How Alternator Size Impacts Efficiency

Share

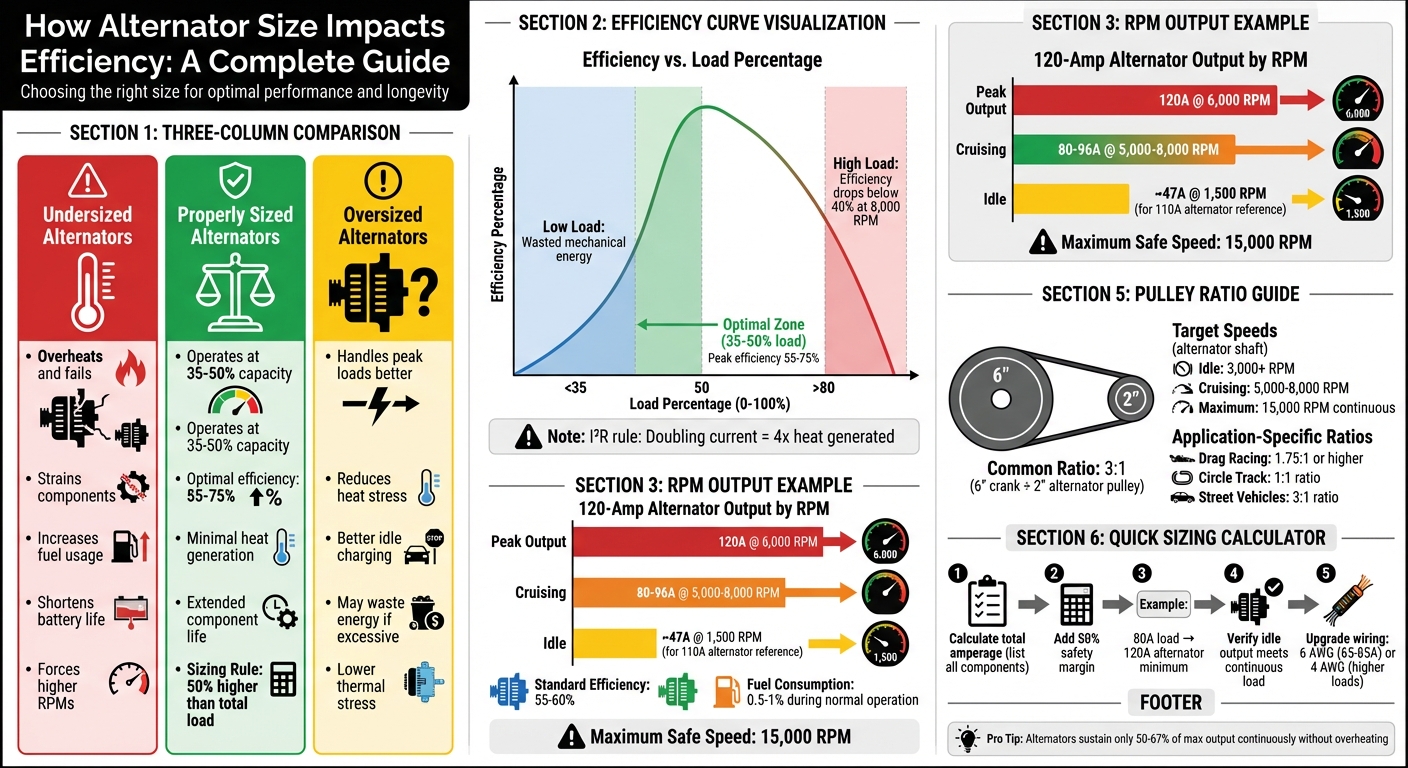

Choosing the right alternator size is critical for efficient system performance, reduced fuel consumption, and prolonged component lifespan. Here's the main takeaway: an alternator that's too small can overheat and fail, while one that's too large wastes energy if underutilized. Proper sizing ensures optimal efficiency and reliability.

Key Points:

- Undersized Alternators: Overheat, strain components, increase fuel usage, and shorten battery life.

- Oversized Alternators: Handle peak loads better, reduce heat, and extend component life but may waste energy if oversized excessively.

- Efficiency Range: Alternators operate best at 35%-50% of their rated capacity. Efficiency drops significantly at low or high loads.

- RPM Dependency: Alternator output is tied to engine speed. For example, a 120-amp alternator achieves peak output at 6,000 RPM but drops significantly at idle.

- Sizing Tip: Choose an alternator rated 50% higher than your total electrical load to handle spikes and future upgrades.

- Pulley Ratios: Affect alternator speed and output. A 3:1 ratio is common but should match your engine's RPM limits.

By understanding these factors, you can select an alternator that balances efficiency, durability, and performance.

Alternator Sizing Guide: Efficiency Ranges and Performance Comparison

How to Choose a High-Amp Alternator

sbb-itb-501186b

How Alternator Size Affects Efficiency

Alternator efficiency depends on how much of its capacity is being used. Standard automotive alternators typically operate at an efficiency of 55% to 60%, while high-efficiency models can reach 68% to 75%. The difference comes down to design - high-efficiency alternators use windings with higher density, which helps reduce resistive losses and heat buildup.

For best performance, alternators should run at 35% to 50% of their rated capacity. Operating outside this range - either too low or too high - causes efficiency to drop. When pushed to high RPMs (around 8,000), efficiency can fall below 40% due to increased heat and resistance. Coy Hudnall from Powermaster Motorsports explains:

Alternators lose about 10 percent of their output capability when they move from room temperature up to operating temperature.

Another source of inefficiency comes from the rectifier. In a 14V system, diodes typically cause a voltage drop of 1.2V to 2V, resulting in a power loss of around 12.5%.

Alternator Efficiency Curves Explained

Each alternator has an efficiency curve that shows how well it converts mechanical energy into electrical power under different loads. The most efficient range is between 35% and 50% of its capacity. Within this range, the alternator generates sufficient power without excessive heat or resistance losses. Outside this range, efficiency declines sharply.

At low loads, mechanical energy is wasted, while at maximum capacity, resistive losses increase exponentially due to the I²R rule - doubling the current quadruples the heat generated. This extra heat raises coil resistance, further reducing output. High temperatures also damage components like bearings, brushes, and rectifiers, making temperature management critical under heavy loads.

Larger alternators handle these challenges better. They generate less heat when producing the same output as smaller units because they’re not operating at their limits. This advantage extends the life of internal components and ensures consistent performance.

Problems with Undersized Alternators

Using an undersized alternator can lead to a range of issues. If the alternator can’t meet the system’s demand, it draws power from the battery, causing voltage drops. This can lead to dim lights, sluggish fans, or even engine stumbles at low RPMs. While alternators typically consume 0.5%–1% of a truck’s fuel during normal operation, an overworked alternator forces the engine to work harder, increasing fuel consumption.

Mechanical strain is another concern. Undersized alternators often need higher RPMs to meet demand, which puts extra stress on bearings, belts, and the engine. This constant strain can lead to premature component failure. As AutoZone notes:

High electrical loads can cause the alternator to overheat and eventually fail.

Additionally, frequent deep cycling in these situations can shorten the battery’s lifespan. Oversizing the alternator can help address many of these problems.

Benefits of Oversized Alternators

Oversizing an alternator - when done moderately - can provide several advantages. Linz Electric advises:

Slightly oversizing the alternator compared to the engine's rated power to optimize response to transients and ensure better voltage stability.

By operating within its optimal efficiency range, an oversized alternator generates less heat and lasts longer. It also charges the battery more effectively at idle, ensuring it stays at least 80% charged during prolonged idling, even with continuous loads like air conditioning and lights.

Lower thermal stress from reduced relative loads helps preserve internal components, including bearings, drive belts, and electrical connections. Over time, the reduced need for maintenance and potential fuel savings can make the investment in an oversized alternator worthwhile.

Factors to Consider When Sizing an Alternator

After diving into alternator efficiency, it’s clear that sizing your alternator correctly is essential for optimal performance. The right size depends on calculating your electrical load and understanding your vehicle's mechanical setup. Nail these factors, and your alternator will operate efficiently without the headaches caused by undersizing or excessive oversizing.

Two key considerations are total amperage demand and pulley ratios. Your electrical load determines the minimum capacity, while pulley ratios dictate how much power the alternator can deliver at various engine speeds. This balance is especially critical at idle, where many vehicles struggle to maintain adequate charging.

Calculating Your Electrical Load

Start by adding up the amperage draw of all your vehicle’s components. Make a list of each accessory’s power rating and total them up. For instance:

- Air conditioner: 20-21 amps

- Headlamps (high beam): 13-15 amps

- Electric cooling fans: 6-15 amps (up to 30 amps for high-performance models)

To get the most accurate numbers, use an ammeter. Connect it to the battery ground with the engine off, then turn each component on and off individually to measure its draw. Add these figures together.

Once you’ve calculated the total load, include a 50% safety margin to account for power spikes or future upgrades. For example, if your load is 80 amps, choose an alternator rated for at least 120 amps. Keep in mind that alternators are rated at 6,000 RPM shaft speed, but their output drops significantly at idle, typically around 1,500 RPM. Your alternator needs to supply enough power at idle to meet your continuous load.

If you’re upgrading to a higher-output alternator, don’t forget to upgrade your wiring too. For a load of 65-85 amps, use at least 6 AWG wire for lengths up to 7 feet, or 4 AWG for lengths up to 13 feet. Undersized wiring can cause voltage drops, negating the benefits of a bigger alternator.

Now, let’s explore how pulley ratios come into play.

How Pulley Ratios Affect Performance

Pulley ratios determine how fast your alternator spins compared to engine speed. To calculate the ratio, divide the crankshaft pulley diameter by the alternator pulley diameter. For example, a 6-inch crank pulley paired with a 2-inch alternator pulley gives you a 3:1 ratio. This ratio works well for most street vehicles, ensuring adequate charging at idle.

The ratio directly affects alternator output at different speeds. A higher ratio (smaller alternator pulley) boosts output at idle and low speeds but risks over-spinning the alternator at high RPMs. Most alternators have a maximum continuous speed limit of about 15,000 RPM. Exceeding this limit doesn’t improve performance - it increases heat, reduces efficiency, and can damage bearings. As Brian Wagner puts it:

If you spin the alternator harder than the optimal rpm level it won't increase output, it could actually damage the alternator.

Aim for an alternator speed of at least 3,000 RPM at engine idle and 5,000-8,000 RPM at cruising speeds. To ensure you stay within safe limits, multiply your engine’s maximum RPM by the pulley ratio. For example, a 3:1 ratio with a 6,000 RPM redline results in 18,000 alternator RPM - well above the safe threshold. In this case, you’d need a larger alternator pulley or a different alternator design.

Different use cases call for different ratios. For drag racing, a 1.75:1 or higher ratio is ideal to maintain charging during staging. Circle track racing, on the other hand, often uses a 1:1 ratio to avoid over-spinning during extended high-speed runs. Additionally, proper belt wrap and pulley alignment are crucial. Opt for billet steel pulleys rather than stamped sheet metal to prevent warping and belt glazing.

Modern Alternator Designs for Small Spaces

Modern alternator designs are tackling the challenge of limited space head-on, offering higher output in more compact forms. This evolution is particularly beneficial for compact equipment and high-performance vehicles where every inch of space matters. Instead of simply shrinking existing designs, manufacturers have rethought the entire process of power generation and management. The result? Alternators that are up to 20% lighter than traditional models while still matching - or even exceeding - their output capacity.

High-Output Compact Alternators

One of the standout innovations in compact alternator technology is the move from traditional round wire to rectangular segment conductors in the stator coil. This adjustment eliminates air gaps, increasing winding density from 45% to 70%. The result is a significant reduction in resistance and thermal loss - key factors for improving efficiency. Additionally, cold-forged rotor cores enhance the magnetic circuit, and miniaturized single-chip IC regulators are integrated directly into the housing, making the alternator even more compact.

Ruslan Leontiev, Product Manager at DENSO Europe, highlights the importance of these advancements:

Emerging smart charging technology offers reliability and precision in the control of alternator output generation and distribution... we not only enable vehicles to maximise their electrical output, but to do so without affecting its design, weight or environmental performance.

Thermal management has also seen significant improvements. Integrated fan blades enhance airflow, cooling internal components without requiring additional hardware. Smaller pulley diameters allow the alternator to spin faster relative to engine speed, ensuring maximum output even at idle - a critical advantage for space-constrained applications. These design changes ensure that compact alternators deliver dependable performance, even under demanding conditions, while maintaining the efficiency and durability essential for modern systems.

Finding the Right Alternator on Electrical Trader

Once you've determined your electrical load and efficiency needs, Electrical Trader makes it easy to find the perfect alternator. Their platform allows you to filter by key factors like amperage output, voltage, and mounting style, streamlining the selection process. Whether you're looking for a unit for a standard passenger car or an industrial generator, you'll find both new and remanufactured options to suit your requirements. You can even filter by both rated output (6,000 RPM) and idle output (1,500 RPM) to ensure the alternator meets your real-world performance needs. Keep in mind that idle output is much lower than peak capacity. For example, a Ford 110-amp alternator might only deliver about 47 amps at 600 RPM idle.

Voltage and mounting compatibility are just as important. Select the proper system voltage - 12V for most automotive uses or 24V for industrial equipment - and ensure the mounting style and SAE flange/shaft standards match your setup. For generator applications, consider the number of poles: 2-pole alternators (3,000 RPM) are ideal for intermittent use, while 4-pole alternators (1,500 RPM) are designed for continuous industrial operation.

When deciding between new and remanufactured units, new alternators offer the best reliability, whereas remanufactured ones are more budget-friendly. Just ensure that your drive belt and wiring can handle the required amperage. Once you've set your filters, you can compare ratings to find the right match for your application.

Alternator Ratings by Application

For standard needs, a 100-amp alternator is usually sufficient. However, high-demand setups - like those with audio amplifiers or power seats - may require alternators rated at 200 amps or more to avoid overheating or draining the battery. High-output aftermarket alternators are also an option, offering performance advantages. For instance, a 250-amp alternator can provide 125 amps at idle, compared to the 47 amps produced by a standard 110-amp unit at the same speed.

To ensure reliability, your alternator’s rated output should exceed your total electrical draw by at least 50%. For industrial applications, 24V alternators typically range from 2,400 to 7,200 watts, making them well-suited for continuous-duty operations where dependability is critical.

Conclusion

Selecting the correct alternator size plays a key role in improving system efficiency, ensuring reliability, and lowering long-term costs. A properly sized alternator reduces fuel consumption and avoids overheating, which can lead to component failure over time. When matched to your load profile, it also cuts down on mechanical wear caused by vibrations and abnormal stresses, extending the lifespan of both the engine and the alternator itself.

Another benefit of using the right alternator is maintaining battery health. An undersized unit can cause repeated partial discharges, which shorten battery life. As Everett Seymoure, Global Manager at TRP Aftermarket Parts, points out, truck operators should avoid skimping on alternator capacity, as doing so can negatively affect battery longevity and overall system performance.

It's worth noting that standard automotive or marine alternators can only sustain about 50% to 67% of their maximum output continuously without overheating. To maintain reliability, your alternator's rated output should exceed your total electrical demand by at least 50%. Additionally, ensure your drive belt can handle the increased amperage. For instance, a 3/8" V-belt supports up to 80 amps, while a 1/2" V-belt can manage 120 amps.

With these factors in mind, choosing the right alternator becomes much simpler. Platforms like Electrical Trader offer tools to filter options by amperage output, voltage, mounting style, and application type. Whether you need a compact, high-output alternator for automotive use or a 4-pole alternator for industrial applications, they provide both new units (priced between $100 and $600) and cost-effective remanufactured options. Matching your specific needs with the right alternator can help cut operational costs, reduce downtime, and extend the lifespan of your entire electrical system.

FAQs

How do I size an alternator for my real-world load at idle?

To determine the right alternator size for idle, start by calculating the total amperage your electrical accessories consume. Make sure the alternator can provide sufficient current even at idle RPM. Pay attention to the pulley ratio, as it directly impacts the alternator's shaft speed. It's smart to select an alternator with an amperage rating that exceeds your total load at idle. This ensures dependable performance, especially for power-hungry accessories like cooling fans.

Will a higher-amp alternator increase fuel use on my vehicle?

A higher-amp alternator doesn’t automatically mean your vehicle will use more fuel. It generates only the amount of current your electrical systems need. If your vehicle’s electrical demand doesn’t increase, the alternator won’t draw additional power, so your fuel consumption will stay the same.

What pulley ratio prevents over-spinning my alternator?

To keep your alternator running smoothly and avoid damage, aim for a pulley ratio of 2:1 or lower. This helps prevent over-spinning, keeping the alternator within its recommended RPM range. Be sure to review your alternator's specifications to determine the right pulley ratio for your system.