How Thermal Expansion Affects Busbars

Share

When busbars heat up due to electrical current, they expand - a process called thermal expansion. This can weaken connections, increase resistance, and cause mechanical stress, leading to system failures. Copper and aluminum, the two main materials used in busbars, behave differently under heat. Copper expands less and handles stress better, while aluminum is lighter and cheaper but expands more, requiring careful design to avoid issues.

Key takeaways:

- Thermal expansion can loosen joints, degrade insulation, and reduce efficiency.

- Copper has a lower expansion rate and higher strength, making it more stable.

- Aluminum is lighter and cost-effective but needs extra measures to manage expansion.

- Strategies like flexible designs, proper material selection, and surface treatments help mitigate these problems.

Understanding and managing thermal expansion is critical for reliable busbar performance.

How Thermal Expansion Works in Busbars

What Is Thermal Expansion?

Thermal expansion refers to the change in a material's size relative to temperature changes. When a material heats up, its atomic kinetic energy increases, causing the atoms to spread apart, which results in expansion.

For busbars, this expansion can be calculated using the formula: ΔL = αL₀ΔT, where:

- ΔL is the change in length

- α is the coefficient of linear thermal expansion

- L₀ is the original length

- ΔT is the temperature change

Dr. Bhargav Raval, a Materials Scientist, explains the significance of this phenomenon:

CTE measures how much a material expands or contracts in response to temperature variations... even little dimensional changes can result in large stresses that will jeopardize the structural integrity and operation of the material.

The material used in busbars plays a critical role in determining how they respond to thermal expansion.

Materials Used in Busbar Construction

Copper and aluminum are the most common materials for busbars, and they behave quite differently when it comes to thermal expansion. Copper, with its electrical conductivity of about 58 MS/m, outperforms aluminum's 37 MS/m. This higher conductivity means copper generates less heat during operation, reducing the risks associated with thermal expansion.

However, aluminum's lightweight nature makes it ideal for applications like aerospace and automotive sectors. On the other hand, copper's durability and mechanical strength make it the go-to choice for essential infrastructure, such as data centers and telecommunications systems. These material properties directly influence how busbar systems withstand repeated thermal cycles over time.

Coefficient of Thermal Expansion (CTE)

The Coefficient of Thermal Expansion (CTE) measures how much a material expands or contracts with temperature changes. Materials with a lower CTE are better at maintaining dimensional stability, which is essential for ensuring reliable electrical connections over the long term.

Copper and aluminum differ significantly in this regard. Copper has a CTE of approximately 9.8 × 10⁻⁶ /°F (or 16.6 × 10⁻⁶ /K), while aluminum's CTE is about 13.1 × 10⁻⁶ /°F (or 21–24 × 10⁻⁶ /K). This means aluminum expands and contracts roughly 34% more than copper under the same temperature changes. As Approved Sheet Metal points out:

Aluminum has a higher thermal expansion coefficient than copper. For this reason, aluminum busbars might expand and contract more with temperature changes, which can lead to unstable connections and even mechanical failures.

This difference is particularly important at joints and connection points, where the mechanical stress from thermal cycling is most pronounced.

Busbar Thermal Analysis - Ansys Maxwell & Icepak - One and Two-Way Coupling

How Thermal Expansion Damages Busbars

When busbars go through repeated cycles of heating and cooling, they endure damage that can weaken their structural integrity and electrical performance. Recognizing these failure mechanisms is crucial to avoiding costly downtime and potential safety risks.

Damage to Joints and Connection Points

In any busbar system, the connection points are the most vulnerable. With each heating and cooling cycle, busbars expand and contract, creating mechanical stress that gradually loosens bolts, nuts, and other fasteners at the joints. As these connections loosen, contact resistance increases, leading to greater power loss. This relationship follows the formula P = I²R₍c₎, where even a slight rise in resistance generates significant heat.

For example, in June 2019, Professor Adrian Plesca from the Gheorghe Asachi Technical University of Iasi studied a copper busbar carrying 1,300A. His findings revealed that when contact resistance at terminals rose from 5 μΩ to 10 μΩ, the temperature difference at junction points exceeded 90°F (32°C) under high current. At 1,600A, this seemingly minor resistance increase caused localized "hot spots", creating a destructive feedback loop of thermal expansion and further damage.

This cycle of heat and stress accelerates the deterioration of connections, as rising resistance generates even more heat. Over time, this process also degrades the surface plating at joints, compounding the problem. Beyond the connections, thermal cycling also takes a toll on the busbar material itself.

Physical Deformation and Wear

Thermal cycling doesn’t just affect the joints - it also impacts the busbar material directly. The constant expansion and contraction lead to material fatigue, which can result in small cracks, permanent warping, and deformations that strain insulators and support structures.

Insulation, a critical component of busbar systems, is especially at risk. Sebastiaan de Boodt, Manager of Product Development at Rogers Corp, explains:

Insulation brittleness/cracking is the most common failure over a long lifetime that is dependent on operating conditions, which can lead to an electrical break down and system failure.

Take PET (polyester) insulation as an example. Typically rated for 221°F (105°C), it can last about 25 years when operating at 176°F (80°C). However, excessive heat accelerates the cross-linking process in the material, causing it to become brittle and prone to cracking. Additionally, areas with reduced cross-sectional conductor area - like tabs or mounting holes - become hot spots, further hastening wear and degradation.

Changes in Electrical Performance

Thermal expansion doesn’t just cause mechanical damage; it also affects electrical performance. As copper or aluminum heats up, its electrical resistivity increases, leading to higher voltage drops and reduced efficiency. The Copper Development Association advises against temperature rises above 65°C (149°F), as they are inefficient. Ideally, busbar systems should aim for temperature rises of no more than 30°C (54°F) above ambient conditions.

When thermal expansion loosens connections and raises contact resistance, the system experiences a cascade of issues: higher resistance generates more heat, which leads to more expansion and further connection degradation. In high-current applications, this deterioration can happen quickly. Additionally, the AC skin effect concentrates current near the surface of the conductor, reducing its effective conduction area and compounding the performance losses.

sbb-itb-501186b

How to Prevent Thermal Expansion Problems

Thermal expansion can cause significant damage if not properly managed. The key is to design systems that accommodate movement, reduce operating temperatures, and protect critical connection points from the stress of repeated heating and cooling. Here are some effective strategies to address thermal expansion challenges.

Expansion Joints and Flexible Designs

Incorporating expansion joints and flexible busbars is one of the most effective ways to deal with thermal expansion. Flexible busbars, made from multiple thin copper strips or braided conductors, can bend and move with temperature changes and vibrations during operation. This design is particularly useful in electric vehicles and machinery, where both thermal and mechanical stresses are common.

Unlike solid busbars, which transfer expansion forces to bolts and terminals - leading to wear and loosening - flexible designs absorb these stresses. Additionally, installing busbars vertically instead of horizontally can improve natural convection, increasing the total heat transfer coefficient by 20%. This enhanced cooling reduces temperature rise, which is a major driver of thermal expansion.

Selecting Materials with the Right CTE

Material selection plays a critical role in managing thermal expansion. Copper's lower coefficient of thermal expansion (CTE) minimizes joint stress, making it a reliable choice for many applications. On the other hand, aluminum, with its higher CTE, requires additional measures like expansion joints and specialized hardware. For instance, Belleville washers help maintain consistent pressure as aluminum expands and contracts.

A common issue with aluminum is "creep", where it gradually deforms under thermal stress. When aluminum heats up, it expands more than the steel bolts securing it, pushing the material out of the joint. As the system cools, the joint may loosen, increasing contact resistance and accelerating wear. Carefully selecting materials with compatible CTEs ensures long-term stability and reduces the risk of failure.

Protective Coatings and Surface Treatments

Applying surface treatments can significantly lower operating temperatures and reduce thermal stress. For example, coatings like black paint or epoxy powder increase emissivity to 0.9–0.95, which can lower temperatures by up to 40%. Sebastiaan de Boodt, Manager of Product Development at Rogers Corp, highlights this surprising benefit:

Although additional insulation might seem to raise temperature, enhanced radiation from coatings can lower it by 40%.

At connection points, silver plating stands out for its ability to minimize contact resistance, reducing localized hot spots that can exacerbate thermal expansion. Other treatments, like nickel plating and anodizing, protect the base metal from oxidation and wear, ensuring that thermal expansion cycles don’t degrade electrical connections over time. For optimal energy efficiency, busbar systems should be designed to limit temperature rises to 30°C (86°F) above ambient conditions. These surface treatments, combined with precise assembly practices, help maintain safe operating temperatures and system reliability.

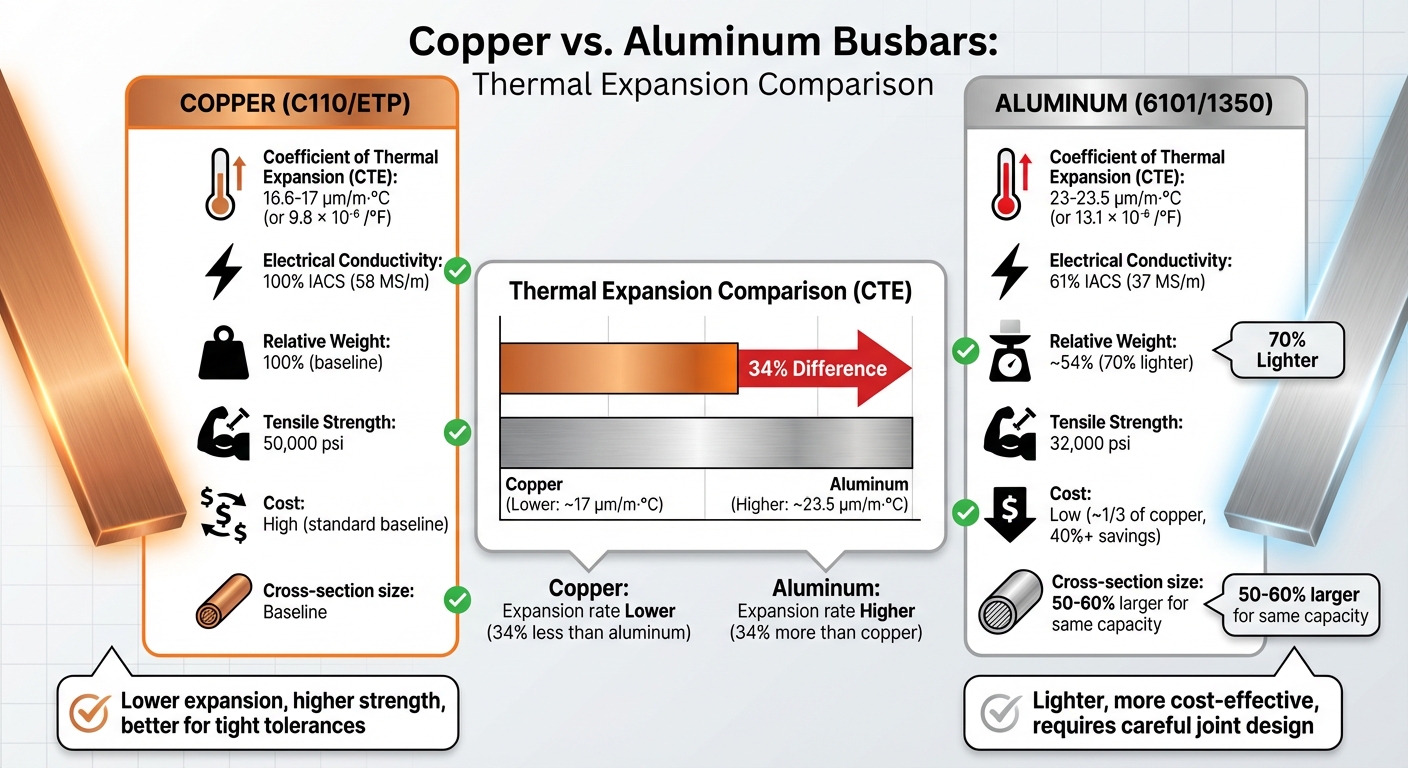

Copper vs. Aluminum Busbars: Thermal Expansion Comparison

Copper vs Aluminum Busbars: Thermal Expansion and Performance Comparison

Building on thermal management strategies, let’s dive into how copper and aluminum handle thermal stress. While earlier sections covered their coefficients of thermal expansion (CTE), here we’ll look at what those numbers mean in practice. Copper has a CTE of around 9.8 × 10⁻⁶ /°F, while aluminum’s is higher at 13.1 × 10⁻⁶ /°F. That’s about 34% more expansion for aluminum, which can strain connection points under heat. As AP Precision Metals explains:

Aluminum has a higher coefficient of thermal expansion compared to copper... This means aluminum expands more under heat, which can affect joint integrity in the long run if not correctly managed.

Beyond thermal behavior, other factors like cost and mechanical properties also influence the choice between these materials. Aluminum’s 70% weight advantage makes it appealing for structural applications. However, to match copper’s current-carrying capacity, aluminum busbars must have a cross-sectional area that’s 50–60% larger. This creates a trade-off: aluminum can reduce material costs - often by 40% or more in large-scale projects - but its higher expansion rate demands careful design, including specialized connectors and joint solutions.

On the other hand, copper’s tensile strength of 50,000 psi outperforms aluminum’s 32,000 psi. This makes copper more resistant to deformation during thermal cycling. Combined with its lower CTE, copper is often the go-to material for applications requiring tight tolerances and long-term stability in connections.

Material Comparison Table

Here’s a quick look at the key differences between copper and aluminum:

| Property | Copper (C110/ETP) | Aluminum (6101/1350) |

|---|---|---|

| CTE (μm/m·°C) | 16.6–17 | 23–23.5 |

| Conductivity (% IACS) | 100% | 61% |

| Tensile Strength (psi) | 50,000 | 32,000 |

| Relative Weight | 100% | ~54% |

| Cost Ratio | High (Standard) | Low (~1/3 of Copper) |

| Size Increase for Same Capacity | Baseline | 50–60% larger cross-section |

Conclusion

Thermal expansion plays a major role in busbar failures by putting stress on joints, which can stretch bolts, lower torque, and increase electrical resistance. As Allied Reliability explains:

Almost all bus failures are due to excessive heat.

Copper is often preferred over aluminum in busbar systems because of its lower thermal expansion coefficient (≈16.5 ppm/K) and strong mechanical properties. Aluminum, while lighter and more affordable, expands about 40% more than copper, requiring precise engineering to prevent joint failures.

To address thermal movement and minimize risks, engineers use strategies like flexible braided busbars, expansion joints, controlled torque bolting, and regular infrared inspections. Standards typically restrict a busbar's maximum temperature rise to about 65°C (150°F) to safeguard surrounding insulation. These practices help maintain stability and ensure consistent performance.

When properly designed and maintained, busbar systems can significantly reduce energy losses and maintenance costs, offering returns of 40–50%. With the right materials and ongoing thermal monitoring, they can operate reliably for over three decades.

FAQs

What impact does thermal expansion have on busbar systems?

Thermal expansion plays a crucial role in the reliability of busbars. When temperatures rise during operation, the metal conductor and its insulation expand at different rates. This uneven expansion can create mechanical stress, potentially leading to cracks in the insulation or even delamination. Such damage increases the likelihood of arcing, short circuits, and unexpected system shutdowns - serious risks for any electrical setup.

The problem doesn’t stop there. Repeated cycles of heating and cooling can loosen connections over time. This loosening boosts contact resistance, which, in turn, generates even more heat and speeds up wear and eventual failure. To counter these challenges, careful planning is key. Using the right materials, ensuring proper ventilation, and designing for a controlled temperature rise - typically no more than 30°F above ambient - can make a big difference.

Additionally, sourcing high-quality components from reliable suppliers like Electrical Trader can help ensure your busbar system is equipped to handle the stresses of thermal expansion without compromising performance.

Why is copper often chosen over aluminum for busbars, even though it costs more?

Copper is a popular choice for busbars due to its excellent electrical conductivity, higher ampacity, and strong mechanical durability when compared to aluminum. Another advantage is its lower thermal expansion coefficient, which helps ensure stability and minimizes the chances of mechanical issues developing over time.

Although copper comes with a higher initial cost, its ability to carry larger currents with reduced energy loss, combined with its long-lasting reliability, makes it a smart investment. This is particularly true in settings where performance and durability are essential.

How can you design busbars to handle thermal expansion effectively?

To manage thermal expansion in busbars effectively, start by selecting materials that can handle both electrical and thermal demands. Copper and copper alloys are excellent choices because they offer high conductivity while exhibiting relatively low thermal expansion. Pair these with high-temperature-rated insulation, such as PET or polymers designed to withstand up to 130°F, ensuring durability even in elevated temperature conditions. Industry standards often recommend limiting the temperature rise to 30°F above ambient to keep expansion in check.

On the mechanical side, it's essential to allow for movement. Incorporate flexible terminations like spring-loaded studs, sliding brackets, or expansion joints. These elements absorb axial growth while keeping electrical connections secure. Using mounting hardware with clearance gaps and low-profile designs can also improve airflow and act as a heat sink, further mitigating expansion risks.

To enhance reliability, consider surface finishes like tin, nickel, or silver plating. These coatings minimize contact resistance and prevent localized heating at connection points. By combining smart material selection, effective temperature control, and flexible mounting techniques, you can ensure your busbars handle thermal expansion without compromising their performance.