Dynamic Power Factor Correction Panels: Buying Guide

Share

Dynamic Power Factor Correction (DPFC) panels are designed to improve energy efficiency, reduce costs, and protect equipment in facilities with fluctuating electrical loads. These panels use thyristor-based switching for fast response times (under 20 ms), minimizing voltage transients and extending equipment lifespan. They align voltage and current waveforms to improve the power factor, often saving industrial facilities up to 15% in energy consumption.

Key features include:

- Switching Technologies: Thyristor-based systems for fast load adjustments, IGBT-based systems for harmonic filtering, and hybrid systems combining both.

- Automation: Digital controllers maintain power factors up to 0.99, with advanced options reducing harmonic distortion to less than 3%.

- Safety Standards: Panels comply with IEC standards and include protections like overvoltage safeguards and MCCBs.

When choosing a panel, consider your facility's load profile, harmonic content, and installation environment. For dynamic loads like welding or elevators, thyristor or hybrid panels are ideal. Proper installation and maintenance ensure long-term reliability and cost savings.

Quick Tip: Conduct an energy audit before purchasing to optimize panel selection and ensure maximum efficiency.

Key Features and Technologies

Switching Technologies

The type of switching technology used plays a big role in how quickly systems can respond to load changes. Thyristor-based systems, which rely on SCRs (Silicon Controlled Rectifiers), offer zero-current switching. This means they can adjust instantly to load variations without causing voltage transients. These systems are commonly rated between 50 kVAR and 600 kVAR for 3-phase 415 V applications. Plus, with no moving parts, they tend to last longer.

On the other hand, IGBT-based technology, used in Static Var Generators (SVG) or Active Power Factor Correction (PFC) systems, provides smooth, stepless compensation for both leading and lagging power factors. Active PFC circuits are highly efficient, achieving over 97% efficiency and maintaining a power factor above 0.99. These systems are especially effective in environments with high harmonic distortion, as they actively filter out harmonics while correcting the power factor.

Hybrid systems take the best of both worlds by combining thyristor-switched capacitor banks with IGBT-based SVG modules. The capacitors manage bulk reactive power, while the SVG fine-tunes adjustments. This combination offers both precision and cost savings. For facilities with rapidly changing loads, like those in welding or elevators, thyristor or hybrid panels are ideal, as they eliminate switching transients.

These advanced switching technologies integrate seamlessly with digital control systems, enabling precise and efficient adjustments.

Automation and Control Systems

Modern systems use digital controllers to manage power factors automatically. These controllers monitor the phase angle between voltage and current and adjust capacitor banks in multiple stages - usually 4, 6, or 8 stages - based on the reactive load. Using the VAR sensing principle, they maintain a target power factor of up to 0.99 lag. For more complex, non-linear loads, advanced controllers with DSP algorithms can reduce Total Harmonic Distortion (THD) to less than 3%.

To enhance oversight and maintenance, these systems often support communication protocols like Modbus RTU/TCP, Profinet, and Ethernet/IP, allowing integration with SCADA and Building Management Systems. Human-Machine Interfaces (HMI) and multifunction meters provide real-time data on parameters like voltage, amperage, power factor, kW, kWh, and THD-V/I. Built-in protections guard against risks such as overvoltage, undervoltage, overheating, and unbalanced loads.

A well-designed automated system can deliver a return on investment in as little as two years. Additionally, facilities that optimize their power factor to around 0.95 can reduce the strain on local grids by approximately 18%.

Enclosure and Safety Standards

The safety and durability of these systems rely heavily on their enclosures and adherence to industry standards.

Capacitors are built to meet IEC 60831-1/2 standards for self-healing shunt power capacitors and IEC 60871-1/2 standards for shunt capacitors in AC systems. Switchboards must comply with IEC 61439 Part 2. Dry-type, self-healing capacitors with over-pressure disconnection are commonly used to minimize fire risks and equipment damage in case of faults.

For overcurrent protection, panels typically include an incoming Molded Case Circuit Breaker (MCCB) with ratings between 250 A and 630 A, which also serves as the primary isolation point. Standard panel dimensions are about 67 inches high, 24 inches wide, and 24 inches deep (1,700 mm × 600 mm × 600 mm). However, ensuring sufficient clearance for cooling and maintenance is essential. In challenging environments, such as data centers or hospitals, specialized designs like the Schneider Electric AccuSine PCSn are built to handle demanding conditions.

sbb-itb-501186b

Factors to Consider When Purchasing

Load Profile and Application

The first step in selecting the right panel is understanding your facility's load characteristics. For facilities with constant demand, fixed capacitors are a good fit, while switched units are better for variable loads. If you're dealing with large motors, assign individual capacitors to each one. For smaller motors, grouping them at a central distribution point can simplify the setup.

Another crucial element is evaluating harmonic content caused by non-linear devices. This will help you decide whether to add detuned reactors or active harmonic filters to control distortion. For dynamic loads with rapidly changing requirements, like welding equipment or elevators, consider thyristor-based switching or Electronic VAR Control. These options provide fast, resonance-free compensation. As a general guideline, capacitor banks are sized at 25% to 40% of the transformer's capacity. For instance, a 1,000 kVA transformer would typically need 250 kVAR to 400 kVAR of compensation.

Before making a final decision, conduct an energy audit to confirm that power factor correction is the right solution. This audit can also identify outdated equipment that might be wasting energy. For complex systems, opt for controllers with 4-quadrant measurement capabilities to ensure accurate reactive power management in all conditions. In commercial setups with many single-phase non-linear loads, make sure the system can handle neutral harmonic currents effectively.

Lastly, evaluate the installation environment to maximize both performance and lifespan.

Installation Environment

The environment where the panel will be installed plays a significant role in its performance and durability. Panels should be equipped with proper cross-ventilation, using louvers or fans, to manage the heat generated - especially when reactors and filters are included. To prevent overheating, maintain a minimum gap of 25–30 mm between individual capacitors and at least 50 mm between the capacitors and the panel enclosure.

If the setup includes detuned filters or operates in high-temperature conditions, active cooling fans are a must. Capacitors should always be mounted vertically for safe and efficient operation, so confirm that your installation site can accommodate this orientation. When banking capacitors, maintain a minimum gap of 25 mm between phases and 19 mm between phases and the ground for proper electrical insulation. For safety, always wait at least 60 seconds after turning off the power supply before handling or maintaining the capacitors, allowing them to discharge fully.

Lastly, think ahead about scalability and maintenance to ensure the system remains efficient and adaptable over time.

Scalability and Maintenance

For systems that might need future expansion, modular designs are a practical choice. They simplify scaling and help keep maintenance costs manageable. Modular systems, such as those using interleaved boost converters, make it easier to expand high-power setups. When sizing capacitor units, aim for 125% of the reactive load, and plan for regular servicing - ranging from quarterly to annually - depending on the system's importance.

Choose panels with built-in fault logging via microprocessors or PLCs. These features can identify issues early, reducing downtime. Install capacitor banks as close as possible to major inductive loads to minimize line losses. For short-circuit protection, use MCCBs rated at no more than 1.8 times the capacitor's rated current, particularly when working with detuned filter banks.

Automatic Power Factor Correction: A Practical Training Course

Comparison of Panel Types and Specifications

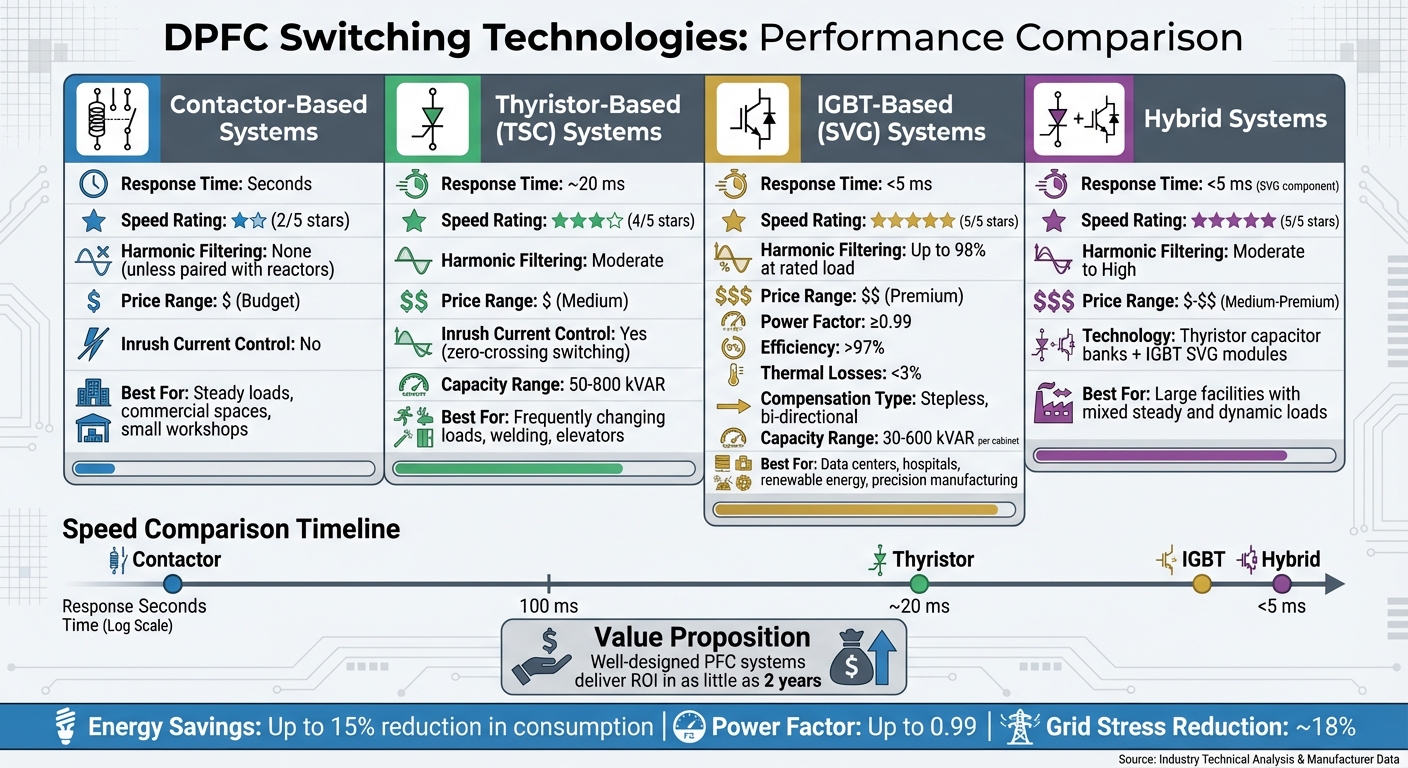

Dynamic Power Factor Correction Panel Switching Technologies Comparison Chart

This section delves into how different panel types and switching technologies stack up, helping you align system choices with your facility's needs.

Switching Technology Comparison

Switching technologies play a crucial role in determining a system's speed, efficiency, and overall suitability for specific applications.

- Contactor-based systems: These systems respond within seconds, making them a practical choice for steady loads like those in commercial spaces or small workshops. However, they lack harmonic filtering unless paired with additional reactors.

- Thyristor-based (TSC) systems: With a response time of about 20 ms, TSC systems offer better performance. They switch at the zero-crossing point of the voltage waveform, effectively eliminating inrush currents and transients. These systems are often found in the medium price range.

- IGBT-based systems (Static Var Generators, SVG): Positioned at the premium end, SVGs deliver incredibly fast response times - under 5 ms. Unlike traditional capacitor banks, they provide stepless, bi-directional compensation and can filter up to 98% of harmonics at rated load.

As ZDDQ Electric explains, "Static var generator (SVG) is currently the best solution in dynamic power factor correction field... the regulation speed of SVG is faster (the response speed is within 5ms)".

These systems maintain a power factor of 0.99 or higher and have thermal losses of less than 3%. Their advanced capabilities make them ideal for demanding applications such as data centers, renewable energy setups, and precision manufacturing.

- Hybrid systems: By combining traditional capacitor banks with SVG modules, hybrid systems offer a balanced approach. They achieve fast response times (under 5 ms for the SVG component) and moderate harmonic filtering. These systems are particularly effective for large facilities with a mix of steady and dynamic loads, bridging the cost gap between thyristor-based and full SVG systems.

Switching technologies set the stage for performance, but panel configurations further refine system capabilities to meet specific operational needs.

Panel Type Comparison

Panel configurations directly influence system performance and costs, making it essential to choose wisely based on application requirements.

- Standard APFC panels: These panels, with capacities ranging from 50 to over 1,000 kVAR, use stepped mechanical contactors to respond within 1 to 60 seconds. Priced between $3,900 and $4,930 (excluding taxes), they are well-suited for predictable loads in environments like general manufacturing and HVAC systems.

- Dynamic TSC panels: Offering capacities from 50 to 800 kVAR, these panels respond in under 20 ms. Their zero-crossing switching eliminates transients, making them a strong option for facilities with frequently changing loads.

- Static Var Generators (SVG): Operating in the 30 to 600 kVAR range per cabinet, SVGs deliver the fastest response times - under 5 ms. They offer stepless, bi-directional compensation and are designed to tackle harmonic resonance. These features make them a top choice for hospitals, microgrids, and renewable energy installations. Modern SVG systems boast efficiency ratings of 97% or higher and can scale up to 10 racks in parallel configurations.

Sourcing Panels with Electrical Trader

Once you’ve nailed down the panel specifications, the next step is finding the right equipment. That’s where Electrical Trader’s marketplace comes in.

Product Categories and Options

Electrical Trader’s platform features Automatic Power Factor Correction (APFC) Panels, which automatically adjust capacitor banks to maintain a near-unity power factor. For added protection, they offer detuned panels with reactors (available in 5.67%, 7%, or 14% detuning) to safeguard capacitors from potential failures.

If you’re looking for cutting-edge solutions, they also have Static Var Generators (SVG/STATCOM) and hybrid systems designed for real-time, high-speed compensation. Whether you need brand-new equipment or are open to used options, the marketplace caters to a variety of capacities, ensuring flexibility for different operational needs.

Benefits of Buying from Electrical Trader

Electrical Trader brings more to the table than just a wide product selection - it streamlines the entire procurement process. The platform features global brands like ABB, Schneider, EPCOS, and L&T, along with a vast inventory that includes everything from breakers to transformers.

Navigating the platform is simple, with categorized listings and featured collections that make browsing easy. Whether you’re an electrician, facility manager, or end-user, you can compare new and used equipment in one centralized place. This setup helps buyers find solutions tailored to their specific needs, from steady industrial loads suited for contactor-based systems to dynamic applications requiring thyristor switching - all at competitive prices.

What sets Electrical Trader apart is its focus on quality and reliability. Panels sourced through the platform comply with ISO and IEC standards and undergo factory testing before delivery. Many panels also come equipped with multifunctional LCD displays, offering real-time data on voltage, reactive power (kVAR), active power (kW), and harmonics (3rd to 19th), giving buyers the tools to monitor performance with precision.

Conclusion

Choosing the right dynamic power factor correction (PFC) panel means matching its technical features to your facility's specific load requirements. Thyristor-based switching is a smart option for fast-changing loads, as it eliminates voltage transients and extends the lifespan of capacitors. For environments with non-linear equipment like VFDs or UPS systems, incorporating detuned reactors is key to avoiding resonance and protecting your system.

A well-designed PFC system offers a quick return on investment, often within two years. Facilities can save up to $740,000 annually by reducing excessive reactive power draw. Improving the power factor to 0.95 not only eases grid stress by about 18%, but also slashes wasted reactive power by 60% to 80%.

Before committing to a PFC system, it’s important to conduct a professional energy audit. This will confirm whether PFC is the right solution and may uncover other opportunities to enhance energy efficiency. When sizing capacitors, aim for around 125% of your calculated reactive power needs, and prioritize regular maintenance to avoid penalties.

Installation matters just as much as selecting the right equipment. Place capacitor banks near major inductive loads, ensure proper ventilation, and verify discharge delays before reactivating. Additionally, ensure that panels meet IEC standards to guarantee both safety and reliability.

FAQs

How do I choose between TSC, SVG, and hybrid PFC panels?

To decide between TSC, SVG, and hybrid power factor correction (PFC) panels, think about your specific application, the nature of your load, and how quickly your system needs to respond.

- TSC panels are perfect for managing rapid load changes, making them a great fit for industries with fluctuating loads.

- SVG panels excel in delivering precise reactive power management, especially in networks with significant harmonic distortion.

- Hybrid panels blend the benefits of both, offering a balance of cost, adaptability, and efficiency.

Ultimately, the right choice depends on your system’s requirements, how dynamic your loads are, and your budget constraints.

Do I need detuned reactors or active harmonic filtering?

Detuned reactors play a critical role in environments with high harmonic levels, as they help prevent overvoltage and resonance problems when used alongside power factor correction capacitors. Meanwhile, active harmonic filters are designed to minimize harmonic distortion, improving the overall quality of power in the system. Choosing between these solutions depends on the harmonic levels present in your setup and the improvements you're aiming to achieve in power quality.

What kVAR size should I buy for my facility?

To determine the correct kVAR size, you need to consider your load, current power factor, and the desired power factor. You can calculate the required reactive power (kVAR) using specific formulas or tools. Alternatively, reviewing your utility bill can provide insights into your existing load and power factor. This approach ensures the correction panel is tailored to meet your facility's specific requirements.