Custom Noise Solutions for Large Generators

Share

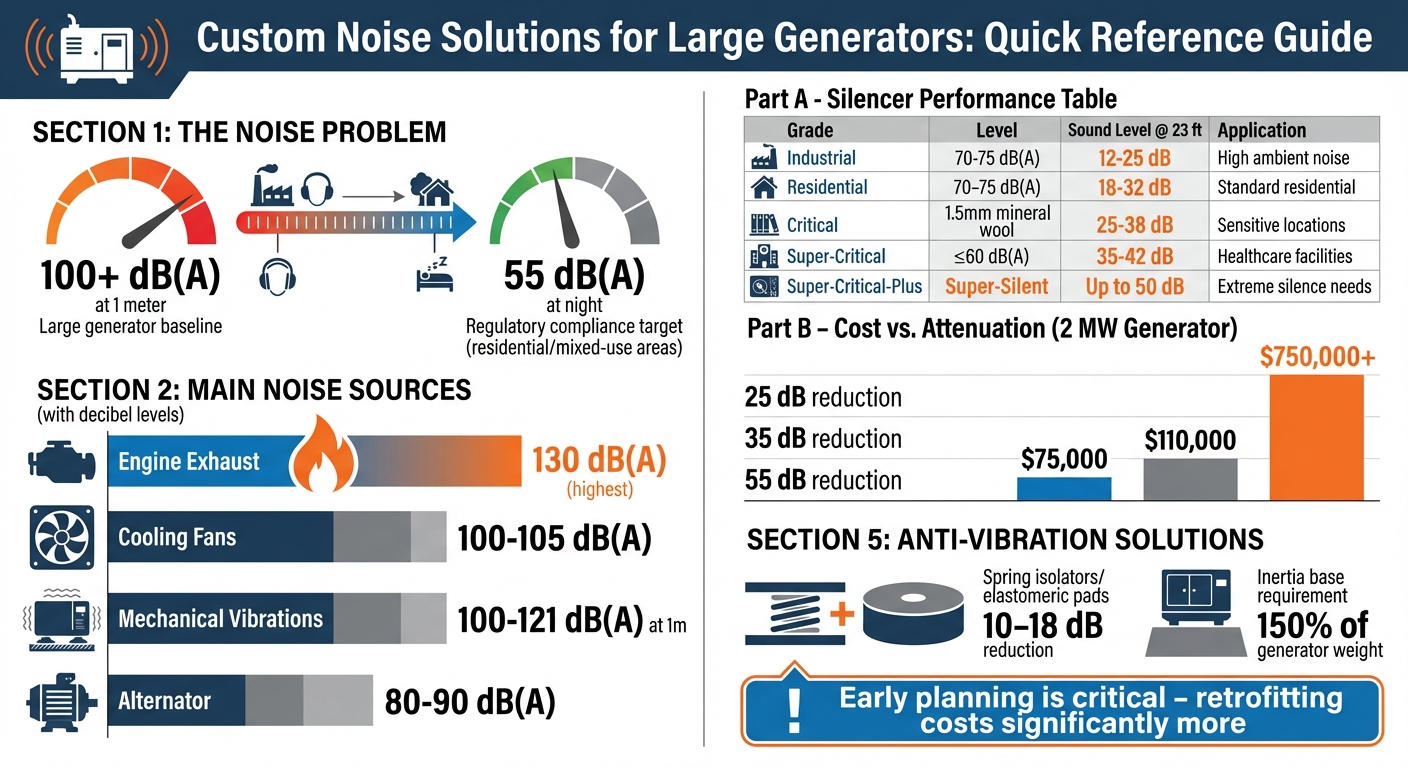

Large industrial generators are loud - often exceeding 100 dB(A) at just 1 meter. This noise can disrupt operations, violate local regulations, and harm workers' hearing. For example, achieving regulatory compliance in residential or mixed-use areas (where limits can drop to 55 dB(A) at night) is a common challenge. Noise control also comes with steep costs: reducing noise by 35 dB for a 2 MW generator can cost $110,000, while a 55 dB reduction may exceed $750,000.

Key noise sources include:

- Engine exhaust: Up to 130 dB(A), especially at low frequencies.

- Cooling fans: 100–105 dB(A) from high-speed airflow.

- Vibrations: Noise transmitted through structures like floors and piping.

Solutions to manage noise:

- Acoustic enclosures: Steel or aluminum shells with sound-absorbing interiors can reduce noise to 60–75 dB(A) at 23 feet.

- Exhaust silencers: Options range from 12–50 dB reduction, depending on the application.

- Anti-vibration mounts: Isolators and inertia bases can cut structure-borne noise by 10–18 dB.

- Sound blankets/panels: Flexible wraps for specific components with high sound absorption.

Planning early and choosing the right combination of solutions is critical for compliance and cost efficiency. Tools like Electrical Trader simplify sourcing enclosures, silencers, and mounts, ensuring all components work together to meet noise reduction goals.

Generator Noise Reduction Solutions: Costs, Performance & Attenuation Levels

Reducing Noise in Power Generation Equipment

Main Sources of Generator Noise

Understanding where generator noise originates is key to implementing effective noise control measures. Large industrial generators produce sound through various mechanical and aerodynamic sources, each contributing to the overall noise profile. Let’s break down the primary sources and their impact.

Engine Exhaust and Mechanical Vibrations

Engine exhaust stands out as the most significant noise source, characterized by low-frequency sounds (31.5 Hz to 250 Hz) that can travel far and penetrate buildings with ease. The mechanical noise from combustion forces and moving engine parts can reach levels between 100 dB(A) and 121 dB(A) at a distance of one meter. These vibrations don’t just stay confined to the engine - they travel through the mounting skid, foundation, and connected components like fuel lines, electrical conduits, and exhaust piping, creating structure-borne noise.

As one expert from Consulting-Specifying Engineer explains:

"Vibration is the most pervasive source of noise produced by a genset." – Consulting-Specifying Engineer

This vibration transmission makes noise mitigation particularly tricky, as every connection point requires specialized isolation to reduce the spread of sound.

Blowers, Pumps, and Gearboxes

Cooling fans are the next major noise contributor, typically producing 100 dB(A) to 105 dB(A) at one meter. These high-speed fans move massive amounts of air - up to 706 cubic feet per second for larger engines - creating significant airborne noise. The turbulence caused by air passing over radiator fins further amplifies the sound.

The alternator also adds to the noise, generating between 80 and 90 dB(A). This happens in two ways: windage noise from the rotor spinning past stationary poles and induction noise caused by current fluctuations in the windings.

Ventilation and Enclosure Design Issues

Ventilation openings in generator enclosures are another critical source of noise. Generators require substantial airflow for combustion and cooling; for instance, a 500 kVA unit may need about 530 cubic feet per second of airflow. Without proper acoustic solutions like baffles or labyrinth paths, these openings allow noise to escape freely.

Poorly designed enclosures only make the problem worse. Thin materials often fail to block low-frequency noise effectively, and direct line-of-sight paths between cooling fans and exterior louvers provide an easy escape route for sound. Additionally, unsealed penetrations for fuel lines, exhaust pipes, and electrical connections create gaps that reduce the enclosure’s ability to contain noise. Striking the right balance between noise reduction and sufficient airflow is a tough engineering challenge since overly restrictive designs can lead to overheating or reduced engine performance.

These noise pathways highlight the importance of targeted strategies to address each source effectively.

Custom Noise Reduction Solutions

Reducing generator noise effectively often requires tailored solutions that align with specific needs, budgets, and site conditions. These methods, when combined with earlier strategies, create a well-rounded approach to noise control. By focusing on individual noise sources, these solutions ensure compliance and improve operational efficiency.

Acoustic Enclosures for Full Noise Control

Acoustic enclosures provide a comprehensive way to manage noise. They rely on a combination of tough exterior materials, like steel or aluminum, to block sound and interior linings made of materials like mineral wool or fiberglass to absorb sound by converting it into heat.

The type of enclosure you choose makes a significant difference. For example, a residential-grade enclosure with 1 mm (0.04 in) thick steel walls and 50 mm (2 in) mineral wool can lower noise levels to 70–75 dB(A) at about 23 feet. In contrast, a super-silent enclosure, featuring 2 mm (0.08 in) steel and composite insulation, can bring noise levels down to 60 dB(A) or even less at the same distance. Steel tends to perform better than aluminum by reducing noise an additional 2–3 dB, thanks to its higher mass and stiffness. However, aluminum may be a better choice in coastal settings due to its resistance to corrosion.

| Enclosure Class | Typical Sound Level @ 23 ft | Construction Materials |

|---|---|---|

| Residential | 70–75 dB(A) | 1 mm (0.04 in) steel, 50 mm (2 in) mineral wool, standard muffler |

| Critical / Hospital | 65 dB(A) | 1.5 mm (0.06 in) steel, 75 mm (3 in) mineral wool, high-performance silencer |

| Super-Silent | ≤60 dB(A) | 2 mm (0.08 in) steel, composite insulation with mass-loaded vinyl |

These enclosures also use baffled inlets to maintain airflow while minimizing sound escape.

Sound Attenuation Blankets and Panels

For specific components, sound attenuation blankets and panels are a flexible and cost-effective choice. These wraps not only reduce noise but also provide thermal insulation, making them ideal for parts like engine blocks, gearboxes, and piping that cannot be fully enclosed. Most of these materials feature dense cores with a Noise Reduction Coefficient (NRC) of 0.85 or higher.

One big advantage is their removability, allowing maintenance without compromising their performance. However, these materials should never be painted or sealed, as this would cause them to reflect sound instead of absorbing it.

Anti-Vibration Mounts and Exhaust Silencers

Structure-borne noise can travel through floors, foundations, and connected piping, but vibration isolation can help. Spring isolators or elastomeric pads placed between the generator and its mounting structure can reduce noise transmission by 10 to 18 decibels when properly sized. For installations on upper floors or sensitive areas, an inertia base - a reinforced concrete-filled steel frame weighing at least 150% of the generator's weight - offers even greater damping.

Exhaust silencers are another critical solution, tackling one of the loudest noise sources directly. Without treatment, engine exhaust noise can reach 120–130 dB. Silencers use reactive designs to manage low-frequency noise and absorptive designs for high-frequency noise, breaking up pressure waves. Their effectiveness varies depending on the application:

| Silencer Grade | Noise Reduction (dB) | Typical Application |

|---|---|---|

| Industrial | 12–25 dB | Areas with high ambient noise |

| Residential | 18–32 dB | Standard residential areas |

| Critical | 25–38 dB | Quiet environments or sensitive locations |

| Super-Critical | 35–42 dB | Healthcare and high-sensitivity sites |

| Super-Critical-Plus | Up to 50 dB | Extreme silence requirements |

When selecting high-attenuation silencers, ensure they don’t exceed the engine’s back-pressure limits, as this could affect performance. Additionally, all fuel lines, exhaust pipes, and electrical conduits should use flexible, metallic braided connections to prevent vibration from bypassing isolation mounts.

For a 2 MW generator, costs can vary significantly depending on the level of noise reduction needed. A 25 dB attenuation setup might cost around $75,000, while achieving 35–40 dB could run about $110,000. For extreme noise reduction of 55 dB, costs may exceed $750,000. Dennis Aaberg, a Senior Acoustics Specialist at Cummins Power Generation Inc., emphasizes the importance of early planning:

"The high cost of retrofitting a site for noise reduction makes it imperative to assess noise performance requirements early in the on-site power system design stage." – Dennis Aaberg, Senior Acoustics Specialist, Cummins Power Generation Inc.

Finally, sealing all gaps and cracks is crucial. Use non-hardening elastomeric caulking to ensure there are no weak points that could compromise noise control.

sbb-itb-501186b

Using Electrical Trader for Custom Solutions

Once you've explored strategies for reducing noise, Electrical Trader offers a straightforward way to source the specialized components needed to bring those plans to life.

Products for Power Generation and Noise Control

When it comes to controlling noise from generators, having access to the right components is crucial. Electrical Trader provides a one-stop marketplace where professionals can find industrial generators ranging from 5 kVA to 3,000 kVA, along with acoustic enclosures, sound-attenuated containers, and weatherproof housings.

These products complement key noise control tools like acoustic enclosures, exhaust silencers, and anti-vibration mounts. For example, exhaust silencers are available in a range of attenuation levels, from industrial-grade (12–25 dB reduction) to super-critical-plus (up to 50 dB reduction). Meanwhile, vibration control options include anti-vibration mounts, neoprene and cork pads, high-compliance springs, and inertia bases. Additional accessories are also available to fine-tune noise reduction efforts.

When selecting materials, focus on those with absorption coefficients of 0.75 or higher for effective sound dampening. High-quality acoustic enclosures, for instance, can reduce noise by as much as 59.9 dB at 5,000 Hz, making them suitable for even the most demanding environments.

Simplified Procurement Through Electrical Trader

Coordinating all the necessary elements - such as silencers, enclosures, and isolation mounts - can be a complex task, especially when they need to work together seamlessly to achieve the desired noise reduction. Electrical Trader simplifies this process by organizing products into clear categories, making it easy to compare specifications, materials, and attenuation levels.

Before making a purchase, it's important to gather data from the generator manufacturer, including mechanical and combustion air exhaust details, to ensure that any chosen enclosure meets specific decibel reduction requirements at the desired distance. For setups involving multiple generators, always base your solution on the loudest unit to ensure consistent results.

The platform also offers a mix of new and used equipment, allowing professionals to balance performance needs with budget constraints. For example, the costs of noise attenuation for a 2 MW generator can range from $75,000 for a 25 dB reduction to over $750,000 for a 55 dB reduction. By offering access to both new and pre-owned components, Electrical Trader provides flexibility in meeting noise control goals without unnecessary spending. This centralized approach ensures that all the essential parts are easy to compare and procure, helping professionals meet advanced noise reduction standards efficiently.

Conclusion: Meeting Noise Requirements with Custom Solutions

Tackling noise control effectively begins with pinpointing the main source - whether it's exhaust noise, mechanical vibrations, or fan output. Skipping this step can lead to costly solutions that fail to deliver results.

Once the primary noise source is identified, tailored solutions provide better outcomes. Using specific materials like porous absorbers or added mass elements can outperform generic approaches. Combining methods such as acoustic enclosures, properly rated exhaust silencers (ranging from industrial-grade with 12–25 dB reduction to super-critical-plus models offering up to 50 dB), and anti-vibration mounts ensures comprehensive noise control. These measures address both airborne and structure-borne noise, preventing vibrations from bypassing acoustic barriers and helping meet regulations like the 55 dB(A) nighttime limit in mixed-use areas.

Cost and performance must go hand in hand. The expense of noise reduction depends on how much sound needs to be mitigated, and Electrical Trader simplifies the process of finding solutions that fit your needs. Instead of juggling multiple suppliers for silencers, enclosures, and vibration mounts - and risking compatibility issues - you can compare options side-by-side on a single platform. This centralized approach ensures all components work together to hit your noise reduction targets, avoiding the costly retrofits that arise when noise control is treated as an afterthought. Electrical Trader’s streamlined sourcing makes it easier to design an effective and cost-efficient noise control strategy from the start.

FAQs

What are the best ways to reduce noise from large industrial generators without overspending?

Reducing noise from large industrial generators can be done efficiently and without breaking the bank by using a few practical methods. One popular solution is adding sound-attenuated enclosures or acoustic barriers. These are designed to trap and absorb noise while still allowing for proper ventilation and cooling, ensuring the generator continues to operate smoothly.

Another smart and budget-friendly tactic is strategic placement. By positioning the generator as far as possible from noise-sensitive areas, you can naturally reduce the sound levels due to distance. On top of that, installing silencers or mufflers on the exhaust system is a straightforward way to cut down noise without requiring major changes to the generator's setup.

By combining these methods - acoustic enclosures, careful placement, and exhaust silencers - you can effectively manage generator noise in a wide range of settings.

What factors influence noise reduction and material choices for acoustic enclosures in large generators?

Acoustic enclosures for large generators are built to tackle noise reduction effectively. Their success depends on thoughtful design, sturdy construction, and carefully chosen materials. While standard enclosures can cut noise levels by about 15-20 dB, more advanced designs - like double-walled structures equipped with sound-absorbing materials and vibration isolators - can bring noise reduction to an impressive 60-80 dB.

These enclosures often use tough metals like steel or aluminum for the outer shell, combined with sound-dampening linings such as acoustic foam or mineral wool to limit airborne noise. To maintain proper generator function, they also include features like ventilation systems, silencers, and baffles, which balance cooling and airflow needs with noise control. A well-designed enclosure ensures quieter operation while still allowing easy access for maintenance and preserving generator performance.

Why is it important to plan for generator noise control early in the installation process?

Planning for noise control right from the beginning of a generator installation is smart and economical. Tackling noise issues during the design phase is not only easier but also significantly less expensive than making changes after everything is in place.

By identifying noise sources early - like the engine, exhaust system, cooling fans, and vibrations - you can put measures in place to reduce disruptions and stay within local noise regulations and zoning requirements. This proactive approach also helps avoid complaints from neighbors and costly fixes down the road. Starting with noise control in mind sets the stage for a smoother installation and better long-term performance.