Factors Impacting Diesel Generator Fuel Use

Share

Diesel generator fuel consumption depends on several factors, including load levels, maintenance, environmental conditions, generator design, and fuel quality. Operating a generator efficiently - typically at 70–80% of its rated capacity - can reduce fuel waste, lower costs, and extend its lifespan. Poor maintenance, incorrect load levels, and extreme conditions can drive up fuel usage and lead to costly repairs.

Key takeaways:

- Optimal Load Range: Generators perform best at 70–80% capacity.

- Low Load Risks: Operating below 60% capacity can cause wet stacking, wasting fuel and damaging the engine.

- Maintenance: Regular servicing (e.g., cleaning filters, replacing oil) improves combustion and reduces fuel waste.

- Environmental Factors: High altitudes and extreme temperatures increase fuel consumption.

- Generator Sizing: Using the right-sized generator prevents inefficiencies and unnecessary wear.

Efficiency of Diesel Generator

How Load Management Affects Fuel Efficiency

Getting the most out of your diesel generator isn’t just about keeping it running - it’s about running it smartly. By managing load levels effectively, you can reduce fuel consumption and cut operational costs. But here’s the thing: the relationship between load levels and fuel usage isn’t as simple as you might think. For instance, running a generator at 50% capacity doesn’t mean it uses half the fuel. In reality, it typically burns around 55–65% of the fuel it would at full load. Diesel engines tend to perform best when operating at higher loads.

The "sweet spot" for efficiency is typically between 70% and 80% of a generator’s rated capacity. At this range, the engine uses fuel most efficiently, producing maximum power with minimal waste. For example, a 200 kW generator running at 75% load might consume about 5–6 gallons of fuel per hour. Compare that to running it at 25% load, which uses 2–3 gallons per hour - clearly, efficiency isn’t linear. Straying too far from this optimal range can lead to wasted fuel and increased wear on the equipment.

"If you think your unit running at 50% load will use half the fuel, think again. That's not how diesel engines operate. They're more efficient at higher load levels, up to a point." - General Power

Problems Caused by Incorrect Load Levels

Operating your generator outside its ideal load range can lead to a host of problems. Running at low loads - typically below 30–50% - can cause a condition called wet stacking. This happens when the operating temperature is too low for complete fuel combustion, leaving unburned diesel behind. Over time, this buildup can clog exhaust valves, turbochargers, and injectors.

"Diesel generator efficiency is usually achieved at the higher end of the load setting the generator was designed to maintain." - CK Power

Low-load operation also increases emissions and can lead to more frequent maintenance needs. Running below 60% capacity for long periods is often described as "burning cash" because the amount of fuel used per kilowatt of output becomes disproportionately high.

On the flip side, while running your generator at 100% load maximizes output, doing so continuously can accelerate wear and tear, reducing the equipment’s lifespan. Operating in the 70–80% range strikes the best balance between output and longevity.

| Load Level | Fuel Consumption (% of Full Load) | Efficiency Status |

|---|---|---|

| 25–30% | 35–40% | Inefficient; wet stacking risk |

| 50% | 55–65% | Sub-optimal |

| 70–80% | 80–85% | Peak efficiency |

| 100% | 100% | High output; increased wear |

How to Manage Load Effectively

Knowing how load levels impact efficiency can help you make smarter decisions. One of the best strategies is to use a generator that’s properly sized for your typical power needs, ensuring it operates in the 70–80% load range most of the time. For sites with fluctuating energy demands, modular setups with multiple smaller generators running in parallel can be more efficient than relying on one oversized unit. This approach allows you to adjust capacity as needed, keeping loads in the optimal range.

For example, a hospital with two generators managed to save about $40,000 annually by optimizing its load levels. Similarly, a logistics center reduced idle time by 17% by using fuel sensors to monitor efficiency.

Accurate monitoring tools are key to maintaining efficiency. Load meters and sensors can alert you when loads drop below 60%, giving you the chance to make adjustments before fuel is wasted. In cases where generators must run at light loads - like during standby operations - using a load bank periodically can help burn off carbon deposits and prevent wet stacking.

Standby and prime diesel generators are typically designed to run best between 50–80% of their rated capacity, while continuous-rated units perform more efficiently in the 70–100% range. Automated systems, such as transfer switches and load management tools, can also help distribute power to critical circuits and maintain steady loads without constant manual input.

Maintenance Practices for Better Fuel Combustion

Neglecting maintenance can lead to higher fuel consumption and increased operating costs. Issues like clogged air filters, degraded fuel injectors, and old oil force the generator to work harder, burning more diesel to achieve the same output. This not only raises costs but also increases the risk of breakdowns.

Common Maintenance Problems That Increase Fuel Use

Clogged air filters block airflow, resulting in incomplete combustion and higher diesel usage. Without enough oxygen, the engine operates with an inefficient fuel-to-air ratio, wasting fuel.

Dirty fuel injectors are another major culprit. They disrupt proper atomization, reducing fuel efficiency by 2%–10%. Problems like carbon buildup, worn internal components, or faulty O-rings prevent the fine fuel mist necessary for efficient combustion.

"If injectors are not spraying fuel as a fine atomization - like fuel droplets - the fuel will not completely burn, and it will either be pushed out the exhaust or some of it will end up in the oil" - Clay Parks, VP of Development, Rislone

Old or degraded oil leads to sludge and impurities, increasing internal friction. This forces the engine to work harder and burn more fuel. Similarly, cooling system issues, such as blocked radiators or low coolant levels, can cause overheating, accelerating engine wear and reducing efficiency. Fuel contamination from water or microbial growth clogs fuel lines and filters, stressing the fuel pump and degrading combustion quality.

One of the most severe issues is cylinder glazing, which happens when low-load operation causes a shiny coating to form on cylinder walls. This prevents piston rings from sealing properly, leading to low compression and significant fuel waste.

"When an engine runs under low loads, it results in lower cylinder pressures and poor piston ring sealing... leading to poor combustion, resulting in soot formation and unburned fuel residues" - Aurora Generators

For example, in June 2025, WALT POWER reported a case involving a 100 kW diesel generator with clogged injectors. Poor maintenance caused fuel consumption to spike by 15%, while power output dropped, resulting in an efficiency of just 9 kWh per gallon. After replacing the injectors and servicing the filters, efficiency improved to 11.5 kWh per gallon.

Regular Servicing to Reduce Fuel Waste

Routine maintenance is key to preventing these issues and minimizing fuel waste. A consistent servicing schedule can save fuel and avoid costly repairs.

- Air filters should be inspected monthly and replaced if dust buildup is visible. In dusty environments, more frequent checks are necessary.

- Oil and oil filters need changing every 200–500 hours of operation, depending on the generator model and usage conditions. Fresh oil reduces friction and ensures smooth engine performance. Similarly, fuel filters should be replaced every 250–500 hours to keep contaminants out of the injectors.

- Fuel injectors should be professionally cleaned or serviced every 20,000–30,000 miles (or equivalent operating hours) to maintain proper atomization. Preventive care here is far cheaper than emergency repairs.

Load bank testing is another essential practice. Running the generator at full capacity periodically helps burn off carbon deposits and can even reverse cylinder glazing. This is especially important for generators that frequently operate below 30% capacity. Annual load bank tests at 75% capacity or higher can restore efficiency and prevent wet stacking.

The cooling system also requires regular attention. Flush the system and replace coolant per manufacturer guidelines to prevent mineral buildup and corrosion. Check coolant levels often, particularly during hot weather when generators are under more strain.

Lastly, monitor fuel quality. Diesel should not be stored for more than 6–12 months without treatment. Use fuel polishing services to remove sediment and water, and add stabilizers if the generator will sit idle for long periods. Over half of bulk diesel storage tanks experience water contamination due to condensation or poor storage, making regular maintenance essential.

| Maintenance Task | Recommended Frequency | Impact on Fuel Efficiency |

|---|---|---|

| Air Filter Inspection | Monthly | Ensures complete combustion |

| Oil & Oil Filter Change | Every 200–500 hours | Reduces internal friction |

| Fuel Filter Replacement | Every 250–500 hours | Maintains optimal fuel flow |

| Injector Cleaning/Service | Every 20,000–30,000 miles | Restores 2%–10% fuel economy |

| Load Bank Testing | Annually or as needed | Burns off carbon deposits |

| Cooling System Flush | Annually | Prevents overheating |

Environmental and Operating Conditions

Environmental factors like temperature, altitude, and airflow can have a big impact on fuel efficiency. These conditions affect combustion, engine cooling, and the availability of oxygen, all of which influence how efficiently a generator runs.

How Environmental Factors Affect Generator Efficiency

Extreme temperatures are a major challenge. Diesel engines operate most efficiently around 77°F (25°C). When temperatures rise above 95°F (35°C), fuel consumption goes up by about 2% for every 9°F (5°C) increase. At the same time, power output drops roughly 1% for every 10°F (6°C) increase above 60°F (16°C). This happens because hot air is less dense, which reduces the oxygen available for combustion and leads to inefficiencies.

Cold weather isn’t any easier. When temperatures dip below 50°F (10°C), fuel consumption increases by 3% for every 9°F (5°C) decrease. Cold starts are particularly problematic because the engine struggles to reach its optimal temperature. This can lead to incomplete combustion and a condition called wet stacking, where unburned fuel and carbon build up in the exhaust system. As a result, the engine burns extra diesel during startup, and performance suffers until the engine warms up.

High altitudes bring their own set of challenges. With thinner air at higher elevations, oxygen levels drop, making it harder for the engine to burn fuel completely. For every 1,000 feet above sea level, power output decreases by about 3.5%, while fuel consumption rises by 6% to 8% for every 3,280 feet (1,000 meters). This can lead to problems like black smoke and higher emissions.

Ventilation also plays a big role. Poor airflow makes it harder for the engine to get the air it needs, which increases fuel consumption. Ensuring proper ventilation and keeping filters clean can help reduce these inefficiencies.

| Environmental Factor | Condition Change | Impact on Fuel Consumption |

|---|---|---|

| High Temperature | Every 9°F (5°C) above 95°F (35°C) | 2% increase |

| Low Temperature | Every 9°F (5°C) below 50°F (10°C) | 3% increase |

| Altitude | Every 3,280 feet (1,000 m) | 6–8% increase |

| Power Output Loss | Every 1,000 feet elevation | 3.5% decrease |

Adjusting Operations for Different Conditions

To counter these environmental challenges, specific adjustments can help improve generator efficiency.

In colder climates, using engine preheaters can help the engine reach its optimal operating temperature faster. This reduces the risk of wet stacking and other issues tied to cold starts.

For high-altitude operations, turbochargers are a practical solution. By forcing more air into the combustion chamber, they help maintain the proper air-to-fuel ratio, ensuring smoother operation. If a turbocharger isn’t an option, derating the generator - running it at 70% to 80% of its rated capacity - can prevent overheating and excessive wear. Keeping an eye on exhaust gas temperatures is also essential, as they tend to rise at higher elevations.

In hot conditions, improving ventilation can make a big difference. Installing larger vents, adding exhaust fans, or relocating the generator to a cooler space can help maintain a stable operating environment. Regular maintenance, like replacing air filters more often in dusty or high-altitude areas, also helps reduce fuel use.

For generators running in extreme conditions - whether due to heat, cold, or altitude - it's a good idea to run the unit at a minimum of 30% load for 30 minutes after every four hours of light-load operation. This helps burn off carbon deposits and keeps the combustion chamber clean, maintaining efficiency over time.

Next, we’ll look at how generator design and fuel quality play a role in fuel efficiency.

sbb-itb-501186b

Generator Design and Fuel Quality

The performance of your diesel generator and the quality of the fuel it uses play a huge role in determining fuel consumption. Older generators, built without today’s advanced controls and combustion technologies, often waste more fuel than necessary.

Inefficiencies in Older Generator Models

Generators from the early 2000s or earlier typically rely on mechanical fuel pumps, which lack precise fuel control. These older systems operate with a timing accuracy of plus-or-minus one degree, whereas modern electronic systems achieve precision within plus-or-minus 0.1 degree. Thanks to common-rail injection technology, newer models can reduce fuel consumption by 15% to 20% under similar load conditions. For instance, a 2023 generator with electronic injection consumed 18% less fuel compared to a 2015 model with a mechanical pump when both operated at 150kW.

Additionally, older generators lack digital governors and real-time engine management systems. Without these features, the air-fuel ratio often drifts from optimal levels, especially during load changes. Modern engines with electronic controls achieve mechanical efficiencies close to 45%, while older units typically fall between 30% and 35%. Maintenance intervals have also improved dramatically - modern systems can run up to 4,000 hours between services, more than double the lifespan of older designs. These advancements allow for more accurate fuel delivery, which directly improves efficiency.

Why Fuel Quality Matters

Even the most advanced generator won’t perform well if the fuel quality is poor. Contaminated diesel - whether from water, sediment, or microbial growth - can result in incomplete combustion and carbon buildup on injectors and engine components. Studies show that over 50% of bulk diesel storage tanks experience water contamination, often caused by condensation or faulty tank fittings. Poor fuel atomization forces the engine to work harder, consuming more diesel to deliver the same power output.

"Using high-quality diesel fuel that meets manufacturer specifications is essential. Contaminated or degraded fuel can lead to engine problems, reduced combustion efficiency, and increased wear and tear." - HS Generatorset

Modern generators demand clean, high-quality fuel. Even minor injector degradation can significantly lower efficiency. For example, cleaning fuel injectors every 1,000 hours can boost atomization efficiency by 1.8%. For generators that rely on long-term fuel storage, fuel polishing - a process that filters contaminants down to 3 microns - restores diesel to optimal condition and prevents performance issues.

Upgrading Equipment and Fuel Sources

If your generator is from the early 2000s, upgrading to a modern unit could save you a substantial amount in fuel costs over time.

"If you're still using a model built in the early 2000s, consider upgrading. The savings in fuel consumption alone could justify the investment over time." - General Power

Modern fuel injection systems are highly sensitive and require clean, uncontaminated fuel to operate efficiently. To ensure your generator runs smoothly, platforms like Electrical Trader connect buyers with reliable suppliers for both generators and essential components. Routine fuel testing and maintenance - such as calibrating control systems every 2,000 hours - can help maintain an ideal air-fuel ratio and prevent efficiency losses. These advancements in design and maintenance practices make it easier to match your generator to your specific power needs effectively.

Matching Generator Size to Power Needs

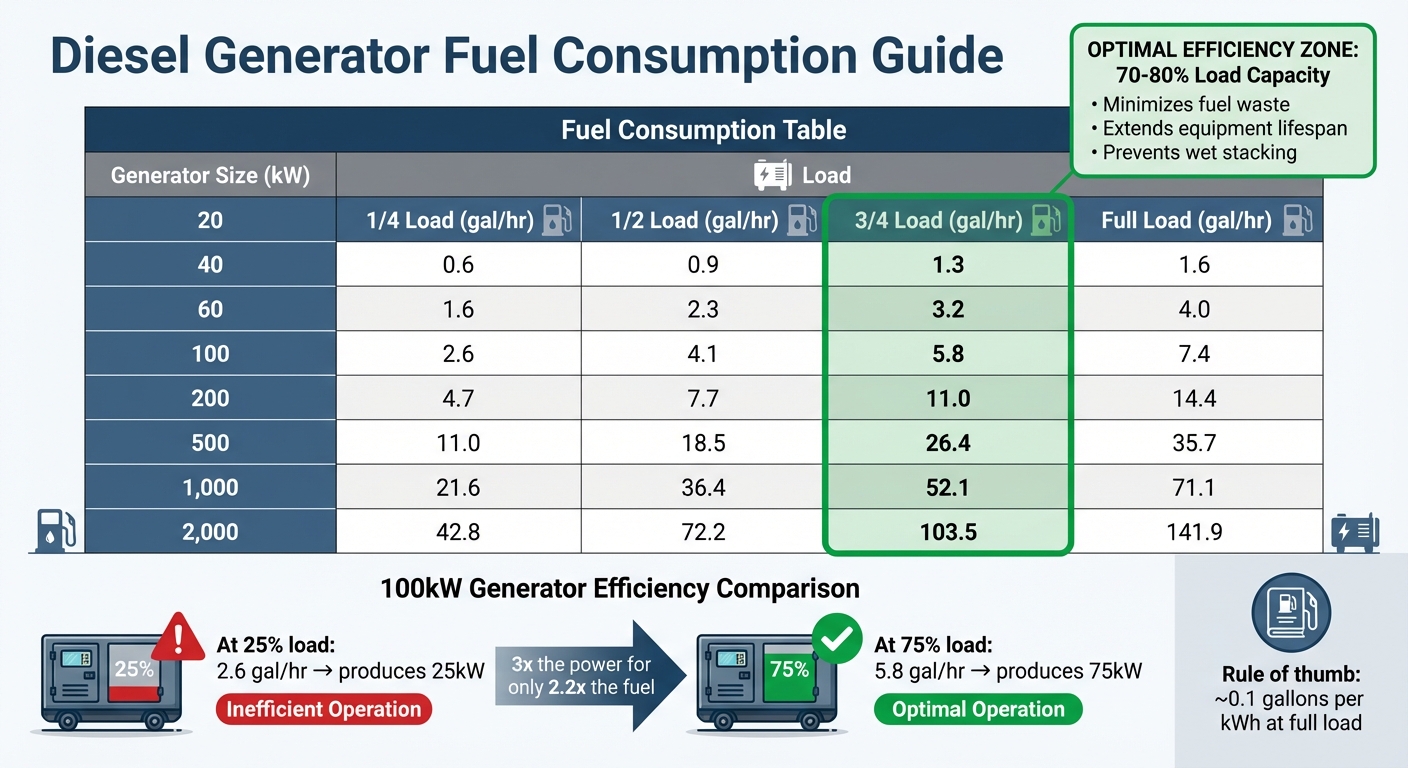

Diesel Generator Fuel Consumption by Load Level and Size

Getting the right generator size isn’t just about convenience - it’s a key factor in keeping fuel usage efficient. Choosing a generator that’s too large or too small can lead to wasted diesel, higher maintenance costs, and reduced equipment lifespan. Pairing the correct generator size with effective load management and regular maintenance can make a big difference in fuel efficiency.

Fuel Waste from Incorrect Generator Sizing

Using a generator that’s too large often leads to it running below 30% load. This low load operation can cause a condition called wet stacking, which not only wastes fuel but also wears out the engine faster. For example, WALT POWER shared a case from June 2025 where a client ran a 1,000kVA generator at just 20% load, thinking it would save fuel. The result? Increased maintenance expenses from engine issues wiped out any fuel savings. The client eventually switched to two smaller synchronized generators, cutting their yearly fuel consumption by 15%.

On the other hand, an undersized generator struggles to keep up with demand. This strain leads to problems like voltage drops, overheating, and higher fuel usage per kilowatt-hour produced. Not only does this reduce efficiency, but it can also shorten the generator’s lifespan and increase the risk of breakdowns.

"Fuel efficiency improves when the generator operates at 70-80% of its rating. Oversizing causes wet stacking and wastes fuel; undersizing forces the engine to work harder and reduce efficiency." - Depco Power Systems

Clearly, selecting the right generator size is essential for both performance and cost savings.

How to Select the Right Generator Size

Start by calculating both your average and peak power needs. Ideally, your generator should operate between 60% and 80% of its rated capacity during normal use. This range ensures optimal thermal efficiency while avoiding the pitfalls of running too light or too heavy.

Here’s a helpful rule of thumb: a diesel generator typically consumes about 0.1 gallons of fuel per kilowatt-hour (kWh) at full load. However, fuel consumption doesn’t scale perfectly. For instance, a generator running at 50% load still burns 55% to 65% of the fuel it would at full load. Manufacturer charts can provide more specific guidance for your generator model.

If your power needs fluctuate, consider using modular systems - multiple smaller generators working in parallel. This setup keeps each unit running in its efficiency sweet spot, rather than forcing a single large generator to operate inefficiently at low loads.

These strategies not only improve efficiency but also help manage fuel costs effectively.

Fuel Consumption by Generator Size

The table below highlights diesel fuel consumption for various generator sizes at different load levels. Notice how lower loads lead to disproportionate fuel usage. For example, a 100kW generator at 25% load consumes 2.6 gallons per hour, but at 75% load, it delivers three times the power while only using 5.8 gallons per hour.

| Generator Size (kW) | 1/4 Load (gal/hr) | 1/2 Load (gal/hr) | 3/4 Load (gal/hr) | Full Load (gal/hr) |

|---|---|---|---|---|

| 20 | 0.6 | 0.9 | 1.3 | 1.6 |

| 40 | 1.6 | 2.3 | 3.2 | 4.0 |

| 60 | 1.8 | 2.9 | 3.8 | 4.8 |

| 100 | 2.6 | 4.1 | 5.8 | 7.4 |

| 200 | 4.7 | 7.7 | 11.0 | 14.4 |

| 500 | 11.0 | 18.5 | 26.4 | 35.7 |

| 1,000 | 21.6 | 36.4 | 52.1 | 71.1 |

| 2,000 | 42.8 | 72.2 | 103.5 | 141.9 |

Real-world tests back up these figures. A data center ran a 72-hour load test on a 400kW generator, finding it consumed 6.2 gallons per hour at 40% load, 8.2 gallons per hour at 60% load, 10.2 gallons per hour at 80% load, and 12.2 gallons per hour at full load. These results confirm maximum efficiency occurs around 80% load.

When it’s time to upgrade or buy a generator, platforms like Electrical Trader can connect you with suppliers offering equipment tailored to your specific power needs. Choosing the right size generator not only improves efficiency but also helps you save on fuel and maintenance over the long term.

Conclusion

The amount of fuel a generator consumes largely hinges on how it's operated. Key factors that influence its efficiency include managing the load effectively, keeping up with maintenance, accounting for environmental conditions, using high-quality fuel, and ensuring the generator is properly sized for the job. Generators tend to run most efficiently when operating at 70% to 80% of their rated capacity. Straying from this range can lead to issues: running under capacity can cause wet stacking and carbon buildup, while overloading accelerates wear and increases the likelihood of breakdowns. To maintain optimal performance, disciplined maintenance practices are essential.

Routine upkeep - like replacing air filters on schedule, cleaning injectors every 1,000 hours, and changing oil filters every 500 hours - can significantly boost efficiency by improving combustion and reducing internal friction. These small but consistent efforts can lead to noticeable fuel savings over time.

Environmental conditions also play a role in fuel efficiency. For instance, higher altitudes and extreme temperatures can disrupt combustion, leading to higher fuel consumption. Adjustments like using engine preheaters in colder climates can help offset these effects. Tackling such environmental challenges not only improves efficiency but also supports the case for upgrading equipment to meet operational demands.

Modern generators equipped with electronic common-rail injection systems are a game-changer, reducing fuel consumption by 15–20% compared to older designs. When the time comes to replace outdated units or source dependable parts, platforms like Electrical Trader provide access to high-quality power generation equipment and components designed to support long-term efficiency goals.

FAQs

How does the load level of a diesel generator impact its fuel efficiency?

The load level plays a crucial role in determining a diesel generator's fuel efficiency. When a generator operates at light loads - typically below 30–50% of its rated capacity - it consumes more fuel per kilowatt-hour (kWh). This inefficiency can also lead to problems like wet stacking, which negatively impacts the generator's performance over time.

On the other hand, running the generator at around 70–80% of its rated capacity hits the sweet spot for fuel efficiency. At this range, the generator achieves its lowest specific fuel consumption, making it the most cost-effective and efficient way to operate.

Although running the generator at full load might seem like a good idea, it doesn't offer any additional fuel savings and can accelerate wear and tear. To get the most out of your generator, aim to keep it within the ideal load range and perform regular maintenance to prevent unnecessary fuel waste.

How can I reduce fuel consumption in my diesel generator through maintenance?

Proper maintenance plays a crucial role in keeping diesel generator fuel consumption in check. Stick to the manufacturer’s recommended maintenance schedule, which includes routine oil changes and replacing air and fuel filters. This helps ensure the generator runs smoothly, promotes efficient combustion, and avoids wasting fuel.

Pay close attention to the fuel injection system - inspect and clean it regularly to remove carbon buildup and maintain proper atomization. Don’t forget to check for leaks, worn components, or mechanical issues like loose fittings or damaged seals that could lead to fuel loss. Another important tip: run your generator under load (ideally 70–80% of its capacity) at least once a week. This practice prevents problems like wet stacking and keeps the engine functioning at its best.

By staying on top of these maintenance tasks, you not only improve fuel efficiency but also help extend the life of your generator.

How do temperature and altitude affect diesel generator fuel consumption?

Environmental conditions like temperature and altitude play a big role in how much fuel a diesel generator uses. At higher altitudes, the thinner air has less oxygen, which makes combustion less efficient. This forces the engine to work harder, leading to higher fuel consumption. Similarly, hot temperatures can reduce cooling efficiency and lower air density, which adds extra strain on the generator and increases diesel usage.

On the flip side, extremely cold temperatures can cause diesel fuel to thicken or even gel, making it harder for the fuel to flow properly. This means the generator has to expend more energy to function effectively. To counter these challenges, steps like using winter-grade diesel fuel or adjusting the generator for altitude can help maintain better fuel efficiency.