Key Factors for Buying Medium Voltage Switchgear

Share

Looking for the right medium voltage switchgear? Here's what you need to know.

Medium voltage switchgear is critical for managing power distribution safely and reliably. It protects equipment, isolates faults quickly, and ensures smooth operations. But selecting the right one can be challenging. Here's a quick breakdown of the key factors to consider:

- Electrical Ratings: Ensure voltage, current, and fault ratings exceed your system's demands.

- Design Features: Choose between air, gas, or solid insulation, and prioritize safety features like arc-resistant designs.

- Compliance: Verify adherence to standards like IEEE C37.20.2 and NFPA 70 for safety and performance.

- Cost Analysis: Look beyond the upfront price - consider maintenance, lifespan, and total ownership costs.

- Environmental Factors: Account for site-specific conditions like temperature, altitude, and humidity.

Whether you're prioritizing safety, efficiency, or durability, understanding these factors will help you make an informed decision. Keep reading for a detailed guide to navigating your options and finding the best fit for your needs.

Medium-voltage switchgear fundamentals | Eaton PSEC

Electrical Specifications to Evaluate

Getting the electrical specifications right is crucial when choosing switchgear. These specs ensure the equipment can handle your system's demands safely and reliably. For instance, rated voltage ($U_r$) must exceed your system's maximum operating voltage ($U_{Nmax}$) to maintain proper insulation.

"The rated voltage is always higher than the systems operating voltage and determines the insulation levels of the equipment." – EEP

To put this into perspective, a 13.8 kV system would require a minimum rating of 15 kV.

The continuous current rating ($I_r$) specifies how much current the busbars and devices can handle without damage over time. Standard ratings range from 600 A to 4,000 A, assuming an ambient temperature of 104°F (40°C). If your site operates above this temperature, you'll need to account for derating or opt for switchgear with a higher current rating to prevent overheating of components like contacts and busbars. These parameters guide your decisions on voltage, current handling, and fault management capabilities.

Voltage and Current Ratings

When selecting the voltage class, it’s essential to align with your utility's system standards. ANSI/IEEE voltage classes like 5 kV, 15 kV, 27 kV, and 38 kV are typical benchmarks. Always choose the next higher standard to accommodate possible harmonics and voltage fluctuations.

Insulation levels are just as critical. The Basic Insulation Level (BIL), also known as the lightning impulse withstand voltage ($U_p$), must meet your utility’s requirements. For example, a 12 kV switchgear should withstand 28 kV rms at power frequency and 75 kV during lightning impulse events. Proper insulation ensures your system can handle faults and enhances its durability. If your installation is above 3,300 feet in elevation, keep in mind that thinner air reduces dielectric strength. In such cases, higher insulation levels or surge arresters are necessary.

Interrupting Capacity and Short-Circuit Withstand

The interrupting capacity of a circuit breaker is the maximum fault current it can safely interrupt, typically ranging from 25–63 kAIC for medium-voltage vacuum breakers. Meanwhile, the short-circuit withstand rating measures the structural strength of the assembly - how much current the busbars can endure without physical failure.

"The upstream switchgear must have a short circuit current rating that exceeds the worst-case currents that will be passing through the switchgear." – Eaton

Both ratings must exceed the worst-case fault current calculated for your installation. ANSI standards specify short-circuit withstand ratings from 25 kA to 63 kA symmetrical for a 2-second duration, with asymmetrical ratings reaching 40 kA to 101 kA for a 10-cycle rating. Additionally, the peak withstand current ($I_p$) for 60 Hz systems is generally 2.6 times the short-time withstand current ($I_k$). These specifications are vital to ensure the switchgear can handle extreme fault conditions without compromising safety or performance.

Design and Protection Features

Once you've confirmed the necessary electrical ratings, the next step is to evaluate the design and protection features of your switchgear. These elements are critical for ensuring safety, ease of maintenance, and overall reliability. Beyond the electrical specifications, the design features you choose will significantly impact operational efficiency and safety.

Insulation and Protection Types

The type of insulation medium plays a big role in determining the size and maintenance requirements of the equipment. Air insulation is a popular and cost-effective choice, but it requires more physical space due to its lower dielectric strength. On the other hand, gas-insulated switchgear (GIS), which uses SF6 gas, offers excellent dielectric properties and can reduce space requirements by up to 70% for systems operating at 30 kV. For environments that are harsh or have limited space, sealed-tank designs using gas or solid-dielectric insulation are a great option, as they eliminate the need for regular contact maintenance.

For medium-voltage applications, vacuum circuit breakers have become the go-to solution. These breakers extinguish arcs inside sealed vacuum bottles, ensuring quick fault clearance and reduced arc energy. Eaton highlights this benefit:

"The vacuum allows the arc to be extinguished quickly reducing the arc energy".

This technology not only handles higher voltage faults effectively but also achieves this within a compact footprint. For pad-mounted or subsurface installations, fluid insulation using fire-resistant materials like E200 or FR3 provides dual benefits of cooling and insulation.

Type Classifications and Accessibility Features

The type classification of switchgear enhances safety and serviceability, complementing the choice of insulation. Metal-clad switchgear (as per IEEE C37.20.2) provides a high level of safety by isolating the incoming bus, outgoing bus, instrumentation, and main breaker in separate metal compartments. This type is ideal for industrial and power generation facilities where isolation and ease of maintenance are priorities. Draw-out circuit breakers in these systems allow for quick replacements without disrupting the network.

In contrast, metal-enclosed switchgear (IEEE C37.20.3) uses shared compartments and supports both fixed and draw-out devices. This makes it a practical choice for commercial applications where space and budget are key considerations.

For enhanced safety during faults, arc-resistant designs certified by IEEE C37.20.7 are a must. These systems contain and redirect arc flash energy away from operators through a plenum. For example, Type 2B classifications provide full perimeter protection, even when the low-voltage control compartment doors are open. Remote racking systems further improve safety by enabling disconnect, test, and connect operations from 25 to 30 feet away.

When floor space is at a premium, front-accessible switchgear is a smart choice. Unlike traditional designs that need access from both the front and rear, these units can be installed directly against a wall, saving valuable space. For facilities where downtime is costly, specifying Loss of Service Continuity (LSC) 2B classification ensures access to the cable compartment without de-energizing the busbar or adjacent panels, allowing for maximum operational uptime.

Industry Standards and Compliance Requirements

Once you've selected your design and protection features, it's essential to ensure that your switchgear aligns with established industry standards. These standards validate that the equipment meets rigorous performance and safety benchmarks set by leading regulatory organizations. In the U.S., medium-voltage switchgear is governed by specific guidelines to assist buyers in making informed decisions.

ANSI, IEEE, and NFPA Standards

Medium-voltage switchgear standards primarily originate from IEEE (Institute of Electrical and Electronics Engineers) and ANSI (American National Standards Institute). Additionally, NFPA 70, also known as the National Electrical Code (NEC), provides the regulatory framework for proper installation. Together, these standards specify the types of equipment and their performance requirements.

- IEEE C37.20.2: This standard applies to metal-clad (MC) switchgear rated between 4.76 kV and 48.3 kV. It's particularly important for high-reliability applications in utility and industrial networks. A key feature of this standard is the requirement for full compartmentalization in MC switchgear. It also defines continuous main bus current ratings of 1,200 A, 2,000 A, 3,000 A, and 4,000 A, with the maximum voltage rating recently increased to 48.3 kV.

- IEEE C37.20.3: For applications where less isolation is needed, this standard governs metal-enclosed interrupter (MEI) switchgear. It covers assemblies rated above 1 kV up to 48.3 kV, including equipment like interrupter switches, selector switches, power fuses, and circuit breakers.

- IEEE C37.22: This standard outlines the preferred ratings and capabilities for indoor AC medium-voltage switches used in these assemblies. Ensuring compliance with the latest version, such as IEEE C37.20.2-2025, guarantees adherence to current voltage and safety protocols.

While IEEE and ANSI standards focus on equipment design and testing, NFPA 70 ensures safe installation practices. This combination of design and installation standards helps maintain both safety and reliability. Always request documentation confirming that the equipment meets these stringent testing requirements.

Standards Summary

Here’s a quick overview of the key standards:

| Standard | Equipment Type | Voltage Range | Primary Use |

|---|---|---|---|

| IEEE C37.20.2 | Metal-Clad (MC) Switchgear | 4.76 kV to 48.3 kV | High-reliability utility and industrial networks with full compartmentalization |

| IEEE C37.20.3 | Metal-Enclosed Interrupter (MEI) Switchgear | Above 1 kV to 48.3 kV | Distribution and protection with interrupter switches and fuses |

| IEEE C37.22 | Indoor AC Medium-Voltage Switches | N/A | Defines preferred ratings and capabilities for switches |

| NFPA 70 (NEC) | All Electrical Installations | N/A | Regulatory framework for safe electrical installation |

sbb-itb-501186b

Cost and Total Ownership Analysis

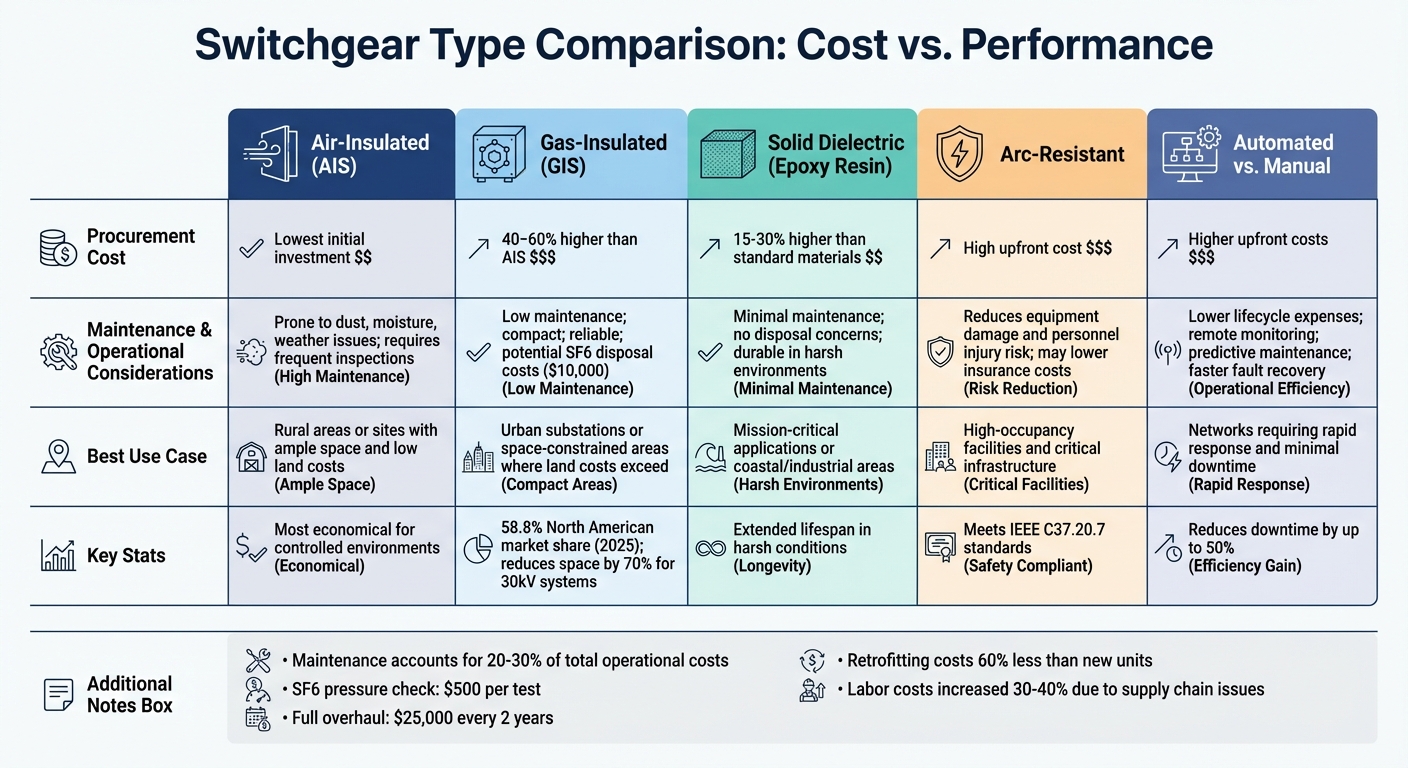

Medium Voltage Switchgear Types: Cost and Performance Comparison

When evaluating costs, it's essential to think beyond just the purchase price. The total cost of ownership includes everything from installation and maintenance to downtime and eventual disposal. As Jeff Turnbull, Global Product Manager at G&W Electric, explains:

"The true cost of ownership depends on a lot more than just the purchase price."

Upfront Costs and Market Trends

Several factors influence initial costs. System complexity and the number of circuits play significant roles, while the choice of insulation type also has a major impact. Air-insulated switchgear (AIS) generally offers the lowest entry price. On the other hand, gas-insulated switchgear (GIS), which accounted for 58.8% of the North American market share by 2025, costs 40–60% more due to its compact design and specialized materials. Additionally, automation and advanced relays can increase upfront costs but often reduce long-term operational expenses and downtime.

Supply chain issues have also pushed costs higher. For example, cast-resin prices have risen by 18%, and lead times for GIS equipment have doubled. Labor costs for commissioning have jumped 30–40%, with a 15 kV GIS now taking five weeks to commission instead of three. In urban areas, where land costs exceed $50 per square foot, GIS can actually become more cost-effective than AIS despite its higher equipment price. These factors underline the importance of considering the full range of expenses when comparing switchgear options.

Maintenance and Operational Costs

Maintenance can account for 20–30% of total operational costs. Manual systems require frequent inspections and interventions, while automated designs allow for predictive maintenance and remote monitoring. For instance, an SF6 pressure check costs around $500 per test, and a full overhaul can run about $25,000 every two years. Opting for resettable vacuum interrupters instead of traditional power fuses eliminates recurring replacement costs and enhances safety by avoiding manual fuse changes on energized equipment. However, SF6 disposal can add up to $10,000 to operational costs.

Retrofitting older equipment can be a cost-effective alternative. Replacing sensors or contacts in existing switchgear costs roughly 60% less than purchasing new units and can extend the equipment's service life by 10–15 years. For new installations, choosing designs with high ingress protection (IP68-rated) and corrosion-resistant materials can help prevent premature failures in harsh environments. These proactive measures can significantly improve system reliability and reduce long-term costs.

The North American medium voltage switchgear market, projected to reach $8.25 billion by 2026, is steadily moving toward SF6-free options like vacuum and fluoroketone insulation. These alternatives align with regulatory requirements, such as California's 2025 ban on SF6.

Comparison of Switchgear Types

Different switchgear designs come with their own cost and operational trade-offs. Understanding these differences helps you align your choice with both your budget and site requirements. Here's a breakdown to guide your decision-making:

| Switchgear Type | Procurement Cost | Maintenance & Operational Considerations | Best Use Case |

|---|---|---|---|

| Air-Insulated (AIS) | Lowest initial investment | Prone to dust, moisture, and weather issues; requires frequent inspections | Ideal for rural areas or sites with ample space and low land costs |

| Gas-Insulated (GIS) | 40–60% higher than AIS | Low maintenance; compact; reliable; potential SF6 disposal costs | Best for urban substations or space-constrained areas where land costs exceed $50/sq ft |

| Solid Dielectric (Epoxy Resin) | 15–30% higher than standard materials | Minimal maintenance; no disposal concerns; durable in harsh environments | Suitable for mission-critical applications or coastal/industrial areas |

| Arc-Resistant | High upfront cost | Reduces risk of equipment damage and personnel injury; may lower insurance costs | Designed for high-occupancy facilities and critical infrastructure |

| Automated vs. Manual | Higher upfront costs | Lower lifecycle expenses due to remote monitoring, predictive maintenance, and faster fault recovery | Ideal for networks requiring rapid response and minimal downtime |

"Automation often justifies its upfront cost through greater efficiency, faster recovery, lower maintenance expenses and fewer system disruptions." - Jeff Turnbull, Global Product Manager, G&W Electric

When comparing quotes, it's crucial to conduct a life cycle cost (LCC) analysis. This approach factors in acquisition, installation, training, maintenance, repairs, and even the cost of potential failures. While equipment with higher upfront costs might seem expensive, it often proves more economical over time, thanks to extended lifespans, reduced downtime, and lower maintenance needs.

Site and Environmental Factors

The environment where switchgear is installed plays a big role in how well it performs over time. One key factor is ambient temperature. Most standard ratings assume a maximum of 104°F (40°C). If temperatures regularly go above this, you’ll either need to reduce the equipment’s current-carrying capacity or add forced ventilation to manage the heat. Another often-overlooked factor is altitude. Standard insulation levels are designed for installations up to 3,300 feet (1,000 meters) above sea level. Beyond this height, thinner air reduces the insulating strength by about 9%, which means you may need equipment with higher voltage ratings or extra surge protection.

Humidity and condensation are also major concerns, especially in areas with fluctuating temperatures. Moisture can weaken insulation and even cause flashovers. To combat this, controlled heaters with humidistats can help prevent internal condensation. In coastal or industrial areas, environmental challenges like salt spray, corrosive gases, and dust can speed up component wear and tear. Gas-insulated switchgear (GIS) is a smart choice here since its sealed components are better protected from these contaminants. Electrical engineer Edvard Csanyi highlights this issue:

"It is also important to remember that protection, measurement, and control systems are more sensitive than switchgear, which is reason enough to ensure that the minimum requirements for air quality are observed".

Other environmental factors, like seismic activity and vibration, require reinforced designs and specialized mounting. In earthquake-prone areas, make sure your switchgear meets seismic certification standards. For indoor installations, check that the floor can handle the equipment’s weight, and ensure there’s enough space for access and operation. For outdoor switchgear, such as pad-mounted units, enclosures need to be weather-resistant (NEMA 3R or 4) and have proper IP ratings to guard against rain, dust, UV exposure, and even wildlife.

When it comes to space, the choice between air-insulated (AIS) and gas-insulated (GIS) switchgear often depends on site constraints. GIS is a great option for tight spaces, like urban substations or retrofits in existing buildings. On the other hand, if you have plenty of room and a controlled environment, AIS is usually more economical. Choosing switchgear that matches your site’s specific challenges not only helps avoid early failures but also ensures cost savings and reliable performance over the long term.

Finding Equipment on Electrical Trader

Once you've nailed down your electrical specifications, design features, standards, and budget, it's time to find the right equipment. Electrical Trader (https://electricaltrader.com) provides a one-stop marketplace for both new and used medium voltage switchgear. Its user-friendly filters make it simple to refine your search based on the technical specs you need.

You can filter listings by essential criteria like voltage and current ratings, short-circuit capacity, insulation type, and even enclosure types. For example, if you're working in outdoor or challenging environments, you can focus on NEMA-rated pad-mounted gear or indoor metal-clad assemblies to ensure the equipment meets necessary protection standards.

One standout feature of Electrical Trader is the ability to compare new and used equipment. Traditional procurement channels often come with frustrating lead times - 30 to 65 weeks for standard gear, and up to 80 weeks for more specialized components. Having access to quality used switchgear can significantly speed up replacements or expansions. This is especially important considering that the global medium voltage switchgear market is expected to hit around $39.33 billion by 2026, and over 70% of electrical system failures are tied to switchgear component issues.

When browsing, don't just focus on the upfront price. Consider the total cost of ownership (TCO). As Jeff Turnbull, Global Product Manager at G&W Electric, points out:

"The true cost of ownership depends on a lot more than just the purchase price. Reliability, maintenance, and how well the system holds up under pressure matter most".

Look for equipment equipped with intelligent electronic devices (IEDs) for remote monitoring and maintenance. These features can cut operational downtime by up to 50%. For used or refurbished options, check that listings include routine test reports to verify wiring and insulation integrity. This ensures you're investing in equipment that meets your technical needs while keeping lifetime expenses in check.

Another advantage of Electrical Trader is the ability to verify compliance with key standards like IEC 62271, ANSI, and IEEE. This ensures your equipment aligns with both international and local safety requirements. Whether you're working within a tight budget or need specialized configurations for utility networks, Electrical Trader's extensive selection and robust filtering tools make it easier to find switchgear that delivers on performance, cost-efficiency, and long-term reliability.

Conclusion

This guide highlights the importance of balancing technical requirements, safety considerations, and cost factors when selecting medium-voltage (MV) switchgear. It's crucial to confirm that electrical ratings exceed the system's demands, including the ability to handle fault currents. The fault current capacity should always surpass calculated levels to ensure reliable operation.

Choosing the right dielectric medium is equally important. Options include air for straightforward setups, gas for compact installations, or solid insulation for harsher environments. Incorporating arc-resistant designs that comply with ANSI/IEEE C37.20.7 standards, along with mechanical interlocks, significantly enhances operator safety. Additionally, automation can reduce downtime and maintenance expenses.

Adhering to standards like IEC 62271 or ANSI/IEEE C37.20.2 is essential. These certifications, backed by Type and Routine Test reports, ensure safety and reliability. Linsey Zhou of Eabel emphasizes:

"Standards and certifications help ensure MV switchgear is safe, reliable, and approved for use. They also make purchasing and inspection much easier".

Beyond compliance, evaluating long-term costs is a critical step. The total cost of ownership often exceeds the initial purchase price by 30% to 50% when considering installation, maintenance, and energy losses. While automated switchgear has a higher upfront cost, it reduces operational expenses through remote monitoring and quicker fault recovery. Investing in reliable equipment helps mitigate common failures and ensures smoother operations.

For a more efficient procurement process, Electrical Trader offers tools to simplify the search for MV switchgear. Their platform provides extensive filtering options, access to both new and used equipment, and ensures compliance with necessary standards. Whether you're constrained by budget or require custom configurations for demanding applications, their wide selection helps you find solutions that align with performance, cost-efficiency, and long-term reliability goals.

FAQs

What are the differences between air, gas, and solid insulation in medium voltage switchgear?

The differences between air, gas, and solid insulation in medium voltage switchgear come down to how they insulate, their maintenance requirements, and where they work best.

Air insulation uses the surrounding air as its insulating medium. It’s budget-friendly and often found in open-air substations. However, its performance can be affected by weather, dust, and temperature fluctuations, which may compromise reliability.

Gas insulation involves sealed enclosures filled with gases like SF6. This setup delivers excellent dielectric strength and allows for compact designs, making it perfect for tight spaces or high-voltage needs. On the downside, SF6 is a greenhouse gas, driving efforts to find greener alternatives.

Solid insulation relies on materials like epoxy resin. It’s known for being tough, requiring minimal upkeep, and standing up well to harsh conditions. This makes it a great choice for indoor or demanding environments, though it can be more expensive to produce.

Each type has its strengths: air insulation is affordable but weather-sensitive, gas insulation offers high performance in a compact form, and solid insulation combines durability with environmental benefits.

How do altitude and humidity impact the performance of medium voltage switchgear?

Altitude and humidity play a crucial role in the performance and safety of medium voltage switchgear. Here’s how these environmental factors come into play:

At higher altitudes, the air becomes less dense, which reduces its insulating properties. This makes the equipment more prone to electrical arcing or breakdowns. To counteract this, switchgear may need extra insulation or specific design adjustments to ensure safe and reliable operation in such conditions.

Humidity introduces another challenge. When paired with temperature fluctuations, it can lead to condensation forming inside the switchgear. This moisture can cause serious issues, like damaged insulation, corrosion, and even electrical faults. To address this, it’s important to choose equipment that’s tailored for the environment it will operate in. Proper installation, regular maintenance, and controlling indoor humidity levels are also key steps. Additionally, protective measures can help maintain the equipment’s performance and prolong its lifespan.

What factors should be included in the total cost of ownership for medium voltage switchgear?

When assessing the total cost of ownership for medium voltage switchgear, it’s crucial to think beyond just the initial price tag. Factors like maintenance costs, potential replacement needs, and the operational efficiency of the equipment throughout its lifespan play a big role in the overall expense.

You’ll also want to weigh other elements such as safety features, system reliability, and the impact on the environment. For instance, consider whether the switchgear uses SF6 gas or vacuum technology as its dielectric medium, as this choice can influence both environmental concerns and long-term costs.

Taking all these aspects into account helps ensure you’re making a decision that aligns upfront costs with long-term value and sustainability goals.