How Emergency Shutdown Systems Prevent Fires

Share

Emergency Shutdown Systems (ESDs) are critical for stopping electrical fires in industrial and commercial settings. These systems automatically cut power to equipment, isolate hazardous materials, and prevent small issues from escalating into major disasters. Unlike simple emergency stop buttons, ESDs manage facility-wide shutdowns in a controlled sequence, ensuring safety for people, equipment, and the environment.

Key Points:

- Purpose: ESDs prevent fires by cutting power to ignition sources and stopping hazardous fluid flow.

-

Types:

- EPO (Emergency Power Off): Simple manual switches for immediate power disconnection.

- EPSMS (Emergency Power Shutdown Management Systems): Advanced systems with programmable logic for controlled, automated shutdowns.

- Detection: Combines manual activation (e.g., EPO switches) and automatic detection (e.g., smoke and heat sensors).

- Main Components: EPO switches, shunt trip breakers, control panels, maintenance bypass switches, and undervoltage release devices.

- Regulations: U.S. standards like NFPA 70 and OSHA ensure proper installation and maintenance of ESD systems.

These systems reduce fire risks, protect facilities, and minimize costly downtime. Regular maintenance and compliance with safety regulations are essential for their reliability.

Emergency Power Shutdown Controls

What Are Emergency Shutdown Systems?

Emergency shutdown systems are advanced safety mechanisms designed to automatically cut electrical power to equipment during emergencies like fires. Unlike a basic emergency stop button that halts a single machine, these systems manage the shutdown of entire facilities. They disconnect power to IT equipment, HVAC systems, and UPS units, removing ignition sources and stopping electrical faults from escalating into fires. This goes far beyond the capabilities of a standard emergency stop mechanism.

As firealarm.com puts it, "An EPO switch reduces the danger posed by electrical fires and flooding during fire sprinkler activation". This feature is particularly important when fire suppression systems are triggered, as live electrical equipment can pose serious electrocution risks for emergency responders.

EPO and EPSMS Explained

Commercial and industrial facilities typically rely on two main types of emergency shutdown systems: Emergency Power Off (EPO) switches and Emergency Power Shutdown Management Systems (EPSMS).

- Emergency Power Off (EPO) switches are straightforward hardware devices, often recognized as the "Big Red Button." These switches provide immediate power disconnection, bypassing normal operating controls. When pressed, they activate shunt trip breakers using control voltage (24VDC or 120VAC) to disconnect power circuits.

- Emergency Power Shutdown Management Systems (EPSMS) are more sophisticated. They use centralized programmable logic to manage shutdowns in a controlled sequence. As Suppression Systems, Inc. explains, "SSI's Emergency Power Shutdown Management System replaces basic EPO hardware with intelligent, logic-controlled protection that prevents unintended shutdowns while maintaining true emergency control". EPSMS systems allow for orderly shutdowns, separate controls for different equipment types, and real-time monitoring of breaker status. One key feature is their power-on trip logic, which ensures shutdowns only occur when active voltage is detected - minimizing false trips from power loss or wiring issues.

The difference between these systems has a big impact on facility operations. While EPO switches offer a simple solution, they can be accidentally triggered, leading to unnecessary downtime. EPSMS, on the other hand, provides a smarter, more reliable approach, reducing restart times and improving maintenance efficiency. This matters because the average cost of a single data center outage is nearly $700,000.

How These Systems Detect and Stop Electrical Fires

Emergency shutdown systems use both manual and automatic methods to detect and respond to electrical fires.

- Manual activation involves EPO switches placed near room exits, allowing quick power cuts when smoke, flames, or other fire indicators are noticed. To prevent accidental activations - which can severely disrupt operations - modern systems include features like recessed buttons, alarmed covers, or two-step "A/B" confirmation logic.

- Automatic detection integrates with fire alarm systems, smoke detectors, and heat sensors installed throughout the facility. When these sensors detect fire conditions, they send signals to the shutdown system, which then executes a coordinated power-off sequence. This ensures that electrical hazards are addressed before or during fire suppression system activation, helping to prevent the spread of electrical fires and protecting equipment and personnel.

Main Components of Emergency Shutdown Systems

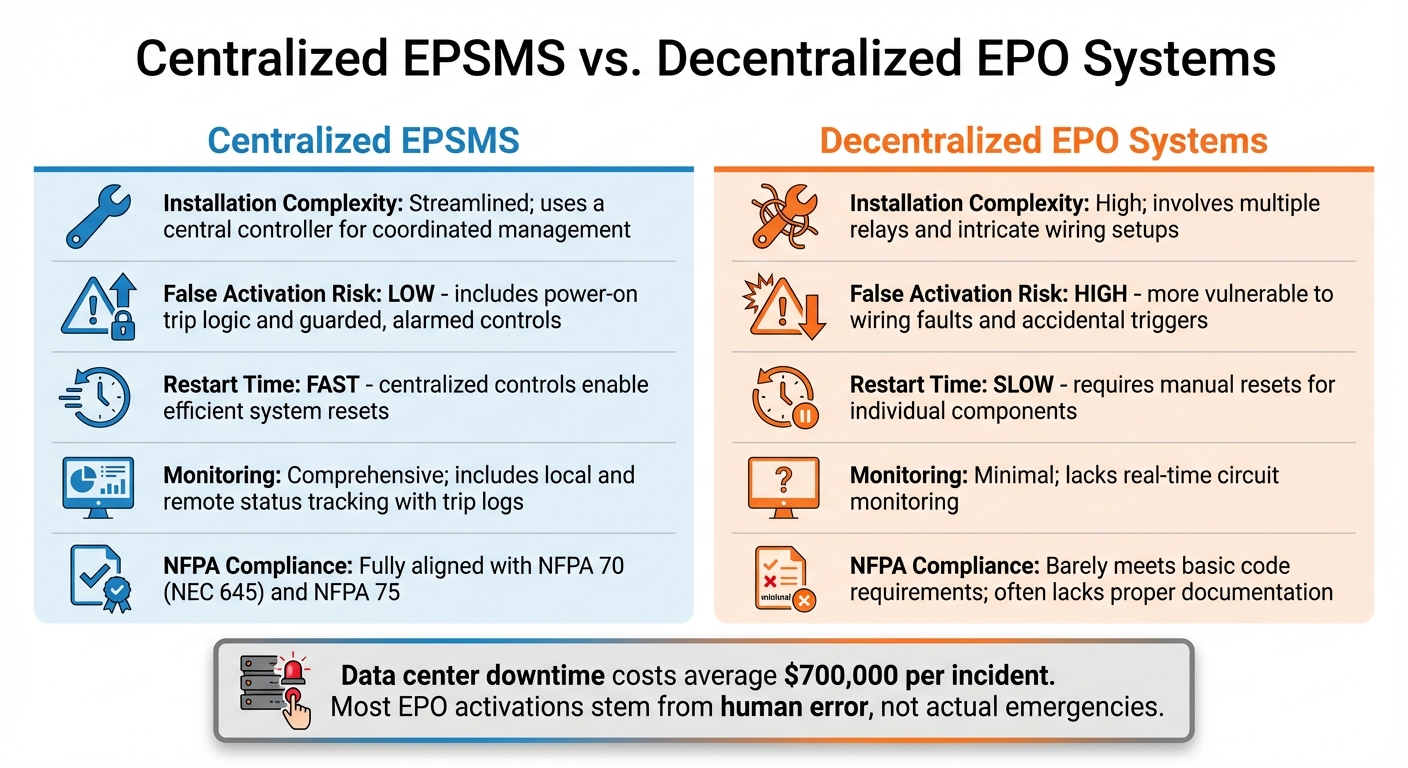

Centralized EPSMS vs Decentralized EPO Systems Comparison

Core System Components

Emergency shutdown systems are designed to immediately cut off power in emergencies, such as fires, to protect both people and infrastructure. These systems rely on several key components to ensure a quick and reliable response.

EPO (Emergency Power Off) switches act as a manual override, allowing users to disconnect power without relying on standard controls. These switches are connected to shunt trip breakers, which use control voltage to remotely interrupt power circuits.

Control panels play a central role by managing disconnect operations, monitoring breaker status in real time, and employing logic-based protections to avoid accidental shutdowns. Additionally, they generate trip log reports, which help facility managers review system performance after an event. This provides critical insights into system health, both locally and remotely.

Maintenance bypass switches enable technicians to test the system without triggering a full shutdown. These switches often include lock-out features to prevent unintentional activation during maintenance. Other essential components include clearing contacts, which protect shunt trip coils during extended power-off periods, and undervoltage release (UVR) devices, which automatically trip circuits during prolonged power losses.

"In an emergency, firefighters will use the EPO as a quick way to ensure others will not be exposed to dangerous voltages and eliminate electricity as a source of ignition." – Danny Chisholm, Technical Committee Member, NFPA 99, 110, and 111

Centralized EPSMS vs. Decentralized EPO Systems

The design of an emergency shutdown system significantly affects its functionality and reliability. Comparing centralized and decentralized architectures highlights these differences.

Decentralized EPO systems are simpler setups, typically built with relays and shunt-trip breakers. However, they often lack integrated monitoring and are prone to wiring complexities. On the other hand, centralized Emergency Power Shutdown Management Systems (EPSMS) use a central controller with intelligent, logic-driven protection. This allows for coordinated shutdowns and selective control, such as isolating HVAC systems while keeping IT equipment unaffected.

| Feature | Centralized EPSMS | Decentralized EPO Systems |

|---|---|---|

| Installation Complexity | Streamlined; uses a central controller for coordinated management | High; involves multiple relays and intricate wiring setups |

| False Activation Risk | Low; includes power-on trip logic and guarded, alarmed controls | High; more vulnerable to wiring faults and accidental triggers |

| Restart Time | Fast; centralized controls enable efficient system resets | Slow; requires manual resets for individual components |

| Monitoring | Comprehensive; includes local and remote status tracking with trip logs | Minimal; lacks real-time circuit monitoring |

| NFPA Compliance | Fully aligned with NFPA 70 (NEC 645) and NFPA 75 | Barely meets basic code requirements; often lacks proper documentation |

The financial implications of choosing the right system are significant. Data center downtime costs an average of nearly $700,000 per incident, and most EPO activations stem from human error rather than actual emergencies. As a result, selecting the right architecture can have a major impact on both safety and operational expenses.

sbb-itb-501186b

U.S. Regulatory Standards for Emergency Shutdown Systems

NFPA Requirements for Electrical Fire Prevention

In the U.S., strict regulatory standards ensure that emergency shutdown systems are designed for quick and dependable fire prevention. These regulations focus on maintaining power for critical fire detection and protection systems while enabling swift disconnection during emergencies.

The NFPA 70 (National Electrical Code), particularly Article 700, forms the backbone of these requirements. This section governs emergency systems that must automatically supply power to essential equipment like fire detection systems, alarms, and fire pumps. These systems are classified and mandated by the authority having jurisdiction.

"Emergency systems are classed as such, and thus required, by a governmental agency having jurisdiction [Art. 100]. These automatically supply illumination and/or power essential for preserving human life." – Mike Holt, NEC Expert

The code also specifies that Emergency Power Off (EPO) systems must have shutdown buttons located near IT equipment entrances. This placement allows responders to quickly cut power during a fire, reducing risks to both individuals and valuable equipment. At the same time, the code ensures power continuity for essential fire safety tools like detection and suppression systems, ensuring they function when needed most.

Beyond the NEC, OSHA regulations under 29 CFR 1910.164 add further detail to the installation and upkeep of fire detection and shutdown systems. These rules require systems to be securely mounted, protected from damage, and approved for use. OSHA also mandates that alarms triggered by fire detectors cannot be delayed by more than 30 seconds unless necessary for safety, such as allowing evacuation time before activating gas suppression systems. Maintenance, testing, and servicing of these systems must be carried out by qualified personnel to ensure they remain operational during emergencies.

For high-risk environments, additional measures are outlined by NIST guidelines. For instance, NIST SP 800-53 (PE-10) requires emergency shutoff capabilities in areas like data centers, server rooms, and locations housing computer-controlled machinery. These shutoff switches must be carefully positioned to allow authorized access while preventing accidental or unauthorized use.

Together, these regulations and guidelines create a robust framework to protect lives, equipment, and facilities during fire emergencies.

How to Install and Maintain Emergency Shutdown Systems

Installation Steps

When setting up an Emergency Power Shutdown Management System (EPSMS), it's best to opt for a centralized system instead of decentralized relay setups. Centralized systems make it easier to monitor, maintain, and expand when needed. Install control panels inside NEMA 1 enclosures with hinged doors, and choose either flush or surface mounting based on your facility's layout.

For wiring, connect actuation stations in parallel to ensure redundancy. Keep conductor lengths under 10 feet and avoid sharp 90° bends to maintain system integrity. Integrate the EPSMS with the fire alarm control panel to enable coordinated shutdowns during emergencies.

To prevent accidental activation, install safety features like locking-type switches with hinged or alarmed covers. Add clear signage near all Emergency Power Off (EPO) switches, which should be positioned near room exits in compliance with NEC standards. Use power-on trip logic to avoid false shutdowns caused by simple power outages, and include clearing contacts to protect shunt trip coils from damage.

Document every circuit, valve, and operation sequence with detailed drawings and labels for easy reference. Finally, test the system thoroughly to ensure it responds correctly during shutdowns without causing any unintended disruptions.

Maintenance and Testing Procedures

Proper maintenance and regular testing are key to keeping your emergency shutdown system reliable over time. Once installed, these systems require consistent oversight to ensure they perform as intended.

Annual inspections are required by OSHA regulations. Fixed extinguishing systems and related shutdown mechanisms must be checked at least once a year to confirm they're in good working condition. For refillable storage containers, inspect their weight and pressure every six months. If you detect a loss of more than 5% in net content or a pressure drop exceeding 10%, immediate maintenance is necessary.

Routine testing is essential for reliability. Conduct emergency response drills on a quarterly basis to ensure the system operates as expected during real emergencies. Regularly test bypass switches and relays to confirm they function properly. Use maintenance override switches with lock-out features to allow servicing without triggering a full system shutdown. If the system needs to be taken offline for repairs, establish a temporary fire watch and notify the fire department within 30 minutes.

Keep spare parts, such as detection devices and other critical components, on-site for quick restoration after an activation event. Periodically clean detectors to remove dust and dirt, which can reduce sensitivity or trigger false alarms. Annually review training for all personnel responsible for inspecting, maintaining, or repairing these systems to ensure they remain proficient in their duties. Lastly, maintain detailed records of semi-annual container checks and annual inspections for the entire lifespan of the system or until the next scheduled check.

Conclusion

Emergency shutdown systems serve as a crucial safety mechanism, safeguarding people, equipment, and facilities from the dangers of electrical fires. These systems work by automatically disconnecting electrical equipment from power sources and initiating an orderly shutdown, effectively preventing ignition sources from spreading. They also help lower internal pressure, reducing risks to personnel and minimizing damage to equipment.

"Emergency power controls are an extremely vital part of a complete fire safety system." – Firealarm.com

Modern centralized management systems provide better protection compared to older decentralized models. They offer real-time monitoring, faster restarts, and help reduce costly downtime, which can average nearly $700,000 per incident. Additionally, Programmable Logic Controllers (PLCs) continuously monitor safety parameters and perform diagnostics, significantly lowering the chances of hazardous failures. This level of performance is essential for meeting the rigorous safety requirements set by U.S. standards.

U.S. regulations, such as NFPA 70 and NFPA 75, play a key role in ensuring safe operations. These systems, when integrated with fire suppression equipment, can cut power before or during the release of suppression agents.

Long-term reliability and fire prevention depend on regular maintenance, proper installation, and routine inspections. Consistent upkeep is critical for sustained performance and safety.

For more information on enhancing your system's safety or exploring premium electrical safety components, visit Electrical Trader.

FAQs

What’s the difference between an Emergency Power Off (EPO) system and an Emergency Power Shutdown Management System (EPSMS)?

The key distinction between Emergency Power Off (EPO) systems and Emergency Power Shutdown Management Systems (EPSMS) lies in their level of complexity and scope of functionality.

An EPO system is a basic safety mechanism designed to immediately cut power to specific equipment or areas during emergencies such as fires, electrical malfunctions, or flooding. It’s typically triggered either manually or automatically and is primarily focused on delivering a fast, straightforward response to protect both people and equipment.

In contrast, an EPSMS takes things further by offering a centralized and integrated approach to power shutdown management. These systems combine multiple shutdown controls into a single management platform, reducing risks like unintentional activation. They often include advanced features like logic controls, centralized control panels, and maintenance bypass options. Built for high-stakes environments, EPSMS ensures adherence to safety standards such as NFPA 70 and NFPA 75, providing a more reliable and comprehensive solution for emergency power management.

In essence, while EPO systems are simple and designed for quick, isolated shutdowns, EPSMS delivers a coordinated, feature-rich approach to handling emergency power scenarios with greater efficiency and precision.

How do emergency shutdown systems work with fire alarm systems to prevent fires?

Emergency shutdown systems (ESDs) are designed to work hand-in-hand with fire alarm systems, adding an extra layer of safety to help prevent fires. When a fire alarm detects a potential threat, it can trigger the ESD to automatically shut down electrical equipment or processes. This swift action helps reduce the chance of electrical fires caused by issues like short circuits or equipment failures.

By cutting off power, isolating dangerous areas, or even activating fire suppression systems, ESDs play a critical role in containing fires and safeguarding both people and property. This kind of coordination is especially crucial in high-risk settings like industrial plants or data centers, where quick responses can mean the difference between minor incidents and major disasters.

What maintenance is needed to keep emergency shutdown systems reliable?

To keep emergency shutdown (ESD) systems dependable, regular upkeep is non-negotiable. This means routinely inspecting and testing critical components like control panels, sensors, relays, and actuators to ensure they're functioning correctly and to identify any potential problems before they escalate.

Maintenance should also include checking the condition of wiring, confirming the performance of safety devices such as pressure switches and gas sensors, and verifying that control systems are operating as they should. Adhering to industry standards, like those outlined in NFPA guidelines, is key, along with meticulously documenting all maintenance activities. Regular calibration and testing are vital steps to ensure the system is always ready to effectively mitigate risks like fires and other hazards.