-Wye) is the standard configuration. If you plan to operate transformers in parallel or expand an existing system, the vector group must match exactly. Mismatched configurations can prevent parallel operation and lead to damaging circulating currents. Always verify the vector group of existing transformers before adding new ones to your network.

Smart Grid Integration Capabilities

SCADA Compatibility and Communication Standards

Smart grid-ready transformers must work effortlessly with your control systems. Beyond meeting electrical load demands, they should intelligently interact with the grid. The IEC 61850 standard lays the groundwork for modern substation automation, enabling seamless communication between equipment from various manufacturers. As one expert highlights:

The basic prerequisites for a high degree of automation are a future‐proof IT architecture in all parts of the power grid and a common 'language' for all components of the power grid.

When selecting transformers, ensure they support MMS (Manufacturing Messaging Specification) for vertical communication between monitoring devices and SCADA systems. For time-sensitive horizontal communication, GOOSE (Generic Object Oriented Substation Events) is essential for tasks like teleprotection tripping. Additionally, SMV (Sampled Measured Values) facilitates real-time power measurements by transmitting current and voltage data directly from sensors. For secondary substations using cellular networks, compliance with IEC 60870-5-104 is crucial. These protocols collectively enable automation and resilience in grid operations.

Ensure the communication hardware aligns with IEC 61850-3 standards, offering an operating range of –40°F to 167°F and strong EMI resistance. To maintain network reliability during equipment failures, integrate redundancy protocols like HSR (High-availability Seamless Redundancy) or PRP (Parallel Redundancy Protocol). If legacy systems rely on Modbus RTU/TCP, consider protocol converters to bridge them with modern architectures.

On-Load Tap Changers (OLTC)

On-load tap changers (OLTCs) take grid stability a step further by enabling voltage adjustments without interrupting operations. This is especially critical for handling fluctuating renewable energy inputs. While traditional mechanical tap changers are still in use, solid-state versions featuring IGBTs (Insulated Gate Bipolar Transistors) and thyristors offer faster response times and eliminate arcing. These advanced electronic systems allow remote performance monitoring through digital signal processing, giving operators real-time insights into voltage stability.

Given that tap changer failures account for 14% of all transformer failures, regular maintenance is key. Monthly checks should verify the physical tap position against control room indications, while quarterly tests should cover the full tap range. An annual Turns Ratio Test (TTR) is also recommended. Electronic OLTCs reduce maintenance costs by eliminating mechanical arcing and support condition-based maintenance, identifying potential issues before they escalate.

Grounding Configurations

Proper grounding is critical for both safety and efficiency, especially in systems tied to renewable energy or battery storage. A common configuration is Delta on the primary (utility) side and Wye with a grounded neutral on the secondary (inverter) side. This setup prevents overheating caused by circulating currents and provides the grounding reference inverters need for ground fault protection. As noted in industry research:

Choosing a wye with neutral winding on the transformer's secondary side provides solid grounding and greatly reduces the likelihood that the inverter will face imbalanced phase-to-ground voltages.

However, avoid a Wye configuration with neutral on the utility side in standard grid-export scenarios, as it can create circulating currents in the neutral conductor, wasting energy and generating excess heat. Before finalizing transformer specifications, always check the inverter manufacturer’s grounding requirements. For advanced monitoring, ensure the grounding interface follows IEEE 2815-2024 standards, which define technical specifications for smart distribution transformer terminals.

Introduction to Smart Grids, Architecture and Features

Cooling, Protection, and Efficiency

Smart grid-ready transformers rely on effective thermal management, strong protection systems, and energy-efficient operation to perform reliably and cost-effectively.

Cooling Systems

The choice of cooling method plays a key role in both installation and upkeep. Liquid-immersed transformers, which use either mineral oil or synthetic esters, are available in two main configurations: ONAN (natural convection cooling) for outdoor setups and ONAF (forced air cooling with fans) for higher load capacities. On the other hand, dry-type transformers rely on air for cooling, making them ideal for indoor locations that must meet strict fire safety codes.

Protection Mechanisms

Once cooling is addressed, protection systems ensure long-term transformer reliability. For smart grid-ready transformers, layered protection is critical for preventing failures and enabling predictive maintenance.

- Differential protection (87T/87TN) detects internal faults, such as phase or ground issues, almost instantly.

- In environments with high magnetic fields, like those near arc furnaces, Rogowski coil current sensors are preferred over traditional current transformers (CTs).

- Sudden pressure relays safeguard against rapid pressure spikes in the main tank and tap changer compartments, addressing failures that, while unlikely to cause fires, are significantly more frequent than catastrophic events.

Monitoring tools like Dissolved Gas Analysis (DGA) are indispensable for spotting early-stage faults before they escalate. For continuous oversight in smart grid systems, install online gas-in-oil monitoring devices that feed data to SCADA platforms. Post-commissioning, DGA testing should be performed at intervals: 18–24 hours, one month, and six months. This schedule helps catch potential issues early. Importantly, never re-energize a transformer after a protective trip without conducting DGA and identifying the root cause.

Efficiency and Losses

Efficiency is a critical factor in managing operational costs, especially since transformers run 24/7. Modern units are built to comply with DOE 10 CFR 431 standards and are optimized for 35% loading, reflecting current usage patterns rather than the outdated 80–100% assumptions of older models.

NEMA Premium transformers offer a 30% reduction in energy losses compared to DOE minimum standards, though they often cost twice as much as standard aluminum-wound transformers. Despite the higher upfront cost, the long-term savings can be substantial.

Transformer losses come in two forms:

- No-load losses, which remain constant.

- Load losses, which increase exponentially with the load (by the square of the load).

These losses generate heat, placing additional strain on HVAC systems and driving up cooling costs. Upgrading from a transformer with 98.5% efficiency to one rated at 99.14% can pay for itself in less than a decade. To optimize performance, conduct a 30-day load study and size the transformer to actual demand with a 25% margin. This approach often allows for downsizing from legacy ratings and can cut cooling airflow needs by over 300 cfm, further reducing energy consumption.

sbb-itb-501186b

Physical and Environmental Requirements

Before choosing a transformer, make sure it fits your site and can handle your local environmental conditions. This step is crucial for smooth installation and reliable long-term performance.

Size and Weight

Once you've confirmed the electrical and smart grid requirements, check if the transformer's physical design aligns with your site's limitations. Features like higher Basic Insulation Levels (BILs), winding shielding, or specialized winding shapes - often included to improve transient protection - can increase the transformer's size and demand extra space beyond its base dimensions.

Also, ensure your site can handle the transformer's weight and overall footprint. Adequate space for maintenance access is essential, so rely on the manufacturer's specifications and operational data. For HVAC planning, use actual watt loss data provided by the manufacturer at different load levels (25%, 50%, 75%, and 100%) instead of generic BTU ratings.

Environmental and Compliance Standards

Your environment and compliance with relevant standards play a significant role in how well your transformer performs. While efficiency and protection systems are tailored to operational loads, environmental factors can directly impact longevity and reliability.

Transformers are typically rated for operation at altitudes below 3,300 feet (1,000 meters). If your site is at a higher elevation, the transformer will need to be derated because thinner air reduces both cooling efficiency and dielectric strength. Ambient temperature also affects insulation performance. For instance, liquid-filled transformers usually trigger alarms between 60°C and 90°C, while dry-type transformers have higher thresholds, ranging from 180°C to 200°C.

"The health and preservation of the insulation material has a far greater impact on the transformer lifespan... transformer loading has a much greater impact on transformer life." - NEMA

Finally, confirm that your transformer complies with U.S. standards. Key standards include IEEE C57.12.00-2021 for liquid-immersed transformers, IEEE C57.12.01-2020 for dry-type units, NEMA TR 1 and NEMA ST 20 for purchasing specifications, IEEE 2815-2024 for smart distribution transformer terminals, and IEEE C37.91-2021 for protection systems on transformers exceeding 5 MVA and 10 kV .

Using Electrical Trader for Smart Grid-Ready Transformers

Once you've nailed down your technical needs, Electrical Trader can help you find both new and used smart grid-ready transformers. Their centralized platform simplifies the selection process by aligning your requirements with their extensive inventory. Whether you're after 3-phase transformers, substation transformers, or units with advanced monitoring features, Electrical Trader has you covered. Use their powerful filter options to fine-tune your search and zero in on the right equipment.

Browse Product Listings

To narrow down your options, take advantage of Electrical Trader's search filters. You can sort the inventory by KVA or MVA rating, primary voltage, and secondary voltage. Popular sizes like 15, 30, 45, 75, 112.5, 150, 225, 300, 500, 750, and 1,000 KVA are readily available. For smart grid-ready transformers, focus on models equipped with Intelligent Electronic Devices (IEDs) and real-time monitoring sensors that track voltage, current, temperature, and oil levels. Additionally, units with communication features - such as wired Ethernet, cellular, or Wi-Fi - are essential for integration with SCADA systems.

You can also filter by enclosure type, like NEMA 3R for outdoor setups, and ensure the insulation type (liquid-immersed or dry-type) suits your operating environment. Always review datasheets for details on grid compatibility. Once you've narrowed your options, it's time to compare features and pricing.

Compare Features and Prices

Prices for transformers can vary widely depending on their capacity. Used units in the 100 to 500 KVA range typically cost between $1,200 and $7,000, while larger models in the 1,000 to 2,500 KVA range are priced from $30,000 to $70,000. To get the best value, consider the total cost of ownership by factoring in efficiency and energy loss data. While high-efficiency transformers may have a higher upfront cost, they often lead to lower operating expenses over time.

Check datasheets to ensure compliance with local grid requirements, including tapping configurations and short-circuit handling capabilities. It's also important to match impedance values with your existing switchgear to safely manage short-circuit currents. For added flexibility, consider selecting a transformer with a slightly higher KVA capacity to accommodate future load growth.

Selection Checklist

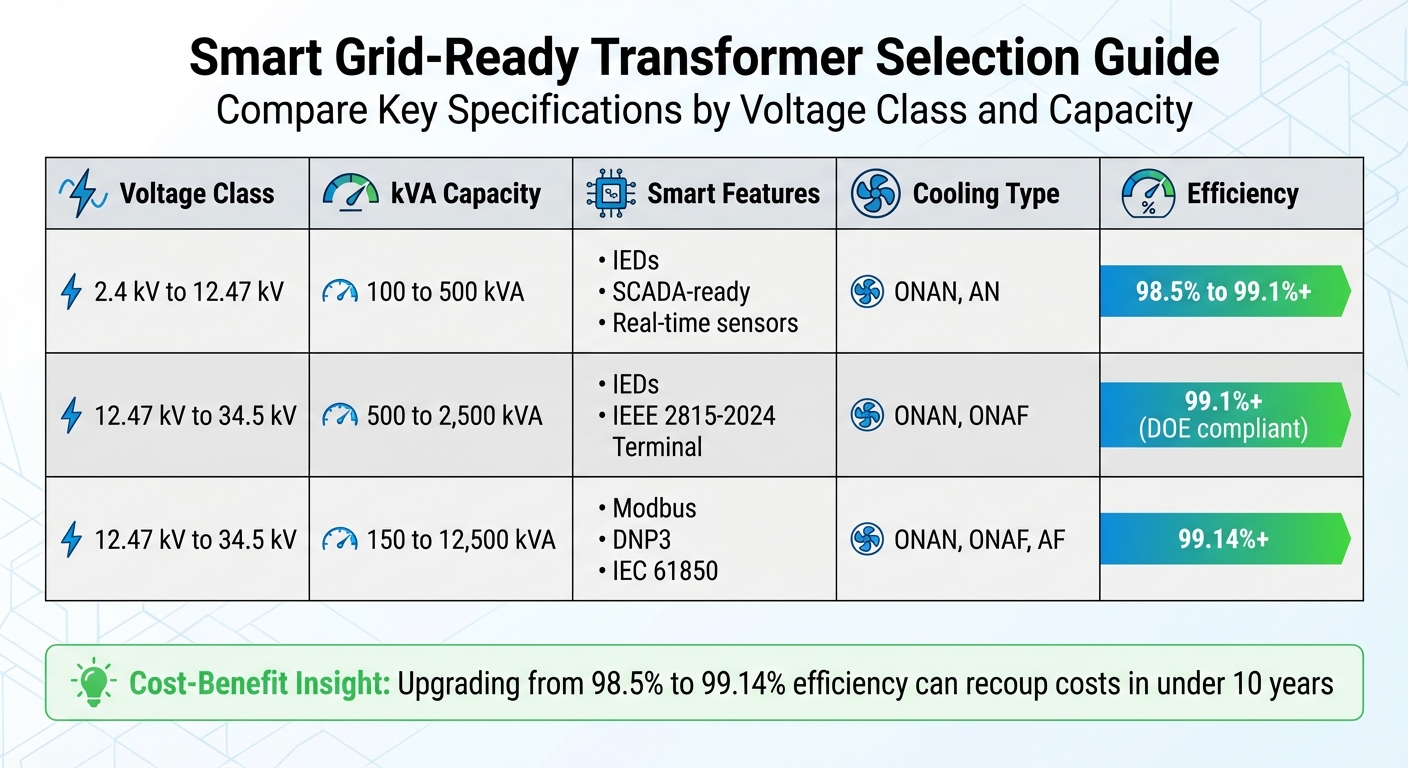

Smart Grid-Ready Transformer Selection Comparison by Voltage Class and Capacity

Use this checklist to ensure all critical specifications are covered. Start by confirming that voltage ratings and BIL meet grid requirements. Determine the kVA capacity based on a thorough load study, considering both current needs and potential future growth. Aim for an operational efficiency range of 50–80%.

Check impedance levels through fault studies to ensure compatibility with existing switchgear . These steps align closely with the essential electrical and smart integration parameters discussed earlier.

Make sure the unit includes Intelligent Electronic Devices (IEDs) and supports your SCADA protocol, whether it's IEC 61850, DNP3, or Modbus TCP. Verify that the cooling system - be it ONAN, ONAF, or dry-type AN/AF - matches your ambient temperature and ventilation conditions. Additionally, confirm that the transformer meets DOE efficiency standards, with optimal performance at a 35% load. Lastly, ensure the enclosure's IP rating and anti-corrosion coatings are suitable for local environmental conditions.

Specification Comparison Table

The table below simplifies the comparison of transformer options based on key criteria:

| Voltage Class | kVA Capacity | Smart Features | Cooling Type | Efficiency |

|---|---|---|---|---|

| 2.4 kV to 12.47 kV | 100 to 500 kVA | IEDs, SCADA-ready, Real-time sensors | ONAN, AN | 98.5% to 99.1%+ |

| 12.47 kV to 34.5 kV | 500 to 2,500 kVA | IEDs, IEEE 2815-2024 Terminal | ONAN, ONAF | 99.1%+ (DOE compliant) |

| 12.47 kV to 34.5 kV | 150 to 12,500 kVA | Modbus, DNP3, IEC 61850 | ONAN, ONAF, AF | 99.14%+ |

Choose the voltage class and kVA capacity that align with your project needs, while ensuring the smart features required for seamless grid integration are included. Keep an eye on total cost of ownership - upgrading from a 98.5% efficient transformer to one with 99.14% efficiency could recoup its cost in under 10 years.

Conclusion

Choosing the right smart grid-ready transformer means balancing technical requirements with long-term objectives. Start by focusing on the basics - voltage ratings, kVA capacity based on actual load assessments, and ensuring impedance works seamlessly with your current switchgear. From there, consider adding critical smart features like real-time monitoring via Intelligent Electronic Devices (IEDs), SCADA compatibility using protocols such as IEC 61850 or DNP3, and predictive maintenance capabilities, which could reduce downtime by up to 45%.

Adapt the cooling system, IP rating, and insulation class to match your specific site conditions, whether you're dealing with coastal humidity, industrial dust, or significant temperature fluctuations.

While smart transformers come with a 15–20% higher initial cost, they offer energy savings, longer equipment lifespan, and condition-based maintenance that pays off over time.

Once your technical and environmental needs are clear, explore the marketplace for solutions tailored to your requirements. When you're ready to compare options, Electrical Trader offers a centralized platform to browse new and used smart grid-ready transformers, review specifications, and evaluate pricing. Use the checklist and comparison table from this guide as a starting point.

FAQs

What smart features should you consider when choosing a smart grid-ready transformer?

When choosing a smart grid-ready transformer, prioritize features like real-time monitoring to keep tabs on performance and remote control capabilities for hassle-free management. Look for models that support integration with sensors and communication modules, boosting connectivity and data sharing. Additional features, such as automation for load management and tools for system optimization, can significantly enhance energy efficiency and ensure reliable operation. These advanced functions allow the transformer to meet the evolving needs of modern grids, making it a smart choice for sustained performance.

How does the cooling method affect transformer performance?

Cooling is essential for keeping transformers running smoothly. It helps manage heat levels, ensuring the transformer stays within safe temperature limits. This prevents overheating, protects the insulation, and reduces thermal stress on internal parts.

Choosing the right cooling method not only enhances reliability but also extends the transformer’s lifespan. It’s a crucial consideration when determining the best option to meet your specific requirements.

Why should future growth be a factor when choosing the kVA capacity of a transformer?

When choosing the kVA capacity of a transformer, planning for future growth is crucial. This ensures your system can meet rising power demands over time without compromising reliability or voltage stability. Plus, it helps you avoid the hassle and expense of early upgrades or replacements, which can disrupt operations and strain budgets.

By considering potential load increases from the start, you can select a transformer that aligns with your long-term needs. This not only supports efficient power distribution but also provides flexibility for scaling as demands evolve.