Ultimate Guide to Electrical Equipment Maintenance

Share

Maintaining electrical equipment is critical to avoiding failures, reducing risks, and ensuring safety. Here's what you need to know:

- Why It Matters: Regular maintenance prevents costly downtime, protects workers, and ensures compliance with standards like NFPA 70B (mandatory since December 2025) and NFPA 70E.

- Key Strategies: Use preventive, predictive, and reliability-centered maintenance to keep equipment running efficiently. Tools like infrared thermography and insulation resistance testing help identify issues early.

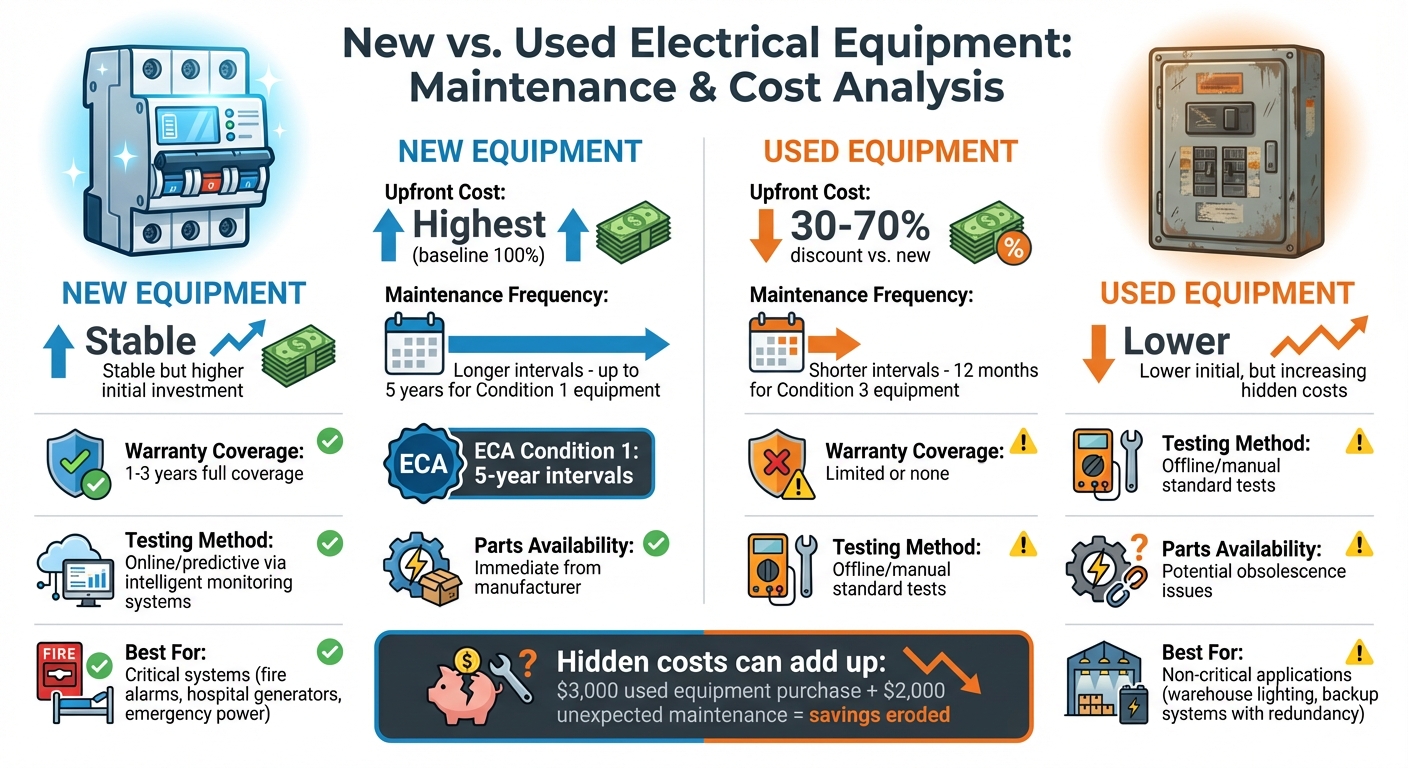

- New vs. Used Equipment: New equipment comes with warranties and longer maintenance intervals. Used equipment is cheaper upfront but needs more frequent servicing.

- Documentation & Scheduling: A well-documented maintenance plan, supported by tools like CMMS, ensures compliance and smooth operations.

Bottom Line: A structured maintenance program saves money, improves reliability, and ensures safety. Keep reading for actionable steps and insights.

Navigating NFPA 70B - Electrical Maintenance

Core Maintenance Strategies for Reliable Operations

Implementing effective maintenance strategies is key to keeping equipment reliable and safe, aligning with the U.S. standards outlined earlier.

Preventive, Predictive, and Reliability-Centered Maintenance

Preventive maintenance works on a fixed schedule, often guided by manufacturer recommendations or historical data. This approach helps prevent about 66.7% of system failures. For example, electrical equipment like transformers might be checked every three years. However, sticking strictly to a set schedule can sometimes lead to maintenance being done either too soon or too late.

Predictive maintenance takes things up a notch by using IoT sensors to monitor equipment in real time. These sensors track factors like vibration, temperature, and acoustics, triggering maintenance only when necessary. This method not only cuts downtime by 5–15% but can also increase productivity by 5–20%.

"Predictive maintenance builds on condition-based monitoring to optimize the performance and lifespan of equipment by continually assessing its health in real time."

– IBM

Reliability-centered maintenance (RCM) is a more strategic approach. It tailors maintenance methods - be it preventive, predictive, or reactive - based on an asset's importance, the cost of failure, and safety risks. For example, a hospital’s emergency generator demands more frequent checks compared to a warehouse lighting panel. This strategy ensures maintenance tasks are focused on maintaining operational reliability.

High-Impact Maintenance Tasks

Some maintenance tasks deliver a significant impact on equipment health and performance.

- Infrared thermography: Conducted while equipment is energized, this technique identifies hotspots caused by loose connections, overloaded circuits, or worn components before they fail.

- Insulation resistance testing: This test detects cable, motor, and transformer insulation issues, helping to avoid short circuits.

- Vibration analysis: Used on rotating machinery like motors and pumps, this method pinpoints imbalances, misalignment, or worn bearings.

Simple tasks like regular cleaning and tightening also play an important role. For instance, vacuuming enclosures instead of using compressed air prevents debris buildup, while tightening bolted connections reduces the risk of hotspots that infrared scans might detect. Routine testing of overcurrent protection devices, such as circuit breakers and relays, ensures they function properly, safeguarding both equipment and personnel.

| Maintenance Task | Primary Equipment | Key Benefits |

|---|---|---|

| Infrared Thermography | Electrical panels, switchgear | Identifies overheating and loose connections |

| Insulation Resistance Testing | Cables, motors, transformers | Detects insulation breakdown before failures |

| Vibration Analysis | Motors, pumps, rotating machinery | Diagnoses imbalance, misalignment, and wear |

| Connection Tightening | Switchgear, breakers, terminals | Prevents hotspots and reduces resistance |

| Power Quality Analysis | Distribution systems | Highlights harmonics, voltage sags, and energy waste |

Scheduling and Documentation Practices

A solid maintenance plan relies on systematic scheduling and detailed documentation. Maintenance intervals are often guided by an Equipment Condition Assessment (ECA), which reviews an asset’s physical state, its operational importance, and its working environment. For instance, NFPA 70B mandates such assessments. While most electrical equipment is inspected annually, some components may follow a three-year cycle depending on their condition and environment.

Proper documentation is equally critical. Record asset IDs, test results, photos of deficiencies, and corrective actions. A Computerized Maintenance Management System (CMMS) can simplify this process by automating records, generating work orders for detected issues, and ensuring compliance with regulations. Once set up, these systems streamline maintenance tasks and keep everything organized.

"The failure rate of electrical equipment is three times higher for components that are not part of a scheduled preventive maintenance program as compared with those that are."

– The Hanover Insurance Group

New vs. Used Equipment Maintenance: Key Considerations

New vs Used Electrical Equipment: Maintenance Requirements and Cost Comparison

Factors That Influence Maintenance Needs

The maintenance requirements for equipment are heavily influenced by its age and history. New equipment typically adheres to manufacturer-recommended maintenance schedules to ensure warranties remain valid. On the other hand, used equipment often requires an Equipment Condition Assessment (ECA) to evaluate its physical condition, operating environment, and importance within a system. For example, guidelines like NFPA 70B recommend inspection intervals based on condition: poorly maintained equipment (Condition 3) needs checks every 12 months, while well-maintained assets (Condition 1) may only require inspections every five years.

Used equipment often faces issues like loose connections, corrosion, and insulation wear as it ages. For instance, while a transformer’s core components might remain functional, its accessories could require replacement or more frequent attention to maintain reliability. In contrast, modern equipment equipped with intelligent monitoring systems demands less frequent manual testing than older models.

"Many issues that affect quality and performance can be traced back to poor, or a total lack of, routine maintenance."

– David Colombo, P.E., Owner and Principal, Power Engineers, LLC

These assessments and classifications directly influence both the cost and risk factors associated with maintenance, as discussed next.

Cost and Risk Considerations

The financial and operational risks tied to maintenance vary significantly between new and used equipment. While used equipment can save buyers 30%–70% upfront compared to new units, these savings often come with trade-offs. New equipment typically includes 1–3 year warranties and lower maintenance demands, whereas used equipment requires more frequent servicing and poses a higher risk of unplanned repairs.

Over time, the true cost difference becomes clear. Even minor issues, like a meter failure, can lead to repair costs that far exceed the price of the part itself - labor and overhead can drive the total bill to around $500.

"The price of the part itself is often inconsequential compared with the labor to resolve the problem."

– Gay Gordon-Byrne, Vice President of Technology & Development, TekTrakker Information Systems, LLC

| Feature | New Equipment | Used Equipment |

|---|---|---|

| Upfront Cost | Highest | 30–70% discount |

| Maintenance Frequency | Longer intervals (up to 5 years for Condition 1) | Shorter intervals (12 months for Condition 3) |

| Warranty Coverage | 1–3 years full coverage | Limited or none |

| Testing Method | Online/predictive via intelligent systems | Offline/manual standard tests |

| Parts Availability | Immediate from manufacturer | Potential obsolescence issues |

Use Cases for New vs. Used Equipment

Matching maintenance strategies with the application’s importance is critical. For systems where failure is not an option - like fire alarms or hospital generators - new equipment with rigorous preventive maintenance is essential. These critical systems demand reliability and cannot afford downtime.

For less critical applications, used equipment can be a practical and budget-friendly choice. For example, warehouse lighting panels or backup systems with built-in redundancy can handle the more frequent maintenance needs of used equipment. When opting for used equipment, it’s important to request detailed maintenance records, recent test results, and compliance certificates to avoid delays during installation. Online platforms like Electrical Trader (https://electricaltrader.com) provide access to both new and used components, helping professionals balance reliability with budget constraints.

However, as Justin Noland of Kubota cautions, hidden maintenance costs can quickly diminish the initial savings of used equipment:

"You buy a used piece of equipment for $3,000. The next season, you're spending $2,000 (on maintenance) that you weren't necessarily anticipating or budgeting for."

To make an informed decision, it’s crucial to calculate the total cost of ownership. This includes factoring in ongoing maintenance, the availability of replacement parts, and potential downtime when choosing between new and used equipment.

sbb-itb-501186b

Planning a Maintenance Program

Building an Asset Inventory and Criticality Ranking

The first step in creating a maintenance program is to take stock of all your electrical equipment and rank its importance. According to NFPA 70B-2023, an Electrical Maintenance Plan (EMP) must include a detailed equipment survey, clearly defined roles, and a policy for keeping records. Start by listing every piece of electrical distribution equipment in your facility, organizing it by voltage class and type, such as transformers, circuit breakers, and switchgear. Then, evaluate each asset based on its physical condition, criticality, and operating environment to set appropriate maintenance intervals.

"The equipment condition assessment (ECA) is driven by the HIGHEST value of these three conditions [Physical condition, Criticality, Operating environment]" – Scott Brady, PE, Region Manager of Technical Application Support, Eaton

This means that even if a transformer is in excellent physical shape, if it’s highly critical (Condition 3), it will still require annual inspections under the Condition 3 maintenance schedule. On the other hand, equipment rated at Condition 1 may only need maintenance every five years. By ranking criticality, you can prioritize resources for systems where failures would pose safety risks or disrupt operations - think hospital generators, emergency power systems, or motors essential to production. This inventory becomes the foundation for weaving safety into your maintenance strategy.

Integrating Safety and Standards into Maintenance

Safety must be at the core of your maintenance program. Your EMP should align with NFPA 70E standards, which include arc flash labeling, lockout/tagout procedures, and proper storage for personal protective equipment (PPE).

"Team members developing the EMP must understand each equipment's role and environmental impact" – Ryan Roth, Global Product Manager, ABB Electrification Service

Each maintenance interval should have a clearly defined scope of work, outlining safety precautions, required shutdown times, and personnel training. Keep all system documentation up to date - this includes one-line diagrams, short-circuit studies, coordination analyses, and arc flash calculations. Use the results from initial commissioning tests (ANSI/NETA ATS) as a benchmark for future maintenance assessments (ANSI/NETA MTS). Comparing current data to this baseline helps identify wear and tear before it becomes a hazard.

Using Metrics to Optimize Maintenance

Once your inventory and safety protocols are in place, focus on metrics to fine-tune your maintenance efforts. The goal is to reduce Total Cost of Ownership (TCO) while keeping equipment running smoothly. Track test results to spot trends that may signal the need for replacements or changes to servicing schedules. Preventive maintenance is key - unmaintained equipment fails at three times the rate of assets in a scheduled program.

Regularly monitor voltage, current, temperature, insulation, and grounding to catch early signs of trouble. For transformers, conduct annual Dissolved-Gas-in-Oil (DGA) tests and monitor factors like dielectric breakdown, acidity, and power factor. Grounding systems for liquid-filled transformers should maintain a resistance of 25 ohms or less. Advanced sensors and intelligent trip units now provide real-time health data and high-speed event logs, which can reduce the need for some manual inspections.

"Data is the basis for any appropriate maintenance plan and a continuous feedback loop must be employed to improve the plan" – Ryan Roth, Global Product Manager, ABB Electrification Service

Audit your EMP at least every five years to ensure it stays effective and meets regulatory standards. A Computerized Maintenance Management System (CMMS) can simplify this process by automating the logging of inspections, infrared scans, and test results. This creates a reliable audit trail for compliance and helps prevent failures while improving reliability and cutting emergency repair costs.

Conclusion: Key Takeaways for Reliable Equipment Maintenance

Core Maintenance Practices

The NFPA 70B now requires regular maintenance of electrical equipment. By sticking to a consistent maintenance routine, you can prevent most electrical system failures and safeguard vital assets. A solid program blends time-based schedules, condition-based testing, and predictive monitoring powered by tools like sensors and AI. Since insulation breakdown is a leading cause of equipment failure, it's crucial to establish baseline readings, monitor trends, and prioritize assets based on their physical condition, operational importance, and environmental factors. These steps lay the groundwork for maintaining system reliability with the right tools and strategies.

Tools and Resources for Maintenance Success

An effective maintenance program hinges on the right mix of diagnostic tools, documentation systems, and dependable replacement parts. Tools like infrared cameras, megger tests, and ground resistance measurements help catch faults early. A Computerized Maintenance Management System (CMMS) can streamline documentation, creating an audit trail that aligns with OSHA and NFPA 70B standards. When replacing worn-out components or sourcing parts for repairs, reliable suppliers are essential. For instance, Electrical Trader (https://electricaltrader.com) provides a one-stop marketplace for both new and used electrical components, including circuit breakers, transformers, high-voltage switchgear, and power generation equipment. This ensures quick access to competitively priced parts. With these tools and systems in place, your maintenance strategy can adapt and thrive, supporting long-term reliability.

Final Thoughts on Long-Term Reliability

By combining proven methods with the right tools, a proactive maintenance strategy can significantly reduce downtime and risk.

"A well-administered testing program can prevent accidents, save lives, minimize costly breakdowns and reduce unplanned outages." – Eric Nation, General Manager, High Voltage Maintenance

The move toward mandatory maintenance standards highlights an industry reality: electrical failures often develop gradually and unnoticed until they escalate into emergencies. Incorporating regular infrared scans to identify hotspots and continuous monitoring to detect potential problems early is essential. Additionally, over half of machinery failures are tied to preventable issues like component misalignment. This guide has emphasized that a balanced approach - integrating time-based schedules, condition-based testing, and predictive monitoring - ensures consistent operational reliability. By keeping detailed inspection records, training your team on safety protocols, and leveraging data for informed decisions, you can lower the total cost of ownership while keeping your systems safe and dependable for the long haul.

FAQs

What’s the difference between preventive, predictive, and reliability-centered maintenance for electrical equipment?

Preventive, predictive, and reliability-centered maintenance are three distinct strategies aimed at keeping electrical equipment running smoothly. Each method approaches maintenance differently, based on timing and the tools used.

- Preventive maintenance focuses on performing regular tasks - like inspections, lubrication, or tightening - on a set schedule. The idea here is to address potential issues before they arise, operating on the assumption that equipment degrades in a predictable way over time.

- Predictive maintenance takes a more advanced approach by using sensors and data analytics to monitor equipment in real time. Maintenance is carried out only when the data signals that a problem is likely, which helps avoid unnecessary repairs and minimizes downtime.

- Reliability-centered maintenance (RCM) takes things a step further by analyzing each piece of equipment individually. It determines the best combination of strategies - whether preventive, predictive, or corrective - based on how critical the equipment is and the impact of potential failures.

To put it simply, preventive maintenance follows a fixed schedule, predictive maintenance reacts to the equipment’s actual condition, and RCM blends different methods to balance reliability and cost efficiency.

What are the key maintenance differences between new and used electrical equipment?

New electrical equipment requires careful maintenance, starting with following the manufacturer’s guidelines. This includes checking that all connections are secure, insulation remains dry, and protective coatings are intact. It’s also essential to perform initial calibration or functional testing to ensure the equipment operates as designed. Since there’s no prior service history, early maintenance focuses on resolving installation-related issues like loose terminals or grounding errors.

Used equipment, however, comes with a different set of challenges. Without a clear record of wear and usage, condition-based inspections and frequent testing become necessary. Technicians look for signs of moisture, dust buildup, worn parts, or previous repairs that might lead to overheating or insulation problems. Regular procedures like infrared scans and insulation resistance tests are key to extending the equipment’s service life and avoiding unexpected failures.

No matter if your equipment is brand-new or previously owned, Electrical Trader provides a broad range of components, along with the documentation and warranty details you need to establish a solid maintenance plan from the start.

What tools and technologies are necessary for maintaining electrical equipment effectively?

Maintaining electrical equipment properly calls for a mix of basic tools and cutting-edge diagnostic technologies. Essentials like insulated screwdrivers, pliers, wrenches, and voltage testers are indispensable for everyday tasks such as tightening connections or conducting visual checks. Alongside these, safety gear - like insulated gloves and safety glasses - is a must to protect technicians during hands-on work.

Modern tools take maintenance to the next level, improving both accuracy and efficiency. Devices such as digital multimeters, clamp meters, insulation testers, and infrared cameras enable technicians to measure voltage, current, and thermal conditions without interrupting operations. For more complex diagnostics, tools like circuit breaker analyzers and relay test sets provide in-depth insights. When paired with asset management software, these tools support condition-based maintenance by tracking performance trends and scheduling inspections before issues arise.

If you're looking to outfit your maintenance program with the right tools and spare parts, platforms like Electrical Trader offer a wide selection - from basic hand tools to advanced diagnostic equipment - all available in one convenient marketplace.