How Thermal Aging Affects Electrical Insulation Lifespan

Share

Thermal aging reduces the lifespan of electrical insulation by causing chemical and structural damage when exposed to high temperatures. Key effects include oxidation, chain scission, and brittleness, which lead to cracks, reduced electrical resistance, and safety hazards like fires. For every 10°C (18°F) increase in operating temperature, insulation lifespan is halved. Materials like XLPE and EPR degrade over time due to antioxidant depletion and structural changes. Proper material selection, temperature monitoring, and maintenance are critical to extending insulation life and preventing failures.

Key Takeaways:

- Degradation Process: Heat triggers oxidation and weakens the polymer structure, leading to cracks and reduced performance.

- Lifespan Rule: A 10°C rise in temperature halves insulation lifespan.

- Material Impact: XLPE, EPR, and PVC age differently; for example, recycled PVC lasts only ~6.3 years at 140°F.

- Performance Decline: Aged materials show reduced breakdown voltage, increased conductivity, and brittleness.

- Prevention: Use high-quality materials, monitor temperature, and perform regular maintenance to minimize aging effects.

Thermal aging is a major factor in insulation failure, but proactive steps can mitigate its impact and extend the lifespan of electrical systems.

How Thermal Aging Damages Electrical Insulation

How Thermal Aging Works

When exposed to heat, materials like XLPE and EPR undergo chemical and physical changes that permanently weaken their structure. The process begins with thermo-oxidation - a reaction between heat, oxygen, and the polymer. This depletes the built-in antioxidants, leaving the polymer chains unprotected and more prone to damage.

Once antioxidants are exhausted, the polymer chains start breaking down through chain scission, leading to the formation of polar groups (such as carbonyl and hydroxyl). These groups trap charges, causing distortion in the internal electric field. For example, studies on aged DC XLPE samples revealed a 120% distortion in the electric field under -50 kV/mm after just 168 hours of thermal aging.

"The newly generated oxygen-containing groups provided deep trapping sites (~0.95 eV) for space charges and caused severe electric field distortion (120%) under −50 kV/mm at room temperature in the aged DC XLPE samples." – MDPI Polymers

Heat also affects the physical structure. In XLPE, spherulites - crystalline structures within the polymer - expand significantly with aging. Their diameter increases from 10–20 μm in unaged material to 50 μm after prolonged heat exposure. This structural change creates tiny cracks and voids, allowing moisture and contaminants to penetrate. These flaws increase ion mobility, leading to higher conductivity. For instance, XLPE's conductivity jumps from 1.25×10⁻¹⁶ S/m to 6.50×10⁻¹⁵ S/m after 48 days at 302°F (150°C). These combined chemical and structural changes are key contributors to the insulation's declining performance and reduced lifespan.

Performance Decline in Aged Insulation

The chemical and structural damage caused by thermal aging has a direct impact on both the electrical and mechanical performance of insulation. Electrically, the material's ability to resist voltage breakdown diminishes. For example, epoxy/glass fiber composites aged at 356°F (180°C) for 360 hours saw their DC breakdown voltage drop from 168.28 kV/mm to 134.91 kV/mm. Additionally, the dielectric loss factor, which measures energy lost as heat, increased by 126.35% after 48 days of accelerated aging.

Mechanically, the insulation becomes brittle and less flexible over time. One critical measure of this is elongation at break - the amount a material can stretch before it snaps. As thermal aging progresses, this value declines sharply. For XLPE aged at 302°F (150°C), elongation at break retention dropped to 50.12% after just 48 days, signaling the end of its service life. Tensile strength also weakens, making the material more prone to cracking under everyday stresses like vibration or temperature changes. These combined effects highlight the severe performance degradation that thermal aging can cause.

sbb-itb-501186b

What Speeds Up Thermal Aging

Operating Temperature and Service Conditions

Temperature is the most critical factor driving thermal aging. Montsinger's rule highlights this relationship: every 8–10°C (about 14–18°F) increase in operating temperature cuts the lifespan of equipment in half. Even minor deviations above the design temperature can have a drastic impact on a cable's longevity.

For XLPE insulation, the danger zone lies between 230°F and 275°F (110°C and 135°C). Research conducted by Professor Larbi Boukezzi at Djelfa University shows that 2,000 hours of exposure within this temperature range causes significant material breakdown. Even operating at the lower end of this range - 248°F (120°C) - can lead to serious damage. Over a 48-day period, the dielectric loss factor can increase by 126.35%, and leakage current may rise by 38.18%.

Thermal cycling - repeated heating and cooling - intensifies the damage. This process introduces thermo-mechanical stress, which compounds the effects of thermal aging. When combined with electrical stress, the rate of degradation accelerates further, creating a multiplying effect rather than a simple additive one.

Apart from temperature and cycling, the material's design and inherent properties also influence how quickly it ages.

Material Properties and Design Factors

The rate of thermal aging is also shaped by the material's chemical makeup and structural design. Not all insulation materials age the same way. For example, XLPE's performance heavily depends on antioxidants. Once these antioxidants deplete, the material deteriorates more rapidly due to thermo-oxidative processes. Additionally, thermal aging disrupts XLPE's polymer structure, loosening the matrix and expanding spherulites, which increases charge carrier mobility and accelerates degradation.

PVC insulation faces different challenges. Under thermal stress, it suffers from plasticizer loss, leading to brittleness and reduced flexibility. While new PVC insulation is typically designed to last 30 years, recycled PVC can degrade much faster - sometimes in just 6.3 years when exposed to temperatures of 140°F (60°C). On the other hand, EPR (Ethylene Propylene Rubber) shows better resistance to high temperatures, retaining its breakdown strength more effectively under thermal stress.

Manufacturing defects, such as voids, cavities, or protrusions, also play a role in accelerating thermal aging. These imperfections concentrate thermal damage, speeding up the overall deterioration process.

Accelerated Heat Aging of Data Cable Insulation Materials for Power over Ethernet (PoE) Applications

Insulation Material Performance Under Heat

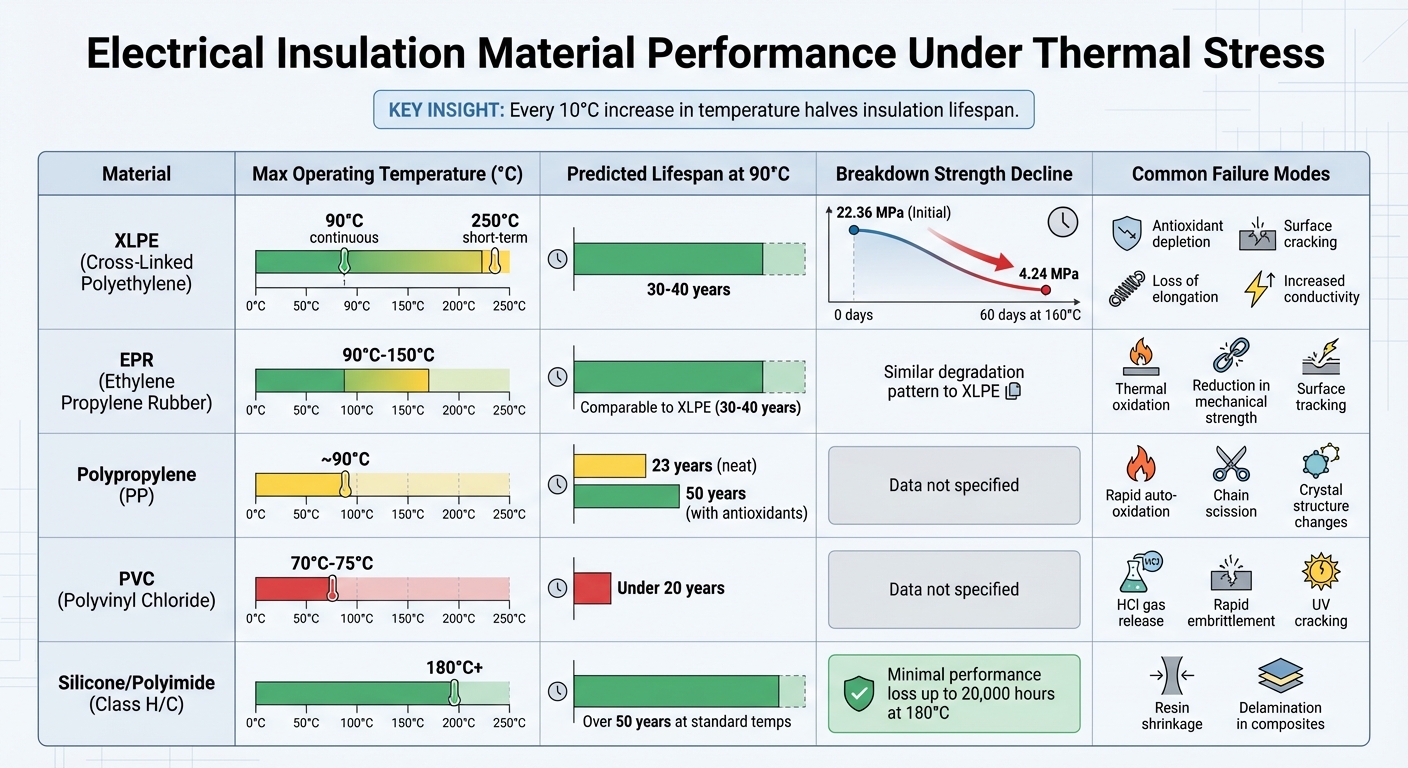

Electrical Insulation Material Performance Under Thermal Stress Comparison

Material Performance Comparison

This section dives into how various insulation materials perform under continuous thermal stress, helping to inform material choices for specific operating conditions.

Different insulation types respond uniquely to heat stress, which directly impacts their durability and effectiveness. The table below summarizes how some common insulation materials fare when exposed to prolonged high temperatures:

| Material | Maximum Operating Temperature | Predicted Lifespan (at 90°C) | Breakdown Strength Changes | Common Failure Modes |

|---|---|---|---|---|

| XLPE | 90°C continuous / 250°C short-term | 30–40 years | Drops from 22.36 MPa to 4.24 MPa after 60 days at 160°C | Antioxidant depletion, surface cracking, loss of elongation, increased conductivity |

| EPR | 90°C–150°C | Comparable to XLPE | Similar degradation pattern to XLPE | Thermal oxidation, reduction in mechanical strength, surface tracking |

| Polypropylene (PP) | ~90°C | 23 years (neat) / 50 years (with antioxidants) | - | Rapid auto-oxidation, chain scission, crystal structure changes |

| PVC | 70°C–75°C | Under 20 years | - | HCl gas release, rapid embrittlement, UV cracking |

| Silicone/Polyimide | 180°C+ (Class H/C) | Over 50 years at standard temps | Minimal performance loss up to 20,000 hours at 180°C | Resin shrinkage, delamination in composites |

Material composition and design play a critical role in how well insulation withstands thermal stress. For instance, activation energy - a measure of a material's resistance to heat - helps predict degradation rates. XLPE and EPR have nearly identical activation energies (103 kJ/mol and 102 kJ/mol, respectively), meaning they degrade at comparable rates under similar conditions.

Research continues to refine our understanding of material performance. In November 2024, Xiwen Wu at the University of Southampton demonstrated that adding antioxidants could double polypropylene's lifespan at 90°C - from 23 to 50 years. This finding aligns with the Arrhenius relationship, which predicts that every 10°C increase in temperature halves an insulation material's lifespan.

This comparison highlights the importance of choosing high-quality materials to enhance durability - an essential consideration for extending the lifespan of insulation systems.

How to Extend Insulation Lifespan

Choosing the Right Materials and Design

The first step in extending insulation lifespan is selecting materials that match the operating environment. Materials like Ethylene Propylene Rubber (EPR), Silicone Rubber, and Polyimide can reduce thermal aging by as much as 40% compared to standard options. For applications exposed to extreme heat, consider Class H materials (rated for 180°F) or Class C materials (rated above 200°F), such as aramid paper and silicone varnish, which are built to handle harsh conditions.

Good design is equally important. Features like proper ventilation, optimized layouts, and protective high-temperature coatings help prevent heat buildup and reduce oxidation, which can degrade insulation over time. For transformers, maintaining an operating temperature approximately 11°F below the rated hot-spot temperature can double the lifespan of the insulation.

Once the right materials and design are in place, the next focus should be on monitoring and maintenance to prevent temperature-induced wear.

Temperature Monitoring and Maintenance Planning

Even with the best materials and designs, ongoing temperature monitoring is critical to preserving insulation. Real-time systems provide key data to manage insulation proactively. Techniques like thermal imaging, insulation resistance monitoring, and dielectric spectroscopy can detect early signs of wear before they become visible. Condition-based monitoring systems are particularly effective, extending cable lifespans by 20–40% by identifying problems like hot spots and partial discharge early on.

For a more accurate prediction of insulation lifespan, use the Arrhenius equation with real operating temperature data instead of relying solely on rated values. Keep an eye on key indicators like IR (Insulation Resistance), Dissipation Factor (tan δ), and Partial Discharge (PD) to catch aging signs early. Since thermal aging often remains hidden for years, continuous monitoring is not just helpful - it's essential.

Buying Quality Electrical Components

The durability of insulation also depends on the quality of the electrical components in use. High-grade materials like XLPE or EPR offer design lifetimes of up to 50 years, compared to the 20–30 years typically seen with standard power cables. Avoid using recycled materials; for instance, recycled PVC has a thermal lifespan of only 6.3 years at 140°F, whereas new PVC can last up to 30 years.

Manufacturing quality plays a big role as well. Components should be free from defects like cavities, protrusions, and voids, as these can become weak points that accelerate aging. For transformers, consider sealed-style tanks and silica gel breathers to limit moisture and oxygen exposure, both of which can degrade insulation. Platforms like Electrical Trader make it easier to find reliable new and used components, including breakers, transformers, and power distribution equipment that meet rigorous thermal performance standards.

Conclusion

Thermal aging poses a serious threat to electrical insulation, affecting its chemical, mechanical, and electrical properties. Heat exposure leads to oxidation, chain scission, and brittleness, which can result in cracks and a decline in performance. This significantly increases the risk of failures. According to the National Fire Protection Association (NFPA), "32% of home fires involving electrical distribution equipment commence with electrical wires or cable insulation ignition". These risks highlight the importance of effective thermal management strategies.

Proper practices can mitigate the effects of thermal aging. Operating temperature plays a major role - following the 10°C rule, every 10°C increase in temperature cuts insulation lifespan by half. Material selection is equally important. High-performance materials, such as EPR, Silicone Rubber, and Class H components (rated for 180°C), offer better resistance to thermal aging. On the other hand, using recycled PVC, which lasts only about 6.3 years at 140°F compared to 30 years for new PVC, should be avoided to ensure durability.

Regular monitoring and maintenance are crucial for extending the lifespan of electrical insulation. Advanced techniques like thermal imaging, dielectric spectroscopy, and partial discharge detection can identify early signs of degradation, potentially increasing cable life by up to 40%. Tracking indicators like insulation resistance, dissipation factor (tan δ), and partial discharge levels helps determine when maintenance or replacement is necessary.

The quality of components also plays a significant role. Manufacturing defects, such as voids or cavities, create weak points that accelerate aging by enabling partial discharges. To ensure reliability and safety under thermal stress, sourcing components from trustworthy suppliers, such as Electrical Trader, is essential. Investing in high-quality materials and proactive care ensures long-term performance and reduces the risks associated with thermal aging.

FAQs

How can I tell if insulation is thermally aged before it fails?

To spot thermally aged insulation, keep an eye on its dielectric properties. Two key signs of aging include:

- Increased leakage current harmonics: This points to changes in the insulation's performance.

- Higher dielectric loss factor: Indicates a decline in the material's condition due to thermal stress.

By regularly monitoring these factors, you can catch early signs of degradation and take action to avoid potential failures.

Does the 10°C (18°F) rule apply to all insulation materials?

The 10°C (18°F) rule proposes that reducing the operating temperature by 10°C can approximately double the thermal lifespan of insulation. While this guideline is typically accurate for materials operating at their maximum continuous temperature rating, it is particularly relevant for systems like XLPE and similar polymers. However, it’s important to note that this rule doesn’t universally apply to all types of insulation.

Which tests best predict remaining insulation life in the field?

The best way to predict how much life insulation has left is by tracking diagnostic measurements over time. Key tests include dissipation factor, partial discharge, insulation resistance, and polarization index. These tests offer helpful data, but it’s important to note that no single test can give a definitive answer about insulation’s remaining lifespan.