Fuse or Circuit Breaker: Best Use Cases

Share

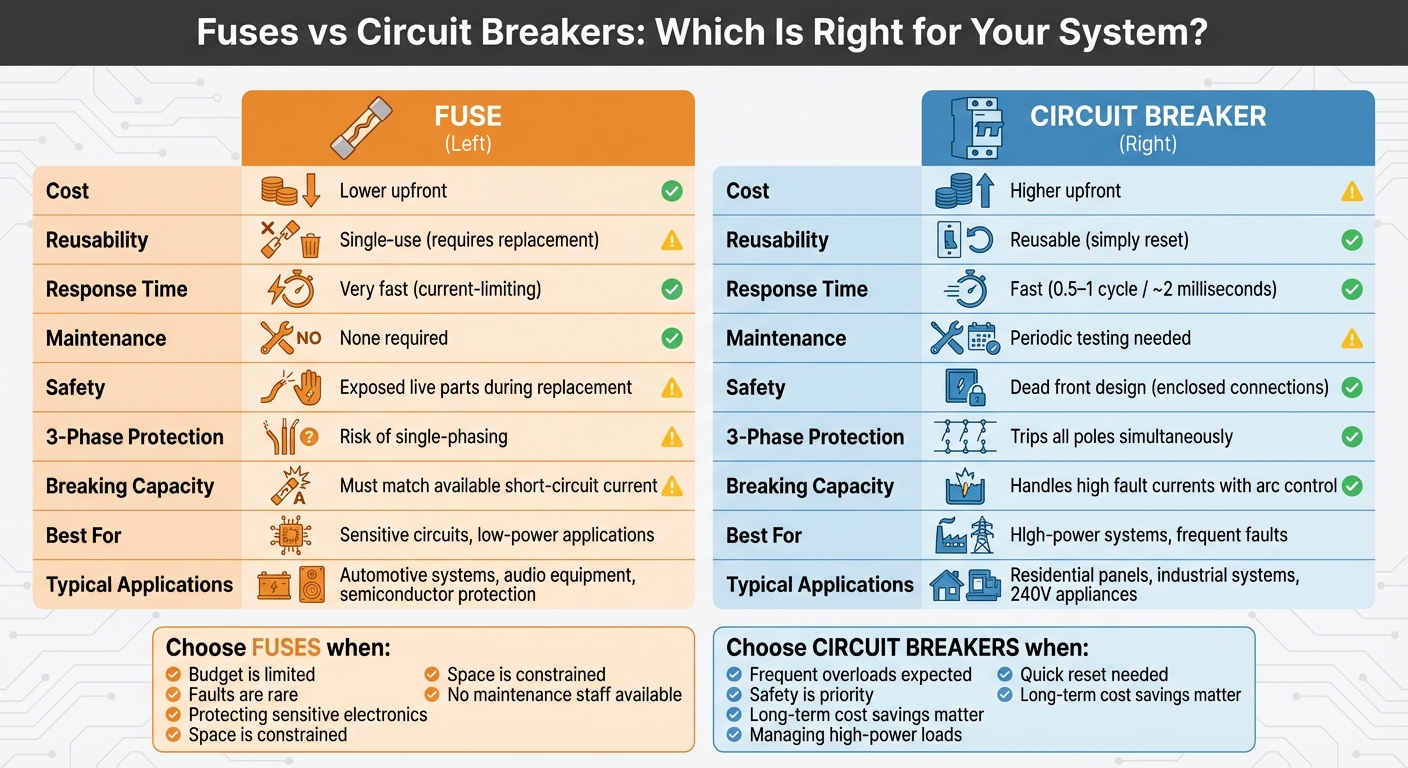

When deciding between fuses and circuit breakers, your choice depends on the specific needs of your system. Fuses are simple, cost-effective, and react quickly to protect sensitive circuits. However, they are single-use and require manual replacement after each fault. Circuit breakers, on the other hand, are reusable, easier to reset, and ideal for environments with frequent faults or higher power demands, though they come with a higher initial cost.

Key Points:

- Fuses: Quick response, lower upfront cost, single-use, ideal for sensitive circuits.

- Circuit Breakers: Reusable, safer operation, higher initial cost, better for frequent faults.

Quick Comparison:

| Feature | Fuse | Circuit Breaker |

|---|---|---|

| Cost | Lower upfront | Higher upfront |

| Reusability | Single-use | Reusable |

| Response Time | Faster (current-limiting) | Fast (0.5–1 cycle) |

| Maintenance | None required | Periodic testing needed |

| Safety | Exposed live parts | Enclosed connections |

| Best For | Sensitive circuits | High-power systems |

Fuses work well for low-power, sensitive applications, while circuit breakers excel in high-power, frequently tripping environments. Choose based on your system's power needs, maintenance preferences, and safety requirements.

Fuses vs Circuit Breakers: Complete Feature Comparison Chart

1. Fuse

Response Time

Fuses act quickly to protect circuits by melting their metal filament when excess current is detected. This immediate response is crucial for limiting fault currents and safeguarding downstream components during short circuits. For instance, fast-acting fuses are designed to react instantly, while time-delay (or slow-blow) fuses can handle temporary inrush currents - like those from motor startups - without causing unnecessary interruptions.

Dual-element fuses take this a step further by combining two elements in series. One responds slowly to low-magnitude overloads, while the other reacts instantly to high-magnitude short circuits. However, ambient temperature can significantly affect their performance. For example, at 140°F (60°C), a typical dual-element fuse may open at around 87% of its rated current.

Breaking Capacity

The interrupting rating, also known as breaking capacity, measures the maximum fault current a fuse can safely stop without failing catastrophically. This rating must be at least equal to the available short-circuit current in the circuit. As outlined in technical documentation:

"The interrupting rating of a fuse must be equal to or greater than the available short circuit current of the circuit to provide its intended protection".

Fuses are particularly effective at protecting semiconductor devices, like solid-state relays, because they limit the heat generated (I²T) during a fault more efficiently than many mechanical breakers. Under UL 248 standards, fuses are tested to open at 135% of their rated current, whereas IEC 60127 fuses are tested at 150%. To maintain safety, panels should always be labeled with the specific fuse type required, ensuring users don’t install incorrect replacements.

Cost Effectiveness

The cost of using fuses goes beyond their purchase price. For example, the total assembly - including the fuse holder - ranges from $32.89 to $49.98, which is notably higher than the approximate $23.21 price of a comparable miniature circuit breaker. However, the real expense comes during operation. A blown fuse requires identifying the fault, de-energizing the system, and manually replacing the fuse - tasks that can take about 2 hours of maintenance time. With electricians charging an average of $100 per hour, this adds up quickly.

Over two decades, a system with 12 fuses blowing just twice a year could rack up at least $4,800 in labor and downtime costs, not counting the cost of replacement parts. Brian S. Elliott, Chief of Engineering at Air Options, Inc., sums it up well:

"The recurring argument... in favor of circuit breakers is that they are easier to reset... the usual argument in favor of fuses is that they are dirt cheap".

In environments with rare overcurrent events, fuses can be a cost-effective solution due to their simplicity. But in high-fault scenarios, the repeated replacement costs can quickly add up.

Reusability

Fuses are single-use by design, ensuring definitive fault clearance but requiring replacement after every event. This makes them ideal for critical applications where absolute reliability is essential. However, in facilities with frequent overcurrent events, this can pose operational challenges. For applications like motors or transformers with high startup surges, time-delay fuses are a practical choice to reduce unnecessary replacements caused by harmless inrush currents.

Next, we’ll look at how circuit breakers handle similar protection needs.

2. Circuit Breaker

Reusability

Circuit breakers use either a bimetallic strip or an electromagnet to trip during overcurrent events. Once the issue is resolved, you can simply reset the breaker to restore power - no replacement parts required.

This resettable design eliminates the hassle of keeping spare components on hand. Plus, built-in trip indicators make it easy to identify which breaker has tripped. Many breakers are even designed to double as manual on-off switches, reducing the need for separate disconnect devices. While the upfront cost of a circuit breaker is higher than a fuse, the lack of recurring replacement costs and labor often makes them more economical in the long run.

Response Time

Magnetic circuit breakers respond incredibly fast - within about 2 milliseconds. For overload situations, thermal breakers are designed to handle temporary surges. For example, they can tolerate a 2× overload for 8 to 40 seconds but will trip within 1 to 2 seconds if exposed to a 10× overload.

This combination of thermal and magnetic mechanisms makes circuit breakers a strong choice for industrial and commercial systems where maintaining uptime is critical. John Yoon, PE, Lead Electrical Engineer at McGuire Engineers, highlights their versatility:

"A circuit breaker can be open and closed against all magnitudes of current, up to its short circuit rating, basically acting as a switching device".

Breaking Capacity

Breaking capacity, also known as interrupting rating, refers to the maximum fault current a breaker can safely interrupt. In high-power or industrial settings, the breaker's durable frame is built to handle the physical stress caused by high fault currents. A key feature of a breaker's performance is its ability to control and extinguish the electrical arc that forms during a fault.

In complex industrial distribution systems, breakers equipped with electronic trip units allow engineers to fine-tune the time-current curve. This ensures that the breaker nearest to the fault trips first, preventing a complete facility shutdown. Achieving this level of selective coordination is harder with standard thermal-magnetic breakers, which have a wider trip band and a "dog-leg" characteristic in the instantaneous region.

Cost Effectiveness

Although circuit breakers have a higher initial cost, they offer significant long-term savings by eliminating the need for replacements - especially in environments prone to frequent overcurrent events. Additionally, circuit breaker disconnects are about half the size of their fused counterparts, making them easier to fit into crowded utility panels. For continuous loads lasting three hours or more, standard breakers must be derated to 80% of their rated ampacity unless specifically designed for 100% duty.

These features and factors lay the groundwork for a detailed comparison of the advantages and disadvantages of circuit breakers and fuses.

Fuse vs. Circuit Breaker: Which One Should I Use?

sbb-itb-501186b

Pros and Cons

To make an informed choice between fuses and circuit breakers, it's essential to weigh their strengths and weaknesses. Each option has distinct advantages and limitations, making them suitable for different scenarios.

Fuses are appealing for their low upfront cost and maintenance-free nature, thanks to their lack of moving parts. Their simple design ensures dependable performance over time. However, they can suffer from degradation due to heat cycling and vibration, occasionally leading to nuisance trips. The biggest downside? Fuses are single-use. Once they blow, they need to be replaced, which means keeping spares on hand. Additionally, larger fuses often have exposed live parts, which can pose safety risks during replacement.

Circuit breakers, while more expensive initially, offer convenience by being resettable. Their "dead front" design keeps live connections safely enclosed, significantly reducing the risk of electrocution and preventing unsafe bypassing practices. Brian S. Elliott, Chief of Engineering at Air Options, Inc., highlights their practicality:

"The recurring argument that I have heard in favor of circuit breakers is that they are easier to reset after a failure situation has occurred".

That said, circuit breakers do require periodic maintenance to keep their mechanical components in good working condition. Frequent tripping can also lead to wear and tear over time.

Here’s a quick side-by-side comparison of their key differences:

| Feature | Fuse | Circuit Breaker |

|---|---|---|

| Initial Cost | Low | High |

| Reusability | Single-use | Reusable |

| Response Time | Very fast (current-limiting) | Fast (0.5–1 cycle) |

| Maintenance | None | Periodic testing needed |

| Safety | Exposed live parts | Dead front design |

| 3-Phase Protection | Risk of single-phasing | Trips all poles simultaneously |

Temperature sensitivity is another factor to consider. Both fuses and circuit breakers are affected by ambient heat, but magnetic-hydraulic breakers stand out for their resistance to temperature fluctuations.

One notable safety advantage of circuit breakers is their inability to be bypassed. As E-T-A explains:

"A circuit breaker can't be bypassed like [a fuse], and if it has a trip-free mechanism it can't be held closed manually against an overload".

This design prevents dangerous workarounds, such as using aluminum foil to replace a blown fuse, which could lead to fires. By understanding these differences, you can better determine which device aligns with your specific needs and safety requirements.

Best Use Cases

Fuses are perfect for low-power, sensitive circuits that demand a quick response. Samuel Kenny, Product Manager at OptiFuse, explains that fuses are "a low-cost overcurrent protection option for applications that typically don't have high electricity needs". Their fast reaction time helps protect delicate components like solid-state relays and semiconductor devices from damaging energy surges. MarVac Electronics highlights this benefit:

"Fuses typically have a much more accurate reaction time, which is essential in more sensitive circuits".

Thanks to their compact size, fuses are a great solution for applications where space is limited, such as automotive lighting systems, audio equipment, and control modules in vehicles or marine vessels. Additionally, their lack of moving parts makes them reliable in high-vibration environments where mechanical breakers might falter. For projects where overloads are rare and cost is a concern, fuses stand out as a practical choice. While they shine in low-current, sensitive setups, circuit breakers are better suited for higher power demands and whole-system protection.

On the other hand, circuit breakers excel in scenarios where reliability and ease of reset are essential, particularly in high-power environments. They are commonly used in residential, commercial, and industrial panels to manage variable loads and allow quick resets. For example, double-pole breakers are designed to handle 240-volt appliances like central air conditioners, electric ovens, and clothes dryers. In industrial applications, breakers with electronic trip units offer engineers the ability to fine-tune protection settings, ensuring that only the closest device to a fault trips. This selective coordination minimizes downtime and prevents unnecessary disruptions.

Circuit breakers are especially advantageous in environments prone to frequent overloads. Unlike fuses, which need to be replaced after a single use, breakers can be reset, saving both time and replacement costs. They are also safer for non-specialist personnel, as their enclosed connections reduce the risk of electrocution during resets. John Yoon, PE, Lead Electrical Engineer at McGuire Engineers Inc., highlights their flexibility:

"A circuit breaker can be open and closed against all magnitudes of current, up to its short circuit rating, basically acting as a switching device".

For specific applications, GFCI breakers are recommended in wet areas to enhance safety, while AFCI breakers are ideal for bedrooms to reduce fire risks. This aligns with the earlier discussion on performance and cost-effectiveness, emphasizing the importance of choosing the right device for the job. When sourcing fuses or circuit breakers, platforms like Electrical Trader provide a variety of options, including new and used breakers, transformers, and power distribution equipment. By understanding the strengths of each device, you can make informed decisions tailored to your operational needs.

Conclusion

Choosing the right overcurrent protection device comes down to balancing performance, cost, and safety based on your specific needs. As outlined above, the decision between fuses and circuit breakers hinges on the unique demands of your application.

Fuses are a great fit for sensitive or space-limited setups due to their quick response and lower upfront cost. However, the need to physically replace them after each fault can lead to ongoing labor and inventory expenses. On the other hand, circuit breakers have a higher initial price tag but are more cost-effective in environments prone to frequent faults, as they can simply be reset without requiring new parts. If your system rarely experiences faults and budget constraints are a concern, fuses may be the smarter choice. But for circuits that trip often, circuit breakers offer better long-term value.

Maintenance and safety also play a crucial role in the decision-making process. While fuses require you to stock replacements and perform manual swaps, circuit breakers are virtually maintenance-free. They also provide safer operation by eliminating exposure to live electrical components during resets, making them user-friendly even for those without technical expertise. For applications like semiconductor protection, where even brief surges can cause damage, fuses excel. Meanwhile, residential panels, industrial setups, or systems where downtime impacts productivity often benefit more from the convenience and reliability of circuit breakers.

When you're ready to source either option, Electrical Trader offers a range of new and used fuses, circuit breakers, and power distribution equipment to suit your project needs. By carefully weighing factors like cost, safety, and maintenance, you can choose the solution that ensures your systems operate smoothly and securely.

FAQs

When is it better to use a fuse instead of a circuit breaker?

Fuses are an excellent choice when speedy overcurrent protection, affordability, and space efficiency are top priorities. They operate by melting an internal filament when overheated, breaking the electrical flow almost instantly to safeguard the circuit. This makes them particularly suited for systems where a rapid disconnect is crucial, such as in certain industrial or specialized applications.

Compared to circuit breakers, fuses are generally more budget-friendly and take up less space, which is a big plus in setups with tight budgets or limited room. That said, it’s important to note that fuses are single-use devices. Once they blow, they must be replaced. If you’re looking for a reusable option or need frequent resets due to power surges, a circuit breaker might be the better choice.

What are the cost differences between using fuses and circuit breakers?

Fuses are often the go-to option when you're looking for something with a lower upfront cost. They're an economical choice for initial installation. But there's a catch: every time a fuse blows due to an overcurrent event, it needs to be replaced. If your system deals with frequent overcurrent issues, those replacement costs can pile up over time.

Circuit breakers, in contrast, come with a higher initial price tag. However, they’re designed to be reusable, which means you won’t need to replace them after every use. This feature can significantly reduce ongoing expenses, making circuit breakers a smarter choice for systems that demand durability and can handle repeated resets.

What are the key differences between fuses and circuit breakers in terms of safety and maintenance?

Fuses and circuit breakers both serve the same purpose: protecting electrical circuits from overcurrents. But they operate differently and come with their own set of pros and cons. Fuses use a metal filament that melts when overheated, immediately cutting off the electrical flow. This rapid response enhances safety, but there's a downside - once a fuse "blows", it has to be replaced. And using the wrong type of replacement fuse can introduce risks.

Circuit breakers, however, take a different approach. Instead of melting, they "trip" a switch to disconnect the circuit when a surge occurs. The best part? They can be reset after tripping, which makes them far more convenient and user-friendly for most situations.

When it comes to maintenance, circuit breakers are the clear winner. Unlike fuses, which need to be replaced every time they blow, circuit breakers can simply be reset, saving both time and effort. This also eliminates the risk of accidentally using a fuse with the wrong rating. Circuit breakers shine in scenarios where ease of use and long-term cost savings are priorities. Meanwhile, fuses might still be a good choice for simpler, low-cost setups where space is limited.