How Demand Response Reduces Peak Energy Costs

Share

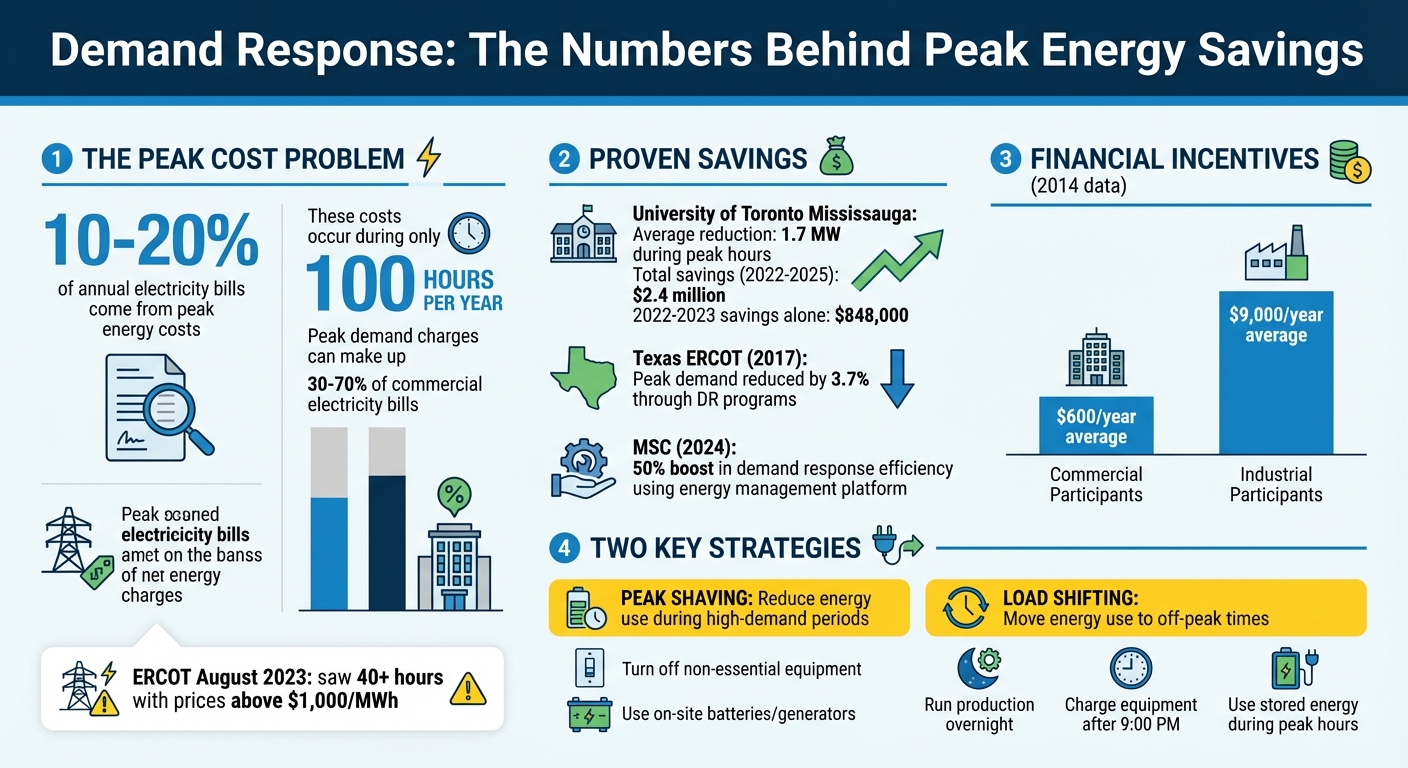

Peak energy costs can account for 10%-20% of annual electricity bills, even though they occur during only about 100 hours a year. Demand response (DR) programs help businesses lower these costs by reducing or shifting energy use during high-demand periods. Participants can save money, earn incentives, and support grid stability.

Key takeaways:

- Peak demand charges are based on your facility's highest energy use during short intervals and can exceed regular energy costs.

- Demand response programs offer financial rewards for reducing energy use during peak times.

- Strategies like peak shaving (reducing energy during peak hours) and load shifting (moving energy use to off-peak times) can significantly cut costs.

- Tools like Energy Management Software (EMS), smart meters, and battery storage systems simplify participation and optimize savings.

- In 2023, businesses in Texas avoided high electricity prices - over $1,000/MWh - by participating in DR programs.

Demand Response Programs: Cost Savings and Peak Energy Statistics

Webinar - Showcasing Peak Shaving & Load Flexibility Utilizing DER

Understanding Peak Energy Costs

Your electricity bill isn’t just about how much energy you use - it’s also about when you use it. Peak energy costs arise when the power grid is pushed close to its limits, forcing utilities to invest in additional infrastructure. This dynamic plays a major role in how peak demand charges influence overall electricity expenses.

What Are Peak Demand Charges?

Peak demand charges are fees tied to the highest amount of electricity your facility uses in a short time frame, typically measured over 15- or 30-minute intervals. Unlike regular energy charges, which are based on the total kilowatt-hours (kWh) you consume, demand charges reflect your facility's maximum strain on the utility’s system. These fees help utilities cover the cost of maintaining extra capacity to handle peak loads.

For many commercial and industrial operations, these charges can sometimes outpace the cost of the energy itself. For example, in August 2023, the ERCOT grid in Texas saw more than 40 hours where wholesale electricity prices soared above $1,000 per megawatt-hour (MWh). Managing energy use during these "coincident peaks" can significantly reduce your charges.

Factors That Drive Peak Costs

Several factors contribute to rising peak energy costs, and they go beyond just demand charges.

Weather is a major culprit. Scorching heat and humidity drive up air conditioning use, while freezing temperatures increase heating needs. These weather-driven spikes often coincide with daily surges in energy demand.

Grid capacity is another critical factor. The electrical grid must constantly balance supply and demand. During peak periods, when this balance is disrupted, utilities often rely on older, less efficient "peaker plants." These facilities cost far more to operate than base-load power plants. Unexpected outages or equipment failures can also strain the grid, forcing utilities to pay premium rates to stabilize the system.

"Reducing peak demand reduces the cost of electricity by reducing the need for additional generation capacity and avoiding the construction and maintenance costs associated with 'peakers' or standby energy plants."

– NJ Green Building Manual

The infrastructure needed to handle these short but intense demand spikes is incredibly expensive. Utilities invest heavily in generation and transmission systems that might only be used for about 100 hours a year. Yet, customers pay for this standby capacity all year long. Participating in demand response programs, which help reduce peak usage, can lead to noticeable savings on your energy bills.

How Demand Response Reduces Peak Energy Costs

Demand response strategies are a practical way to tackle the high costs associated with peak energy demand. By carefully managing when energy is used, businesses can significantly lower their electricity bills. Instead of paying premium rates during peak hours, companies can either reduce their energy consumption or shift energy-heavy activities to cheaper, off-peak times. This approach directly cuts down on demand charges, leading to smaller monthly bills.

Peak Shaving and Load Shifting

Peak shaving is all about reducing energy use when the grid is under stress. Businesses can achieve this in two ways: by turning off non-essential equipment (load shedding) or by using on-site resources like batteries or generators to meet energy needs without drawing from the grid. A great example comes from the University of Toronto Mississauga, which implemented peak shaving measures from 2022 to 2025. By tweaking temperature settings, lowering blinds, and reducing fan speeds during four-hour peak windows, they managed an average 1.7 MW reduction in peak energy use. These efforts saved them over $2.4 million in three years, including $848,000 in just the 2022-2023 period.

On the other hand, load shifting focuses on moving energy-intensive activities to times when electricity rates are lower. For instance, manufacturers might run production lines overnight, or businesses could charge electric vehicles and equipment after 9:00 PM. Some companies even rely on stored thermal or battery energy during the day to completely avoid high daytime rates. With demand charges often making up 30% to 70% of a commercial electricity bill, these strategies can lead to significant savings.

Automation has made both peak shaving and load shifting much easier to implement. Tools like Building Management Systems (BMS) and Energy Management Software (EMS) can receive real-time signals from utilities and automatically adjust energy usage. Some businesses are even using AI to predict peak demand and optimize the use of solar-plus-battery systems.

Utility Incentives and Rebates

In addition to cutting energy costs, businesses can earn money by participating in demand response programs. Utilities often offer two types of incentives: capacity payments, which reward businesses for being ready to reduce energy use when needed, and energy payments, which are based on the actual kilowatt-hours saved during a demand response event. For example, during August 2023 in Texas, wholesale energy prices in the ERCOT market soared above $1,000 per megawatt-hour for more than 40 hours. Businesses that reduced their energy use during this time avoided steep costs and earned incentive payments.

Many savvy companies "stack" their participation in multiple programs to maximize returns. This could mean enrolling in both grid-level (ISO/RTO) programs and utility-level programs. Payment structures vary by program type. Capacity programs usually offer moderate payments and require participation in just a few events per year, with 30 minutes to several days' notice. In contrast, ancillary services programs pay higher rates but require quicker responses - sometimes within seconds or minutes - and may trigger 10 to 30 times annually. In 2017, demand response programs in Texas helped reduce peak demand in the ERCOT region by about 3.7%, showcasing the power of collective action.

"Many grid operators and utilities are realizing that the most straightforward solution for addressing peak demand is reducing it."

– Enel North America

sbb-itb-501186b

Steps to Implement a Demand Response Program

Monitor and Analyze Energy Usage

Start by identifying your facility's peak energy consumption using Energy Management Software (EMS). These tools provide real-time insights into usage patterns and can automatically reduce nonessential systems during times of grid stress. Predictive analytics can also help forecast peak periods by analyzing historical trends, weather data, and grid conditions. Installing IoT sensors throughout your facility adds another layer of detail, pinpointing which systems or equipment contribute most to your energy load.

Take MSC as an example. In late 2024, they adopted Sanalife's E360 Energy Management Platform to automate energy control and track usage. This move led to a 50% boost in demand response efficiency within the PJM territory, effectively doubling their ability to reduce energy demand during critical periods.

To stay ahead, set peak alerts 24 hours in advance. Erin Schmerschneider, Director of Energy Advisory at Pilot Energy, highlights this approach:

"We send peak alerts, notifying clients of potential peak-setting hours a day in advance and giving them a two-hour window to curtail anything they can to reduce demand".

Use interactive dashboards to monitor your progress toward peak reduction goals. Another useful strategy is staggering the start times of energy-intensive equipment to prevent localized spikes in usage.

Invest in Load Management Equipment

Once you've identified peak usage patterns, the next step is equipping your facility to manage loads effectively. This often means investing in hardware that simplifies demand response and makes it financially worthwhile. For example, Load Control Receivers (LCRs) can cycle or interrupt large loads like HVAC systems, water heaters, or industrial machinery. These devices range from small 2-amp units to larger models with 30-amp relays capable of handling multiple systems. Smart thermostats are another valuable addition, as they adjust temperatures automatically during peak events.

For businesses serious about reducing peak demand, energy storage systems are a game-changer. These systems allow you to store electricity during off-peak hours and use it when demand - and costs - are at their highest. Standby generators can also play a role, taking over critical loads when the grid is under stress. While manual curtailment works for programs with longer response times, automation is essential for high-speed ancillary services that require action within seconds or minutes.

To build an effective load management system, reliable electrical equipment is a must. Platforms like Electrical Trader offer a wide range of power distribution tools, including breakers, transformers, and generators, ensuring you have the infrastructure to support your strategy.

Participate in Utility Demand Response Programs

With monitoring systems and load management equipment in place, the final step is to participate in demand response (DR) programs offered by local utilities. Businesses can join these programs either directly through their utility or by bidding their capabilities into wholesale markets managed by Independent System Operators (ISOs) or Regional Transmission Organizations (RTOs). Here's a compelling stat: In 2014, commercial participants in demand response programs earned an average of nearly $600 annually, while industrial participants received over $9,000.

To get started, identify available programs in your area. Tools like the FEMP Utility Program Navigator can help you search for demand response and Time-Variable Pricing programs by state and utility. For instance, as of January 2026, Alabama Power offers options like Real-Time Pricing Plans and Non-Firm Capacity Interruptible Credit Options. Similarly, AEP Texas provides a specific Load Management Program tailored for commercial clients.

When choosing a program, consider your facility's operational flexibility. Time-of-Use (TOU) rates work well for businesses with predictable schedules, while Real-Time Pricing (RTP) suits those that can quickly adjust loads based on price signals. Many businesses increase returns by "stacking" participation in multiple programs - combining grid-level capacity offerings with local utility incentives. Look for utility programs like "Curtailable Service" or "Interruptible Credits", which often offer higher payouts for committed load reductions. Automated control systems can streamline participation, ensuring consistent performance without requiring manual intervention during events.

The Role of Equipment in Demand Response

Equipment Needed for Load Management

The hardware you select plays a key role in how well you can manage and reduce peak energy costs. For instance, Load Control Receivers (LCRs) are essential for controlling energy usage. These range from 2-amp units for smaller loads to 30-amp relays designed for industrial applications, offering flexibility to suit different needs. To further optimize energy use, Battery Energy Storage Systems (BESS) are highly effective. They help shift loads and manage peak demand, which can significantly lower demand charges - these charges often represent 30% to 70% of a commercial or industrial customer's total energy bill.

On-site power generation solutions like generators, solar arrays, and wind turbines are also valuable. They provide energy during peak periods, reducing dependency on the grid. Meanwhile, Advanced Metering Infrastructure (AMI), including smart meters and IoT sensors, gathers real-time consumption data, ensuring accurate utility verification. Reliable communication methods - such as RF Mesh, Cellular, ZigBee, or PLC - are crucial for transmitting signals between your facility and the utility.

When sourcing these components, platforms like Electrical Trader simplify the process. They offer a wide selection of breakers, transformers, energy storage systems, and power generation equipment, both new and used, making it easier to meet your specific demand response requirements. A well-planned equipment setup lays the groundwork for choosing trustworthy suppliers who can support consistent performance.

Choosing Reliable Suppliers

Once you've identified the right equipment for load management, selecting dependable suppliers becomes equally important. High-quality equipment is essential to ensure consistent and efficient load reductions during demand response events. Automated control systems, for example, can remove the need for manual intervention, but their effectiveness depends entirely on the reliability of the hardware they rely on. Compatibility is another key factor - solutions that are forward and backward compatible allow you to integrate new technology with existing systems without requiring a full replacement.

Safety and compliance are critical, especially when cycling high-load equipment like industrial machines or HVAC systems. Trusted suppliers offer components that meet industry standards and work seamlessly with third-party assets, such as Honeywell or Ecobee thermostats. Experienced vendors with proven expertise in power distribution equipment are better positioned to deliver reliable solutions.

"In 2017, Liberty Property Trust demonstrated this principle by implementing smart grid technology and metering across its building portfolio, successfully executing load shedding during demand response events without negatively affecting tenant comfort or operations." – Liberty Property Trust case study

When evaluating suppliers, focus on those whose equipment aligns with your local utility's communication protocols and meets your facility's specific functional needs. Whether you're implementing a standard Load Management System (LMS) or a more advanced Distributed Energy Resource Management System (DERMS), partnering with the right supplier strengthens your demand response framework and helps you effectively cut peak energy costs.

Conclusion

Demand response programs offer a practical way to cut peak energy costs while improving grid reliability. By reducing energy consumption during high-demand periods, businesses can sidestep hefty demand charges and help avoid the use of expensive peaker plants, which often drive up wholesale electricity prices.

For industrial facilities, participating in these programs can lead to impressive financial returns. Many businesses earn notable annual incentives while playing a role in reducing nationwide peak energy demand.

To fully benefit, it’s essential to monitor energy usage closely and invest in tools like Load Control Receivers, Battery Energy Storage Systems, and Advanced Metering Infrastructure. These technologies make it easier to automate load shifts and minimize reliance on the grid. Platforms such as Electrical Trader simplify the process of sourcing these components, offering a range of new and used breakers, transformers, and power generation equipment tailored to specific needs. These investments not only help secure utility program incentives but also pave the way for sustained savings.

Utility demand response programs also provide additional perks like capacity payments, bill credits, and direct financial incentives. As Eaton highlights:

"Demand-response resources replace higher cost, less efficient and more carbon-intensive generation".

Over time, the advantages extend beyond immediate savings. Businesses benefit from lower infrastructure costs, decreased wholesale energy prices, and reduced strain on transmission systems. By combining smart equipment investments with active participation in these programs, businesses can achieve ongoing cost reductions while supporting a more resilient and efficient energy grid. This approach delivers both short-term savings and long-term improvements in energy management.

FAQs

What steps can businesses take to implement demand response strategies effectively?

To put demand response (DR) strategies into action, the first step for businesses is to conduct an energy audit. This helps identify equipment or processes - like HVAC systems or industrial machinery - that can be adjusted during peak demand times. The goal is to find areas where energy use can be reduced or shifted without interrupting day-to-day operations.

Once you’ve pinpointed these opportunities, choose a DR program that fits your business needs. Options might include time-of-use rates or direct load control programs. To make energy adjustments easier, consider installing smart technology, such as advanced meters or automated control systems. It’s also important to establish clear procedures for handling DR events and train your team to respond quickly and safely when notifications come through. After each event, review your performance to measure savings and fine-tune your approach for even better results.

By taking these steps, businesses can cut energy costs during peak times, benefit from utility incentives, and support a more reliable power grid.

What financial benefits can I get from joining a demand response program?

By joining a demand response program, you can earn bill credits, rebates, rate discounts, or even direct payments simply by cutting back on your energy use during peak demand periods. For many residential customers, this could mean annual rewards averaging around $40, though the exact amount depends on the specific program and your energy consumption.

These programs don’t just save you money - they also play a role in creating a more stable and efficient power grid by easing the strain during times of high demand.

What’s the difference between peak shaving and load shifting in managing energy costs?

Peak shaving and load shifting are two effective strategies for managing energy expenses, though they tackle the challenge in different ways.

Peak shaving is all about cutting back on electricity use during the most expensive times of the day. Think of those sweltering summer afternoons when air conditioners are running at full blast, and energy demand soars. By reducing energy usage during these high-demand periods, businesses can lower their peak demand charges, which are typically billed in dollars per kilowatt ($/kW).

Load shifting, however, takes a different approach. Instead of reducing energy use, it shifts it to off-peak hours when electricity rates are cheaper - usually overnight. The goal here isn’t to use less energy overall but to spread out consumption more evenly throughout the day. This helps avoid the higher costs that come with peak pricing.

Put simply, peak shaving trims down the energy spikes, while load shifting smooths out the overall usage pattern.