Transformer Oil Dielectric Strength Testing Guide

Share

Transformer oil is critical for insulation and cooling in transformers, but its quality can degrade over time due to moisture, contaminants, and oxidation. Regular dielectric strength testing helps ensure the oil's ability to withstand electrical stress and prevent failures. This guide covers:

- What dielectric strength and Breakdown Voltage (BDV) mean: BDV measures the voltage at which oil fails to insulate.

- Why BDV testing matters: Low BDV often signals moisture or contamination, risking transformer breakdown.

- Testing process: Collect an oil sample, prepare it properly, and test using standards like ASTM D877, ASTM D1816, or IEC 60156.

- Key equipment: High-voltage testers, spherical electrodes, and proper sampling tools.

- Interpreting results: New oil should exceed 35 kV; in-service oil below 30 kV needs attention.

- Fixing low BDV: Solutions include filtration, vacuum degassing, or complete oil replacement.

Routine testing, ideally twice a year, can extend transformer life and avoid costly outages. Keep reading for step-by-step instructions, standards, and troubleshooting tips.

What is Dielectric Strength and Breakdown Voltage (BDV)?

Dielectric Strength Defined

Dielectric strength refers to the maximum electric field a transformer oil can endure before it breaks down. For mineral-based transformer oils, this typically falls between 10–15 MV/m.

"Dielectric strength is defined as the maximum voltage required to produce a dielectric breakdown through a material, expressed as Volts per unit thickness." - ScienceDirect

When this limit is exceeded, the oil loses its insulating properties, allowing electrical arcing between components. This insulating barrier is essential to prevent transformer failures. Understanding dielectric strength lays the foundation for grasping how breakdown voltage testing evaluates the oil's quality.

Why Breakdown Voltage (BDV) Matters

Breakdown voltage (BDV) builds on the concept of dielectric strength, pinpointing the exact voltage at which transformer oil fails under electrical stress. Essentially, BDV is the voltage at which the oil no longer insulates and a spark jumps between electrodes. During testing, engineers gradually increase the AC voltage between two electrodes spaced 0.1 inches (2.5 mm) apart until an arc forms. The voltage rises steadily at 2 kV per second, and the average of 5–6 test runs determines the BDV.

BDV is a critical indicator of contamination. For instance, just 0.06% water in the oil can cut its dielectric strength by nearly half. Contaminants like dirt, cellulosic fibers, and conductive particles also lower BDV readings. For transformers in operation, maintaining a BDV above 28 kVRMS is vital - readings below 30 kV for a 4 mm gap strongly suggest moisture issues.

"The dielectric breakdown voltage of an insulating liquid is of importance as a measure of the liquid's ability to withstand electric stress without failure." - ASTM International

Routine BDV testing helps detect oil degradation early, preventing internal arcing, equipment fires, or catastrophic transformer failures. Testing at least twice a year can significantly extend your transformer's lifespan and help avoid costly emergency replacements.

Required Tools and Equipment for BDV Testing

High-Voltage Breakdown Testers

High-voltage breakdown testers are essential for BDV testing. These devices apply an increasing AC voltage between electrodes immersed in the oil until a spark forms, cutting off the circuit. Most modern testers offer voltage ranges from 0 to 80 kV, with some high-performance models reaching up to 100 kV. They also feature adjustable voltage rise rates, typically ranging from 0.5 to 5.0 kV per second.

When choosing a tester, consider fully automatic models. These devices handle the entire test process, including stirring, standing time, and multiple test cycles, all while adhering to pre-programmed international standards like IEC 60156, ASTM D877, and ASTM D1816. Many models come equipped with advanced safety features such as over-current protection and automatic shutdown. Additional conveniences include touch screens, internal memory for storing up to 100 test results, and built-in thermal printers for immediate documentation on-site. These features make them compatible with automated testing protocols required by international standards.

Oil Sampling and Preparation Tools

Accurate BDV testing starts with proper sampling techniques. Use an "oil thief" to extract oil from the bottom layer of the container, where water and sludge tend to accumulate. It's best to collect samples in glass syringes or bottles with caps lined with tin or aluminum foil to prevent contamination from plastic materials.

You'll also need spherical electrodes (12.5–13 mm in diameter) and a standard thickness gauge to set the electrode gap. The gap is typically 2.5 mm for IEC 60156 tests and 4 mm for ASTM D877 or ASTM D1816 standards. For cleaning the electrodes, use lint-free cloths to avoid introducing fibers that could compromise the sample. Before collecting the sample, rinse the bottle with the test oil to ensure cleanliness. Once the test cell is filled, allow the oil to stand for 10 to 20 minutes. This resting period helps any trapped air bubbles escape, ensuring accurate results.

BDV Test of Transformer Oil. Breakdown Voltage Test or Di-electric Strength Test of Insulating Oil.

How to Perform BDV Testing: Step-by-Step Process

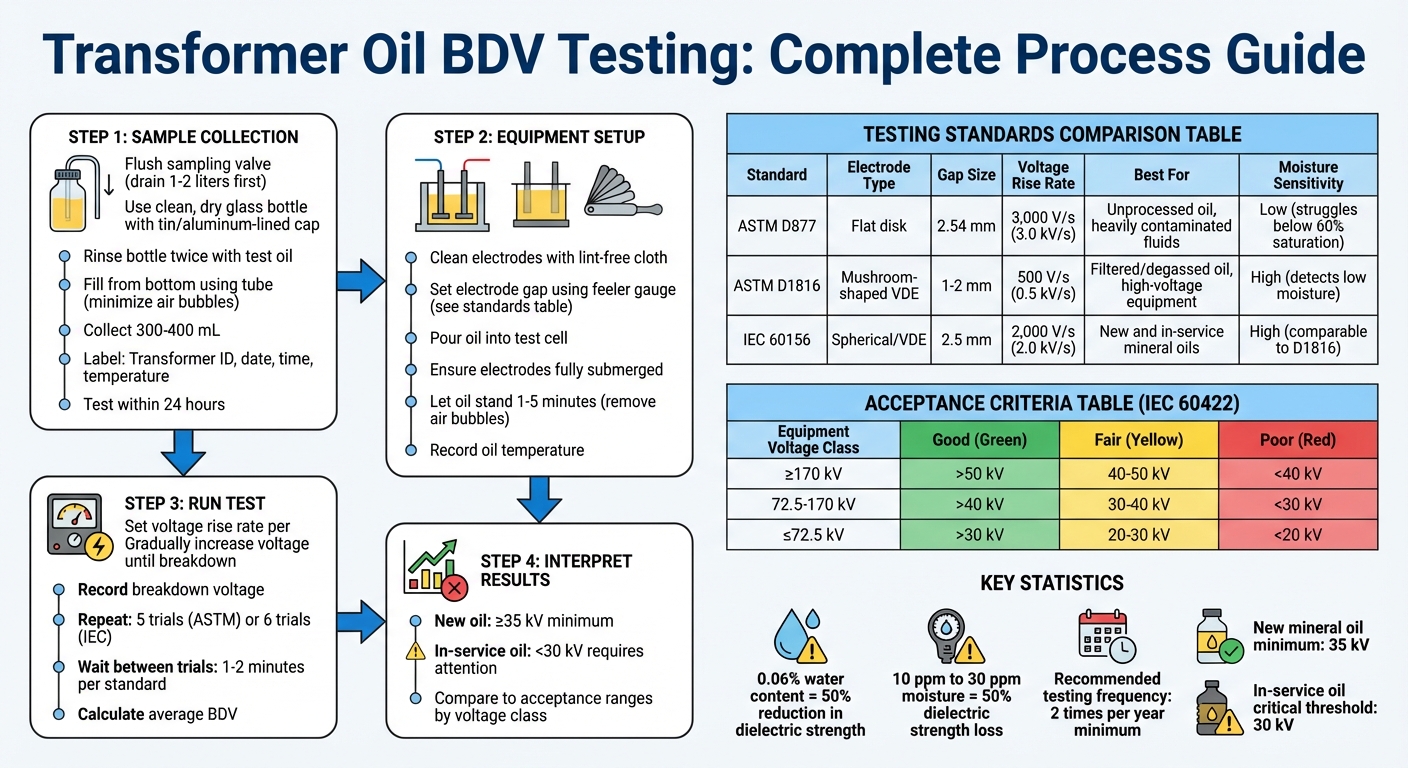

Transformer Oil BDV Testing Step-by-Step Process and Standards Comparison

Collecting and Preparing Oil Samples

Start by flushing the transformer tank's sampling valve to clear out any sediment or moisture. Drain about 1–2 liters of oil before collecting your sample . Use a clean, dry glass bottle with a tin- or aluminum-lined cap for the sample. To ensure accuracy, rinse the bottle twice with the oil before filling it. When collecting, use a tube to fill the bottle from the bottom - this helps minimize air bubbles. Aim to collect 300–400 mL of oil. Once done, seal the bottle tightly and label it with the transformer ID, date, time, and temperature. For the most reliable results, conduct the test within 24 hours of sample collection.

Keep in mind that moisture significantly affects the dielectric strength. For example, increasing moisture content from 10 parts per million (ppm) to 30 ppm can cut the dielectric strength in half. Also, avoid using cotton waste or other fibrous materials during the process, as lint particles can interfere with the test by bridging the electrode gap, leading to inaccurately low readings.

Setting Up and Calibrating Test Equipment

Once the oil sample is ready, it's time to set up and calibrate the test equipment. Start by cleaning the electrodes with a lint-free cloth to remove any contaminants. Carefully align them and use a feeler gauge to set the electrode gap. The gap should be adjusted based on the standard you're following: 2.54 mm for ASTM D877, 1–2 mm for ASTM D1816, or 2.5 mm (±0.05 mm) for IEC 60156 .

Pour the oil into the test cell, ensuring the electrodes are fully submerged and no air bubbles remain. Let the oil sit undisturbed for 1–5 minutes (depending on the standard) to allow any trapped air to escape. Before proceeding, measure and record the oil temperature, as higher temperatures can lower its dielectric strength .

Running the Test and Recording Results

With the test cell prepared, you can begin the BDV test. Set the voltage rise rate according to the standard you're using: 3.0 kV/s for ASTM D877, 0.5 kV/s for ASTM D1816, or 2.0 kV/s for IEC 60156. Gradually increase the voltage until a breakdown occurs, and record the breakdown voltage. If you notice sizzling sounds or bubble formation, it may indicate high moisture content in the oil .

Repeat the test multiple times: five trials for ASTM standards or six for IEC standards. Allow the required time between breakdowns - 1 minute for ASTM D877, 1 to 1.5 minutes for ASTM D1816, and 2 minutes for IEC 60156. After completing the trials, calculate the average BDV value. For reference, new mineral oil should typically have a dielectric strength of at least 35 kV. For in-service transformers, a reading below 30 kV is generally considered inadequate .

sbb-itb-501186b

Industry Standards and Acceptable BDV Values

BDV Testing Standards: ASTM D877, ASTM D1816, and IEC 60156

Industry standards play a crucial role in defining acceptable breakdown voltage (BDV) thresholds for transformer oil. Three key standards guide BDV testing, each with unique electrode designs and testing parameters.

ASTM D877, one of the earliest methods, uses flat disk electrodes with a 2.54 mm gap and a voltage rise rate of 3,000 V/s. This method is mainly used for unprocessed oil supplied by vendors or heavily contaminated fluids from circuit breakers and load tap changers. However, it struggles to detect low levels of moisture unless the oil is more than 60% saturated.

On the other hand, ASTM D1816 employs mushroom-shaped VDE electrodes with a smaller 1–2 mm gap and a slower voltage rise rate of 500 V/s. This method is far more sensitive to small amounts of moisture and cellulosic fibers, making it the preferred choice for filtered and degassed oil used in high-voltage equipment. Additionally, it requires a two-bladed impeller to keep contaminants suspended, mimicking the dynamic conditions inside an operating transformer.

The international standard, IEC 60156, uses spherical or VDE-like electrodes with a 2.5 mm gap and a voltage rise rate of 2,000 V/s. Its sensitivity is comparable to ASTM D1816, and it is widely applied to both new and in-service mineral oils. This method generally produces higher BDV readings compared to ASTM standards.

For filtered and degassed oil, ASTM D1816 is often preferred over ASTM D877 because D877 can produce misleadingly high readings by failing to detect low moisture levels. Notably, ASTM D877's sensitivity drops significantly when test voltages exceed 25 kV rms. These standards provide the foundation for determining acceptable BDV results.

How to Read Test Results and BDV Acceptance Ranges

Interpreting BDV values is essential for assessing transformer oil quality. Acceptable BDV levels depend on the equipment's voltage class and the oil's condition. For new mineral oil, IEC 60156 specifies a minimum BDV of over 40 kV for equipment rated at 72.5 kV or below, and over 60 kV for equipment rated at 170 kV or higher. Bulk mineral oil should meet a minimum BDV of 30 kV as per IEC 60296, which should increase to at least 70 kV after laboratory vacuum filtration.

For in-service oil tested with ASTM D877, transformers rated above 69 kV should maintain a minimum BDV of 30 kV, while those rated at 69 kV or below should have at least 25 kV. Circuit breakers, meanwhile, require a minimum BDV of 25 kV. The IEC 60422 standard provides more detailed guidelines based on voltage class and oil condition:

| Equipment Voltage Class | Good | Fair | Poor |

|---|---|---|---|

| ≥ 170 kV | > 50 kV | 40–50 kV | < 40 kV |

| 72.5 kV to 170 kV | > 40 kV | 30–40 kV | < 30 kV |

| ≤ 72.5 kV | > 30 kV | 20–30 kV | < 20 kV |

Monitoring trends in BDV values over time is just as important as evaluating absolute numbers. As Kori Jenkins from SDMyers points out:

"A trend downward in the D877 value over time may also indicate the beginning of an abnormal condition or a contamination problem even if the values continue to be acceptable".

If BDV results fall into the "Fair" or "Poor" categories, further tests - such as moisture content analysis, particle count, and acid number evaluation - should be performed before considering oil reconditioning. These steps are critical to preserving the insulation integrity of transformers, as discussed earlier.

It's worth noting that many dielectric meters cap their readings at 60 kV, which can be a limitation for high-voltage installations where BDV levels may exceed this range. To ensure reliable and reproducible results, oil should always be tested at room temperature (around 68°F to 86°F) instead of being tested directly after processing or while in service.

Fixing Low BDV Results: Diagnosis and Solutions

What Causes Low BDV in Transformer Oil

The main culprit behind low Breakdown Voltage (BDV) in transformer oil is moisture contamination. Even a small amount of water can significantly impair the oil's insulating properties. Anne Reygaerts from Laborelec emphasizes this point:

"Any increase in moisture content can reduce the insulating properties of the oil, which may result in dielectric breakdown" – Anne Reygaerts, Laborelec.

But moisture isn't the only issue. Particulate matter, like sediments or metallic particles from corrosion, can create conductive paths for electrical arcs. Over time, oil aging and oxidation produce polar contaminants, organic acids, and sludge, all of which degrade performance. Temperature swings can further weaken the oil by increasing molecular activity, while the breakdown of cellulose materials inside the transformer releases moisture, acids, and furans into the oil.

Additional Tests for Problem Diagnosis

Before diving into extensive diagnostics, it's wise to resample the oil to rule out sampling errors. As Power Transformer Health advises:

"The first step is to identify the root cause of the low dielectric strength – common causes are usually a bad oil sample. A resample is always recommended".

If the issue persists after resampling, additional tests can help pinpoint the problem. These include:

- Karl Fischer titration to measure moisture levels.

- Acidity testing to detect corrosive contaminants.

- Interfacial tension measurements to identify polar contaminants.

- Dissolved gas analysis to uncover internal faults.

Other valuable tests include Tan Delta (for insulation quality), furan analysis (to assess cellulose degradation), and particle counting, which typically checks for particles in the 3–150 μm range per 10 mL of oil. Once the root cause is clear, you can move forward with targeted solutions to restore the oil's performance.

Methods to Restore Oil Quality

Once the cause of low BDV is identified, several methods can be used to restore the oil's quality:

- Oil filtration: Removes solids and sediments. Online filtration is particularly useful as it allows treatment without de-energizing the transformer. However, care must be taken to avoid over-drying the oil.

- Vacuum degassing: Extracts dissolved gases and moisture, improving the oil's insulating properties.

- Complete oil replacement: For smaller transformers, replacing the oil entirely may be the most practical and cost-effective way to eliminate contaminants and aging byproducts.

To prevent future issues, schedule regular tests for moisture, BDV, and acidity. Additionally, periodic inspections for leaks or problems with the breathing system can help catch early signs of degradation and keep the transformer running smoothly.

Conclusion

BDV testing plays a vital role in assessing transformer insulation and preventing electrical arcing. As highlighted by oil‐tester.com:

"The dielectric strength of transformer oil is a paramount indicator of its ability to perform its primary insulating function within high‐voltage electrical apparatus".

Without routine BDV testing, contaminants like moisture, particles, and oxidation can quietly degrade the insulation, leading to potential failures.

The numbers speak for themselves. An increase in moisture from 10 ppm to 30 ppm can cut the dielectric strength in half. Similarly, just 0.06% water content can reduce insulation capacity by about 50%. To stay ahead of such risks, it's recommended to conduct at least two BDV tests annually.

When performing tests under standards like ASTM D1816, D877, or IEC 60156, it's essential to draw samples from the bottom valve, use properly calibrated equipment with a 2.5 mm ± 0.05 mm electrode gap, and conduct multiple tests (e.g., six tests as per IEC 60156) to ensure accurate results.

If BDV readings fall below 30 kV, immediate action is required. This could involve filtration, vacuum degassing, or even replacing the oil, depending on the diagnostics. Tracking BDV trends over time is equally important, and automated testers can improve consistency and reliability in measurements.

FAQs

How often should the dielectric strength of transformer oil be tested?

The dielectric strength of transformer oil is typically tested annually to ensure it retains its insulating capabilities and continues to safeguard the transformer. However, for older transformers or those operating under high-risk conditions, more frequent testing may be necessary to catch early signs of deterioration and avoid potential failures.

Routine testing plays a crucial role in detecting contamination, moisture, or aging within the oil - factors that can negatively impact the transformer's performance and safety. Be sure to follow industry standards and the manufacturer's guidelines to determine the appropriate testing schedule for your equipment.

What are the warning signs that transformer oil needs immediate maintenance after BDV testing?

Transformer oil needs prompt attention if its breakdown voltage (BDV) falls below recommended levels. For instance, this could be under 20 kV at a 1 mm gap, 35 kV at a 2 mm gap (as outlined in ASTM D1816), or 30 kV at a 4 mm gap. A sudden drop in BDV might signal problems such as excessive moisture or contamination from solid particles.

Addressing these issues quickly is essential to ensure the transformer operates efficiently and to avoid potential damage.

What other tests should be done if the transformer oil's dielectric strength (BDV) is low?

If the dielectric strength (BDV) of transformer oil is low, additional tests can help pinpoint the root cause. Start by analyzing the water content, acidity, and sludge levels, as these can have a major impact on the oil's performance. Performing a dissolved gas analysis (DGA) is also essential, as it identifies gases generated by the degradation of insulation or oil.

Other important tests include evaluating the tan δ (dissipation factor), resistivity, interfacial tension (IFT), flash point, density, viscosity, and pour point. For a deeper understanding, consider conducting a furan analysis to assess the aging of paper insulation. Additionally, check for contaminants like PCBs or corrosive sulfur compounds (e.g., DBDS). Together, these tests offer a detailed picture of the oil’s condition and guide the necessary corrective measures.