Ultimate Guide to Diesel Generator Performance Metrics

Share

Diesel generator performance metrics are essential for managing costs and ensuring reliability. They help you measure efficiency, fuel consumption, and power output, which directly impact operating expenses and equipment lifespan. Here’s what you need to know:

- Fuel Efficiency: Measured in kWh per gallon, most generators operate at 35–45% efficiency, with optimal performance at 70–80% load.

- Fuel Consumption: Fuel often accounts for over 70% of lifetime operating costs. A 5% efficiency improvement on a 500 kVA generator could save $8,000 annually.

- Load Management: Running below 30% load can cause damage (wet stacking), while overloading increases wear. Aim for 70–80% load for balance.

- Maintenance: Clean filters, functional injectors, and regular servicing improve efficiency and reduce costs.

These metrics ensure generators run efficiently, prevent costly repairs, and maximize performance. Proper sizing, routine maintenance, and performance monitoring are key to achieving these goals.

Test System And Test Steps | Mpmc Diesel Generator | MPMC Powertech Corp

Fuel Efficiency and Consumption

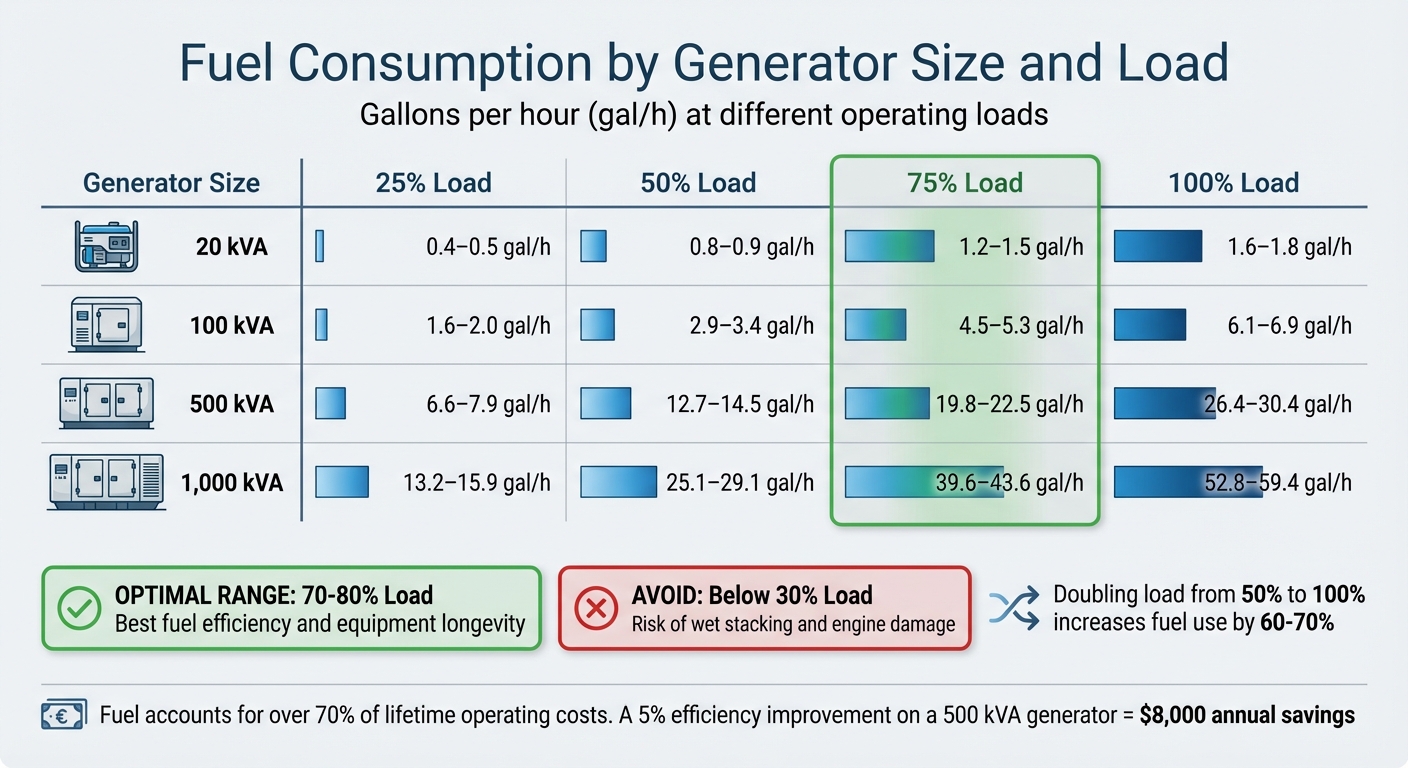

Diesel Generator Fuel Consumption Rates by Size and Load Percentage

Fuel efficiency plays a massive role in controlling operating costs, especially for diesel generators. Fuel consumption alone often makes up over 70% of total lifetime operating costs for these machines. Even a small improvement in efficiency can lead to significant savings. For instance, increasing efficiency by just 5% on a 500 kVA generator could save more than $8,000 annually, based on average diesel prices.

Efficiency Calculation Formula

Understanding how efficiently your generator uses fuel is crucial. A common measure is thermal efficiency, which compares the electrical output to the energy in the fuel consumed. Diesel fuel typically contains 40.9 kWh per gallon (10.8 kWh per liter).

For example, if your generator outputs 280 kWh while consuming 16.4 gallons of diesel:

- Calculate energy input:

16.4 gallons × 40.9 kWh/gallon ≈ 670 kWh. - Determine thermal efficiency:

(280 ÷ 670) × 100 ≈ 41.8% thermal efficiency.

Most modern diesel generators operate with thermal efficiencies between 30% and 40%, though some industrial models can exceed 40% under ideal conditions.

Another key metric is Specific Fuel Consumption (SFC), expressed in liters per kilowatt-hour (L/kWh). Most generators consume between 0.2 and 0.4 L/kWh. A common rule of thumb estimates about 0.1 gallons of fuel per kWh at full load. When calculating efficiency, always use net output - subtracting parasitic loads like cooling systems and controllers, which typically consume 4–8% of total output.

What Affects Fuel Efficiency

Several factors influence how efficiently a generator converts diesel into electricity:

- Load percentage: Generators perform best at 70–80% of their rated capacity. Operating below 40% load can increase fuel consumption per kWh by 15–20%.

- Maintenance: Dirty air filters can cut efficiency by 10%, while worn injectors may cause a 7% drop. Routine tasks like replacing oil filters every 500 hours or cleaning injectors every 1,000 hours can improve performance.

- Environmental conditions: Generators work best at 77°F (25°C). Fuel consumption rises by about 3% for every 9°F (5°C) drop below 50°F (10°C) and by 2% for every 9°F (5°C) increase above 95°F (35°C). High altitudes also impact efficiency, with fuel consumption increasing 6–8% for every 3,280 feet (1,000 meters) of elevation.

- Engine technology: Modern engines with electronic injection systems can use 15–20% less fuel than older mechanical pump designs. In one 2023 comparison, a 150 kW generator with electronic injection consumed 18% less fuel than a 2015 model under identical conditions.

Fuel Consumption at Different Loads

Fuel consumption doesn't scale linearly with load, which is why understanding load behavior is critical for cost control. For example, a generator running at 50% load typically uses 55–65% of the fuel it would need at full load.

| Generator Size | 25% Load | 50% Load | 75% Load | 100% Load |

|---|---|---|---|---|

| 20 kVA | 0.4–0.5 gal/h | 0.8–0.9 gal/h | 1.2–1.5 gal/h | 1.6–1.8 gal/h |

| 100 kVA | 1.6–2.0 gal/h | 2.9–3.4 gal/h | 4.5–5.3 gal/h | 6.1–6.9 gal/h |

| 500 kVA | 6.6–7.9 gal/h | 12.7–14.5 gal/h | 19.8–22.5 gal/h | 26.4–30.4 gal/h |

| 1,000 kVA | 13.2–15.9 gal/h | 25.1–29.1 gal/h | 39.6–43.6 gal/h | 52.8–59.4 gal/h |

A 200 kW generator, for instance, consumes about 2.1–2.6 gallons per hour at 25% load (50 kW output) and 6.9–7.9 gallons per hour at 100% load (200 kW output). Doubling the load from 50% to 100% increases fuel use by roughly 60–70%.

"Choosing the right size of the generator for your intended application is key to keeping fuel use under control." – General Power

To maintain efficiency and reliability, avoid running generators below 30% load for long periods. If your load is consistently low, consider using load-sharing controllers with multiple smaller generators or implementing load banking to keep engines operating in the optimal 70–80% range. One island resort reduced diesel use by 67% by integrating a 200 kW solar array and 500 kWh battery storage with its existing diesel generator, cutting daily consumption from 74 gallons to just 20 gallons.

Power Output and Load Capacity

Power ratings play a critical role in ensuring a generator operates safely and efficiently. The two primary ratings - standby and prime - determine how long and under what conditions a generator can run without exceeding safe limits. Choosing the right rating for your needs not only protects your equipment but also helps control operating costs. Let’s dive into how these ratings differ and why they matter.

Standby Power (ESP)

Standby power is designed specifically for emergency situations, such as utility outages. These generators are not meant for continuous use and typically have annual operating limits ranging from 200 to 500 hours. For example, Caterpillar sets its Emergency Standby Power rating at 200 hours per year, while its standard Standby rating allows up to 500 hours.

Prime Power (PRP)

Prime-rated generators are built for continuous operation in areas with unreliable or no utility power, such as construction sites, remote mining locations, or off-grid facilities. These units often include a 10% overload capacity for up to 1 hour in every 12 hours of operation, though this overload is usually capped at around 25 hours annually. Additionally, prime-rated engines tend to be slightly more fuel-efficient - up to 5% - when running at partial loads compared to standby models.

"Duty rating is not an afterthought - it is central to generator specification. A mismatched rating leads to inefficiency, shortened lifespan, and possible warranty loss." – Jubaili Bros

Using a standby-rated generator for prime applications can lead to faster engine wear and might void the manufacturer’s warranty. As Brandon Kraemer, Senior Product Manager at MTU Onsite Energy, explains:

"Misapplication of these ratings can jeopardize the longevity of the generator set, void manufacturer's warranties and put the set at risk for failure".

On the other hand, using a prime-rated generator for standby purposes could mean overspending on capacity that isn’t necessary.

Prime vs. Standby Power Ratings

The International Organization for Standardization (ISO) 8528-1 specifies that Emergency Standby Power should have a 24-hour average load factor of no more than 70% of the nameplate rating. However, some manufacturers exceed this standard. For instance, MTU allows an 85% average load factor for its ESP-rated generators, and Caterpillar’s Mission Critical rating also supports an 85% load factor, making these options suitable for facilities like hospitals and data centers that demand highly reliable backup power.

| Rating Type | Max Annual Hours | Average Load Factor | Overload Capability | Typical Use |

|---|---|---|---|---|

| Standby (ESP) | 200–500 hours | 70%–85% | None | Hospital backup, data center UPS |

| Prime (PRP) | Unlimited | 70%–75% | 10% (1 hr per 12 hrs) | Remote mining, construction sites |

| Continuous (COP) | Unlimited | 70%–100% | None | Baseload power plants |

To ensure your generator meets your needs, analyze your load profile, including minimum, average, and peak demands. If your average utilization exceeds 70–80%, a Prime or Continuous rating is likely a better fit. Beyond ISO standards, check with manufacturers for specialized ratings like "Mission Critical" or "Data Center", which may allow higher load factors while still meeting standby requirements.

Load Factor and Operating Range

Load factor is another key consideration. It represents the average load on your generator compared to its nameplate rating over a 24-hour period. Operating outside the recommended load factor can reduce efficiency, shorten the generator’s lifespan, and potentially void warranties.

Soft-loading techniques can help reduce surge demands, allowing smaller generators to operate at higher load factors and ultimately lowering costs. As Brandon Kraemer notes:

"The result [of soft-loading] is smaller generator sets, running at a higher average load factor, for a better total cost to the owner".

Emergency Standby units, designed for short-term use, often have the shortest Time Between Overhaul (TBO). This highlights the importance of selecting a generator rating that matches your actual usage patterns - not just for immediate performance but also for long-term maintenance savings.

For Prime-rated generators used in peak shaving or base loading, intelligent switchgear can monitor power flow to ensure the unit operates within its intended rating. If utility paralleling is part of your plan, make sure your generator has a Prime or Continuous rating, as standby generators aren’t designed for continuous operation in these configurations.

Lastly, don’t overlook environmental factors like altitude and temperature. Use manufacturer-provided derating curves to adjust your power output expectations and ensure reliable performance in your specific conditions.

Transient Performance and ISO 8528-5 Standards

Diesel generators need to stabilize voltage and frequency quickly during sudden load changes. This ensures reliable power delivery and prevents damage to connected equipment, especially in systems sensitive to power fluctuations. The ISO 8528-5 standard outlines performance requirements for generating sets, while ISO 8528-6:2023 specifies the test methods to verify compliance with these requirements.

These standards create a unified framework for comparing generator performance across manufacturers. By standardizing specifications, they eliminate inconsistencies and make it easier for customers to evaluate options. Electrical engineer Suhas Ghatnekar highlights the importance of these standards:

"The ISO has developed a standard set of power rating definitions to avoid confusion... to provide consistency across manufacturers and industries and to improve communication and understanding between the manufacturer and the customer".

ISO 8528-5 Performance Classes

ISO 8528-5 divides generators into performance classes - G1, G2, G3, and G4 - based on how well they handle voltage and frequency during steady-state and transient conditions. These classifications specify how quickly a generator can recover and the acceptable levels of voltage and frequency deviation after a load change. The standard evaluates the entire generator set, ensuring all components work cohesively to meet performance goals. For critical applications, such as hospitals or high-rise buildings, ISO 8528-6 serves as a foundation for setting additional performance benchmarks.

The latest update, ISO 8528-6:2023, introduces simulation methods as an acceptable way to verify compliance with ISO 8528-5. Published in November 2023, this 65-page document gives manufacturers more flexibility while maintaining strict performance standards.

Load Acceptance and Response Time

The method used to apply a load plays a significant role in response time. Soft-loading techniques reduce the initial power demand and help the generator stabilize more quickly. On the other hand, single-step loading creates an immediate, high demand, pushing the generator to its maximum transient response capability.

Several factors influence a generator's ability to accept and respond to loads, including engine size, the design of the fuel system, and the cooling system. For standby generators, maintaining engine temperature with jacket water heaters can improve cold starts, reduce wear, and minimize smoking during initial operation.

To prevent engine damage and ensure proper combustion, generators should run at a minimum of 30% load. It's also essential to evaluate performance based on net power, which accounts for the energy consumed by the cooling system.

sbb-itb-501186b

Performance Benchmarks and Efficiency Curves

Efficiency Curves by Load Percentage

A diesel generator's efficiency curve maps electrical power output against fuel energy input, helping identify the sweet spot for performance - where output per gallon of fuel is maximized. For most diesel generators, this optimal range is between 70% and 80% of their rated load. Modern industrial units can achieve efficiencies exceeding 40% under ideal conditions, though the typical range is between 35% and 45%. Straying outside the 70–80% range often leads to reduced performance and problems like wet stacking, which not only hurts efficiency but can also damage the engine. Running at full capacity (100%) keeps efficiency relatively high but increases both fuel consumption and mechanical wear.

Let’s break this down with an example: a 200 kW generator. At a low 25% load, fuel consumption hovers around 2–3 gallons per hour, resulting in poor efficiency. At the optimal 75% load, fuel use rises to 5–6 gallons per hour, providing the best balance between fuel usage and output. At full load (100%), the generator typically consumes 7–8 gallons per hour, but the added mechanical strain becomes a concern.

These efficiency insights are essential for comparing generator performance against industry benchmarks.

Industry Standard Metrics Comparison

Efficiency curves serve as a foundation for benchmarking generator performance against established standards. ISO 8528-1:2005 is the go-to guideline for comparing generators across manufacturers. Some brands outperform these baseline standards. For example, MTU Onsite Energy allows an 85% 24-hour average load factor for its ESP-rated units - 15% above the ISO minimum. On the other hand, Caterpillar sets a stricter limit, recommending a maximum average load factor of 70% for its Standby and Prime-rated generators.

Here’s a quick comparison of typical ratings and their efficiency benchmarks:

| Rating Type | Annual Hours | Load Factor | Typical Efficiency Range | Ideal Application |

|---|---|---|---|---|

| Emergency Standby (ESP) | 200–500 hours/year | 70% (up to 85% for MTU) | 35–40% at rated load | Utility outage backup |

| Prime Power (PRP) | Unlimited | 70–75% | 38–43% at optimal load | Remote sites, mining |

| Continuous (COP) | Unlimited | 70–100% | 40–45% at steady load | Base load power stations |

| Mission Critical | 500 hours/year | 85% | 38–42% at rated load | Data centers, hospitals |

When evaluating generator models, it’s crucial to confirm whether the ratings reflect net power - which factors in the cooling system's energy usage - or gross engine output. This distinction can significantly affect real-world performance and the cost per kilowatt-hour. To ensure accuracy, consider installing calibrated fuel and kilowatt meters. These tools can monitor efficiency and help pinpoint issues like injector wear or subpar fuel quality before they escalate into expensive repairs.

Measurement and Optimization Methods

Improving generator performance starts with precise measurement and regular maintenance, both of which are essential for achieving consistent efficiency.

How to Measure Efficiency Accurately

To measure generator efficiency, track both fuel flow and electrical output simultaneously. This allows you to calculate the real-time conversion rate. Install calibrated fuel flow meters alongside digital kilowatt meters on each unit to determine the cost per kilowatt-hour and pinpoint areas of inefficiency.

Conduct load bank testing at various staged loads - 25%, 50%, 75%, and 100% - to establish a performance baseline. For compliance with NFPA 110 standards, standby generators should be run monthly for at least 30 minutes at a load of 30% or higher, while maintaining voltage regulation within ±5% of the nominal output.

IoT-enabled monitoring systems can provide continuous data, which is invaluable for maintaining optimal performance. These systems track fuel use and output in real time, offering insights that can quickly offset their implementation cost - especially since fuel represents over 70% of total operating expenses. For accurate comparisons, adjust readings to account for fuel temperature and density.

How Maintenance Affects Performance

Accurate measurement is only part of the equation - routine maintenance is equally important for sustaining efficiency. Regular upkeep not only enhances fuel efficiency but also extends the generator's lifespan. Tasks like keeping filters clean, ensuring proper valve settings, and maintaining functional injectors help reduce fuel consumption and operating costs. Generators adhering to strict maintenance schedules often surpass 25,000 hours of operation before needing major overhauls. As noted by the U.S. Department of Energy:

"Routine maintenance is the single most effective way to extend generator life, improve fuel efficiency, and maintain emissions compliance."

Stick to manufacturer-recommended schedules for oil changes, filter replacements, and battery checks. Use the "greater of two" rule - perform maintenance based on whichever occurs first: engine run hours or calendar age (e.g., 250 hours or six months). Battery performance is another critical factor; annual load testing and replacing batteries every 2–3 years can significantly reduce start failures.

Monthly exercise runs at a minimum of 30% load help avoid wet stacking, a condition where unburned fuel and carbon build up in the exhaust system, leading to reduced efficiency. Annual load-bank testing at full capacity (100%) is also recommended to burn off these deposits and confirm that cooling and fuel systems are functioning properly. Lastly, maintaining a detailed service log that tracks operating hours, load levels, and maintenance tasks can help identify long-term performance trends and even boost the generator's resale value.

Conclusion

Tracking and understanding diesel generator performance metrics isn’t just about meeting technical standards - it’s about protecting your investment and cutting costs. With fuel often being one of the largest operating expenses, even small improvements in efficiency can lead to noticeable savings. Keeping an eye on fuel consumption and electrical output helps you calculate the true cost per kilowatt-hour and quickly identify inefficiencies.

Operating your generator within 70% to 80% of its rated capacity is key. This range ensures better fuel efficiency, prevents issues like wet stacking, and extends the engine’s lifespan. As Brandon Kraemer, Senior Product Manager at MTU Onsite Energy, explains:

"Misapplication of these ratings can jeopardize the longevity of the generator set, void manufacturer's warranties and put the set at risk for failure".

Running below 30% load for extended periods can lead to unburned fuel buildup, which directly impacts efficiency.

Right-sizing your generator is just as important as running it properly. Choosing a unit that matches your specific duty cycle avoids unnecessary wear and wasted resources. An oversized generator running at low loads drives up costs through inefficiency and extra maintenance, while an undersized one can fail under peak demand.

To bridge technical performance with cost control, regularly measure performance using calibrated fuel and kilowatt meters, and conduct load bank testing. Pair these practices with a solid maintenance schedule to extend your generator’s lifespan. Proper documentation is also crucial for meeting regulatory requirements like NFPA 110, especially for critical facilities such as hospitals and data centers.

Whether you’re purchasing new equipment or fine-tuning what you already have, focusing on these metrics ensures your diesel generators provide reliable power while keeping costs in check. Monitor your metrics, maintain your equipment, and operate within its design limits - this approach reduces fuel expenses and extends the life of your generator. By aligning operation, measurement, and maintenance, you’ll achieve better performance and smarter cost management.

FAQs

What are the best ways to improve the fuel efficiency of a diesel generator?

Improving the fuel efficiency of your diesel generator boils down to a few smart practices. First, load management is key. Running your generator within its optimal load range - typically around 70-80% - helps ensure fuel is used effectively. It also prevents problems like wet stacking, where unburned fuel builds up and drags down efficiency.

Another crucial factor is regular maintenance. Keep up with oil changes, engine servicing, and always opt for high-quality fuel. This not only promotes cleaner combustion but also reduces wear and tear on the engine. It’s also essential to use a generator that’s properly sized for your power needs. Overloading or underloading can lead to unnecessary fuel waste and reduced performance.

If your generator is often subjected to fluctuating power demands, you might want to explore variable speed models. These adjust the engine speed based on the load, which can lead to noticeable fuel savings. By combining these approaches, you’ll not only improve performance but also cut down on fuel expenses.

What happens if you run a diesel generator at low load levels?

Operating a diesel generator at low load levels - generally below 30-40% - can cause a range of problems. These include lower efficiency, added strain on mechanical parts, and the potential for wet stacking. Wet stacking happens when unburned fuel and soot build up in the exhaust system. Over time, this leads to engine deposits, increased maintenance expenses, and even a reduced lifespan for the generator.

To keep your generator running smoothly and for as long as possible, aim to operate it within its recommended load range whenever feasible.

How can I determine the right generator size for my power needs?

To determine the right generator size, start by calculating your total power requirements. Make a list of all the devices and appliances you intend to run and add up their wattages. To ensure smooth operation and allow for future needs or startup surges, add an extra 20% buffer to your total.

You’ll also want to understand the distinction between real power (kW) and apparent power (kVA). Most generators operate with a power factor of 0.8. For example, if your total load is 10 kW, you’ll need a generator rated at least 12.5 kVA (10 kW ÷ 0.8).

Other considerations include the type of load (like motors or lighting), the environment in which the generator will operate, and any plans for future expansion. For the most accurate sizing, review the manufacturer’s specifications or consult a generator expert to ensure the unit can meet your needs without issues.