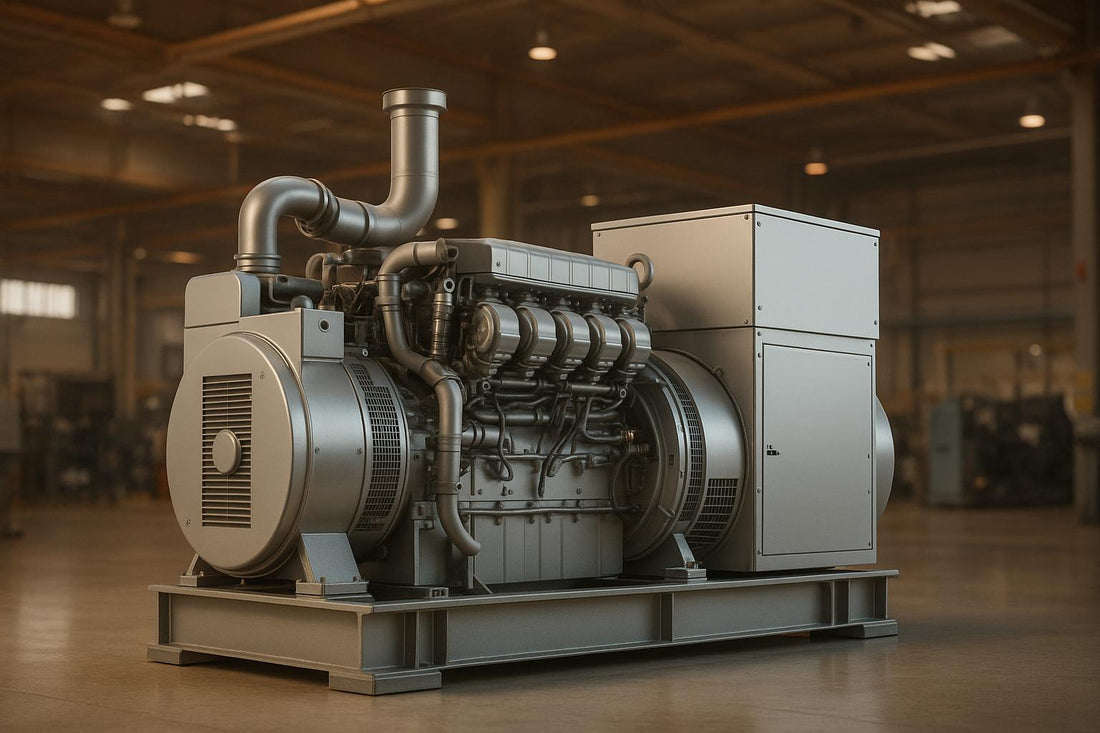

Industrial Generator Sizing: Key Factors

Share

Choosing the right industrial generator size is critical to avoid costly mistakes. Too small, and you risk equipment failures and power outages. Too large, and you waste fuel and increase maintenance costs. Here's a quick breakdown of what you need to know:

- Why It Matters: Proper sizing ensures energy efficiency, reliability, and long-term savings.

-

Main Challenges:

- Load uncertainty: Motors often need much more power to start than to run.

- Modern equipment: Complex loads like VFDs and LED lighting create calculation challenges.

- Future growth: Failing to plan for expansion can lead to inefficiencies.

-

Key Factors:

- Use accurate load calculations (real-time measurement, historical data).

- Account for environmental conditions like altitude and temperature.

- Include a 20–30% safety margin for future needs.

Pro Tip: Tools like power analyzers and generator sizing software can simplify the process. For complex setups, consult experts to avoid errors. Proper planning ensures reliable backup power and reduces long-term costs.

Diesel Generator Design Calculations: A Complete Guide for Engineers | Sizing, Load, and More!

Main Challenges in Industrial Generator Sizing

Sizing industrial generators is no small feat. Missteps in this process can lead to expensive operational hiccups and inefficient planning. By understanding the key challenges, businesses can make smarter decisions about their backup power needs.

Load Uncertainty and Changing Needs

Daily power usage isn’t always predictable, and relying on inaccurate assumptions can result in undersized generators. Traditional sizing methods often fail to account for the full range of power fluctuations, leaving systems ill-equipped to meet real-world demands.

Take motor loads, for example. Unlike lighting, motor loads can cause frequency dips and require high starting kVA, especially those with high inertia. These loads demand the generator provide starting current for extended periods, which can push an undersized system to its limits. On top of that, factors like elevation and ambient temperature can reduce a generator’s output capacity, a phenomenon known as derating.

"A generator is like a magnet; once someone knows a building has one, their equipment must be powered by it." - Dan Zang, Lead Electrical Engineer at Hallam-ICS

This “magnet effect” often leads to scope creep, where backup power designed for essential systems ends up accommodating non-critical loads, further increasing demand. And as if that weren’t enough, modern electrical systems bring their own set of challenges.

Modern Electrical Load Complexities

Today’s electrical loads are more intricate than ever, with components like Variable Frequency Drives (VFDs) and Uninterruptible Power Supplies (UPS) introducing complications. These systems can create harmonic distortions, making load calculations tricky. Generators, with their higher internal impedance, are especially vulnerable to total harmonic voltage distortion (THvD), which can cause equipment problems that wouldn’t occur on utility power.

Voltage distortion becomes even more pronounced in 208V configurations, where subtransient reactance is about 33% higher. Elevator systems add another layer of complexity. Cable/traction elevators, for instance, often use four-quadrant VFD technology, requiring the alternator to handle both harmonic content and regenerative power. This regenerative energy can flow back into the generator, creating unexpected load conditions.

Interestingly, about 85% of voltage disturbances originate within a facility itself. While minor fluctuations from the utility grid might go unnoticed, they can become major issues when running on generator power, which has different electrical characteristics. This makes it critical to account for these complexities during the planning phase.

Future Load Growth and Scalability

Planning for future expansion without oversizing a generator is a balancing act. Undersizing can leave facilities scrambling to prioritize essential over optional loads during emergencies. On the flip side, oversizing can lead to underutilized generators, which may cause issues like wet stacking in diesel systems if they don’t operate at a minimum 30% load.

Effective capacity planning is about more than just meeting current needs - it’s about anticipating future changes. This includes shifts in manufacturing processes, technology upgrades, and facility expansions. One smart approach is to use paralleling generators, which allow phased capacity increases over time. This strategy not only supports growth but also avoids the need for costly electrical upgrades down the line.

Scalability should also extend to associated systems, such as modular UPS units and distribution infrastructure. A flexible initial design can save significant costs and headaches when future expansion becomes necessary. Proper planning ensures that facilities can adapt seamlessly to growth while maintaining reliable power for all critical operations.

Key Factors for Correct Generator Sizing

When it comes to generator sizing, accuracy is everything. A properly sized generator can handle critical loads when it matters most, while a poorly chosen one might fail at the worst possible time. To get it right, you need to consider several technical and environmental factors. Here's a closer look at what goes into proper generator sizing.

Load Calculation Methods

Understanding your power needs starts with accurate load calculations. Several methods can help you determine the right generator size:

- Real-time measurement: This approach gives you a clear picture of your current energy use. Use a clamp-on ammeter to measure amps on each electrical leg. For three-phase systems, divide the total amps by three; for single-phase systems, divide by two. Multiply the result by your supply voltage and then by 1,000 to convert it into kilowatts.

- Historical data analysis: Reviewing past utility bills provides insight into peak demand patterns. Add a 25% reserve capacity to account for seasonal changes and operational fluctuations.

- Motor load calculation: Motors, especially those in compressors or similar equipment, often require much more power to start than to run. Starting loads can be up to six times the running load. Calculate the starting current for your largest motor, multiply it by the supply voltage, and add this to the other motor and non-motor loads. Include a 25% buffer for reserve capacity.

- Square footage estimation: While less precise, this method offers a basic starting point for planning, particularly for smaller facilities or initial assessments.

Once you've calculated your load requirements, it's essential to account for how power factor and load types influence generator performance.

Power Factor and Load Type Effects

The power factor is a crucial element in generator sizing, as it measures how efficiently electrical power is converted into usable energy. It’s essentially the ratio of real power (kW) to apparent power (kVA). Most generators are rated with an industry-standard power factor of 0.8, meaning they operate at about 80% efficiency.

Different types of electrical loads impact the power factor:

- Resistive loads, like heating elements, typically have a power factor of 1.0.

- Inductive loads, such as motors, often create a lagging power factor.

- Capacitive loads result in a leading power factor.

For most industrial facilities, a lagging power factor of 0.8 is common due to the prevalence of motors. In newer buildings, a power factor of 0.9 may be used for estimates when the actual figure isn’t available. Single-phase generators usually run at a power factor of 1.0, while three-phase generators operate closer to 0.8.

A low power factor (below 0.8) can reduce a generator's effective capacity by increasing current flow. In such cases, power factor correction - like adding capacitors - can improve efficiency and prevent overloading.

Beyond these calculations, environmental factors also play a significant role in determining generator performance.

Site Conditions and Environment

Environmental conditions can have a major impact on how well a generator performs. Standard ratings assume ideal conditions, but real-world installations often face challenges that require adjustments.

- Altitude: Generators lose power output at higher elevations. Gasoline, diesel, and propane generators see a 2–3% drop per 1,000 feet, while natural gas models lose about 5% per 1,000 feet.

- Temperature extremes: Cold weather can cause diesel fuel to gel, while high temperatures force generators to work harder to stay cool.

- Other environmental factors: High humidity, strong winds, and flooding can all affect generator efficiency and durability. For example, strong winds might carry debris into the generator’s intake or exhaust systems, while flooding can damage electrical components.

Fuel type also matters. In colder climates, diesel generators may require additives or heated fuel systems to prevent gelling. Natural gas availability can vary by region, and propane storage requires careful planning and adequate space.

Finally, it’s wise to add a safety margin of 20–30% to your total power requirements when considering standby generators, especially in challenging environments. Maintenance is another critical factor - generators in harsh conditions often need more frequent servicing, and limited access for maintenance can lead to performance issues over time.

sbb-itb-501186b

Solutions and Best Practices for Generator Sizing

Getting the sizing of a generator right is all about using the right tools, setting clear priorities, and seeking expert advice. These strategies can help industrial facilities sidestep costly errors and ensure dependable backup power when it’s most needed.

Using Load Analysis Tools

Accurate generator sizing starts with precise load measurement and analysis. Modern tools make it easier to avoid the common pitfalls of overestimating or underestimating power needs.

Power analyzers are the go-to devices for assessing electrical loads. Unlike simpler tools like oscilloscopes, power analyzers are specifically designed for detailed and accurate measurements. By using power analyzers, load banks, and data recorders, you can simulate real-world operating conditions and capture peak demand patterns with precision. The key is to rely on well-calibrated equipment that can handle the complexity of industrial systems.

Generator sizing software has also become a valuable tool, with options available from leading manufacturers like Cummins, Caterpillar, Generac, and Kohler. As Danna Jensen notes:

"The most important factor in using generator sizing software is to know as much as possible about the loads and remember that sometimes it can be more of an art than a science. The more exact the data input - as opposed to using the system default parameters - the more accurate the required generator size will be."

When performing load analysis, it’s crucial to gather detailed data on every device and system the generator will support. This includes wattage ratings, surge power needs, and operating schedules. Avoid relying solely on nameplate data, as actual operating conditions often differ significantly from the manufacturer’s specifications.

Regular load assessments are especially important in facilities where equipment is updated or replaced frequently. For critical applications, consulting with certified professionals can help interpret complex load patterns and establish appropriate safety margins. This groundwork is essential for making informed decisions about load prioritization.

Prioritizing Critical and Non-Critical Loads

Effective load prioritization can significantly reduce the size of the generator required while ensuring that vital operations remain uninterrupted during power outages. This process, often referred to as load shedding, involves ranking electrical loads based on their importance to the facility’s operations.

- Critical loads are systems that demand uninterrupted power with high reliability. These typically include safety systems, process control equipment, and essential production machinery in industrial settings.

- Non-critical loads can be temporarily disconnected without disrupting core operations.

- Essential loads fall somewhere in between. These systems, like emergency lighting or communication networks, are necessary for safety but don’t require continuous power.

When prioritizing loads, consider factors such as financial losses from downtime, production costs, health and safety risks, security concerns, and potential damage to your organization’s reputation. Develop a detailed priority list that accounts for both the importance of each load and the duration it needs to run during an outage.

Load management systems can automate this process. These systems balance the generator’s electricity supply with demand by automatically adding or shedding loads based on pre-set priorities. Pairing a controller with an automatic transfer switch (ATS) and external relays ensures that critical operations remain functional without overloading the generator.

For operations that cannot afford any interruptions, consider implementing N+1 redundancy. This approach involves having an additional backup unit ready to take over if the primary system fails, providing extra peace of mind for the most critical systems.

Getting Expert Resources from Electrical Trader

Navigating the complexities of generator sizing becomes much easier with the right guidance and access to specialized equipment. Electrical Trader offers a comprehensive solution for professionals handling generator installations, providing both the products and expertise needed for success.

Electrical Trader’s platform includes a wide range of emergency standby generators and power generation components, ensuring you can find equipment that matches your specific load requirements and budget.

Beyond just equipment, Electrical Trader connects you with experts who understand the nuances of industrial power systems. Their network of specialists can assist with selecting the right products and performing complex sizing calculations.

For facilities needing transformers, switchgear, or distribution equipment to complement their generator installations, Electrical Trader offers everything from 3-phase transformers to substation components. This one-stop-shop approach simplifies procurement and ensures that all system components are compatible.

The platform’s resource center provides buying guides and technical information to help you make informed decisions. These resources, combined with professional consultation, offer valuable insights into generator sizing and related equipment.

For projects involving older facilities or discontinued models, Electrical Trader’s inventory includes both new and reconditioned equipment. This flexibility is especially useful when retrofitting existing systems or replacing obsolete components.

By comparing options from multiple suppliers on the marketplace, you can find the best value for your needs. Whether you’re looking for a complete generator package or individual components like circuit breakers, disconnects, or control systems, Electrical Trader offers access to everything required for professional installations.

For unique or challenging projects, working with experienced suppliers through Electrical Trader can provide the specialized knowledge needed to avoid costly mistakes and ensure reliable performance.

Conclusion and Key Points

Sizing industrial generators isn’t as simple as matching power ratings to equipment nameplates. It’s a complex process that requires careful consideration and planning. Mistakes in this area can lead to costly consequences, but with the right strategies and tools, professionals can ensure reliable backup power when it’s needed most.

Main Challenges in Generator Sizing

Generator sizing comes with three major challenges that even seasoned professionals often face:

- Load uncertainty: Facilities are constantly evolving - new equipment is added, processes are modified, and operational patterns shift. Relying solely on nameplate data often leads to miscalculations, as it doesn’t reflect real-world power demands.

- Modern electrical complexities: Today’s industrial setups deal with harmonics, non-linear loads, and advanced control systems, which behave differently than traditional resistive loads. Power factor considerations, especially with generators typically rated for a 0.8 power factor, add to the complexity.

- Future scalability: Generators must meet current power needs while also being able to handle future growth. Misjudging this balance can leave facilities with undersized units that fail to meet demand or oversized ones that waste resources. Environmental factors such as high altitudes, extreme temperatures, and humidity further complicate sizing, often requiring adjustments to initial calculations.

These challenges highlight the importance of a well-thought-out approach to generator sizing.

Practical Tips for Professionals

To overcome these challenges, here are some actionable strategies for accurate generator sizing:

- Leverage power analyzers for detailed load analysis: Instead of relying on rough estimates or nameplate data, use power analyzers and review past energy bills to get a precise understanding of your facility's actual power needs.

- Incorporate a safety margin: Adding a 20–30% buffer can account for load growth, unexpected variations, and measurement uncertainties, ensuring your generator can handle future changes.

- Prioritize loads: Identify the systems that must remain operational during outages and those that can be temporarily disconnected. This load-shedding approach helps reduce the generator size needed while keeping critical operations running.

- Choose the right fuel type: Consider your operational needs when selecting a fuel type. Each option has its own pros and cons regarding cost, availability, and storage.

- Consult experts: Work with certified professionals, generator manufacturers, or specialists to validate your calculations and ensure your approach is sound.

- Consider paralleling generators: Using multiple generators in parallel offers flexibility for future expansion and provides redundancy, ensuring reliable power even if one unit fails.

Proper generator sizing doesn’t just ensure uninterrupted power - it can also improve fuel efficiency by up to 30%, making the investment in accurate calculations worthwhile. The cost of mis-sizing a generator far outweighs the effort and resources required to get it right.

For complex or unique projects, platforms like Electrical Trader can connect you with specialized equipment and expert insights to tackle even the toughest sizing decisions.

FAQs

How do I determine the right generator size for my facility's power needs?

To determine the right generator size, begin by listing all the electrical equipment your facility relies on, such as motors, appliances, and other devices. Take note of their running wattage and starting wattage. Combine these numbers to find your total power needs.

To ensure reliability, factor in a safety margin by multiplying the total wattage by 1.2 to 1.3. This extra capacity allows the generator to manage peak demands and unexpected power surges. Conducting a detailed load assessment is key to avoiding overloads and maintaining a steady power supply for your operations.

What challenges arise with traditional generator sizing methods, and how can modern tools improve accuracy?

Traditional methods for sizing generators often run into problems like uncertain load requirements, misjudged power needs, and challenges in considering factors like power factor or motor startup demands. These missteps can result in generators that are too small, causing performance issues, or too large, leading to wasted money.

Today, modern tools like advanced sizing software are changing the game. They offer precise load calculations, take complex variables into account, and reduce the risk of human error. The result? A more accurate sizing process that ensures dependable generator performance while keeping costs in check for industrial applications.

How does the type of fuel affect the efficiency and performance of an industrial generator?

The type of fuel you choose significantly impacts how well an industrial generator performs, how much it costs to run, and how efficient it is. Diesel stands out as a popular option because of its high energy density, longer runtime, and reduced fuel consumption. These qualities make diesel generators a reliable choice for heavy-duty industrial tasks, especially when consistent power over long periods is essential. They tend to perform best when operating within their optimal load range, ensuring dependable energy output.

Natural gas is another strong contender, particularly valued for its cleaner emissions and consistent availability when connected to a pipeline. With access to natural gas infrastructure, this option can deliver efficient and steady performance, making it suitable for many applications. Ultimately, the right fuel choice hinges on factors like fuel availability, environmental considerations, and the specific energy demands of the job.

Related posts

- Top 5 Power Generation Tools for 2025

- How to Choose the Right Electrical Breaker Size

- Ultimate Guide to Standby and Prime Generators

- How to Improve Generator Fuel Efficiency