5 Challenges in Switching Generators to Alternative Fuels

Share

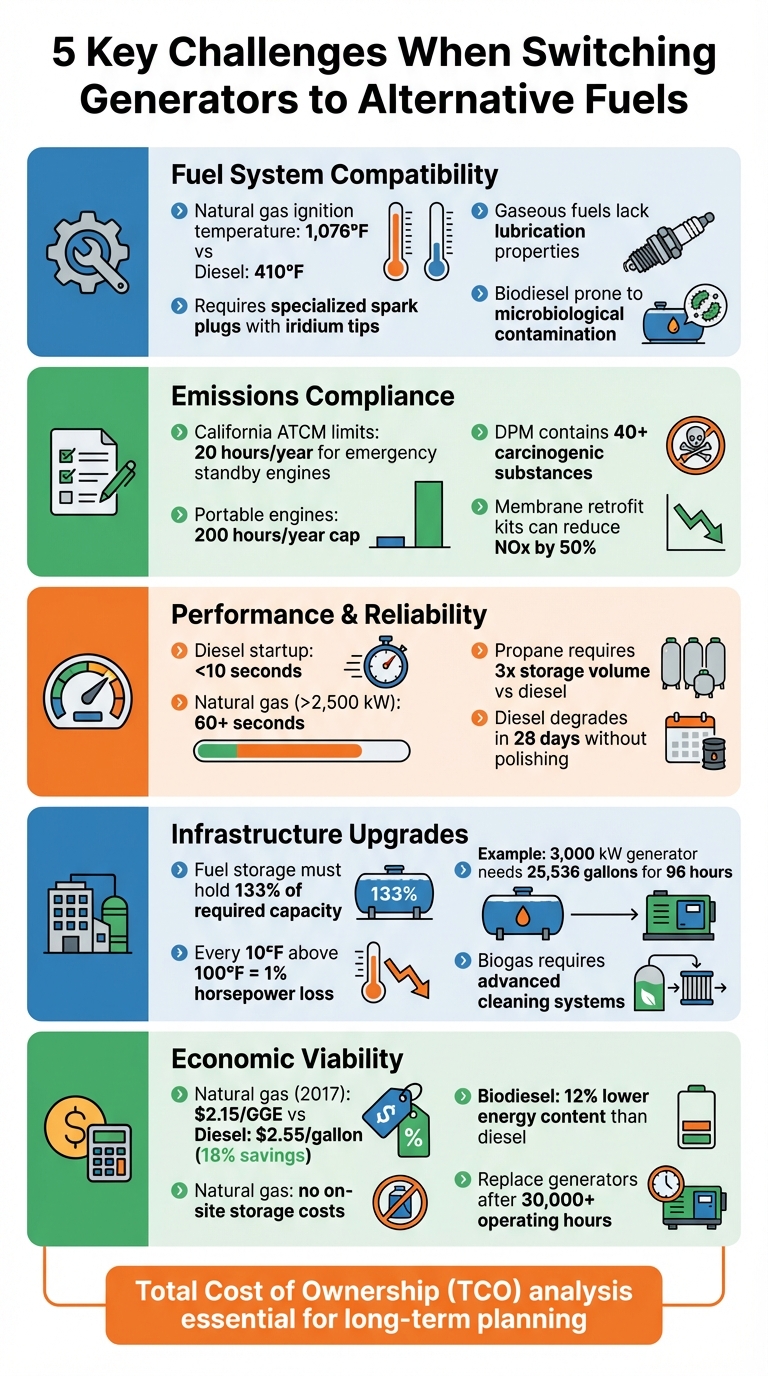

Switching generators to alternative fuels can improve emissions and fuel efficiency, but it’s not without hurdles. Here are the five main challenges you’ll face:

- Fuel System Compatibility: Existing hardware, like injectors and combustion systems, often requires significant modifications to handle alternative fuels like natural gas, biodiesel, or hydrogen blends. These fuels differ in energy density, ignition temperatures, and lubrication properties, demanding specialized components and materials.

- Emissions Compliance: Meeting federal and state-specific emissions standards, such as California’s strict Airborne Toxic Control Measure (ATCM), can be costly and complex. Adjusting systems to reduce pollutants like nitrogen oxides (NOx) often creates trade-offs, such as increased particulate matter.

- Performance and Reliability: Alternative fuels can impact generator response times, energy density, and startup speed. For instance, natural gas generators often take longer to start and respond to load changes compared to diesel systems, which could be an issue for critical applications.

- Infrastructure and Safety Upgrades: Switching fuels may require new storage tanks, piping systems, and safety features. Fuels like biogas need advanced cleaning systems, while natural gas systems demand high-pressure fuel supply and additional safety protocols.

- Economic Viability: While natural gas offers lower fuel costs and eliminates the need for on-site storage, upfront retrofitting expenses, maintenance needs, and lifecycle risks must be carefully analyzed. Total Cost of Ownership (TCO) assessments are essential to determine long-term savings.

Switching fuels is a complex process requiring careful planning, regulatory compliance, and infrastructure updates. While the potential benefits are clear, addressing these challenges is key to a successful transition.

5 Key Challenges When Switching Generators to Alternative Fuels

How To Convert Your Generator to Natural Gas or Propane

1. Fuel System Compatibility and Hardware Modifications

Switching from diesel to alternative fuels requires significant changes, starting with the fuel injectors. Diesel injectors aren't compatible with gaseous fuels due to their lower energy density and the need for different flow rates and metering processes.

Natural gas, for example, has a much higher ignition temperature - 1,076°F compared to diesel's 410°F. This difference means engines need specialized spark plugs, often with iridium tips, and combustion components made from high-temperature-resistant materials like high-silicon molybdenum or stainless steel. Generac has tackled these challenges by replacing multi-point port injection systems with throttle body injection or traditional fuel mixers.

Another hurdle with gaseous fuels is their lack of lubrication, which can increase wear on valves and valve seats. Additionally, these fuels burn more slowly, requiring advanced engine timing to ensure combustion finishes before the exhaust valves open.

In November 2020, Siemens Energy upgraded its SGT-600, -700, and -800 turbines with third-generation DLE burners. These modifications allow the turbines to handle hydrogen blends of up to 75%.

Biodiesel, on the other hand, presents its own set of challenges. Low-sulfur biodiesel is particularly prone to microbiological contamination, which can lead to corrosion, clogged filters, and even safety shutdowns. To combat these issues, facilities often rely on regular fuel polishing and use nonmetallic piping, such as reinforced thermosetting resin, for underground installations.

These hardware and system updates form the technical groundwork for addressing emissions compliance and optimizing performance.

2. Emissions Compliance and Regulatory Requirements

Upgrading generators to meet emissions standards is no easy task. While federal EPA regulations set the groundwork, state and local agencies often enforce stricter, region-specific rules. Take California, for instance - its Airborne Toxic Control Measure (ATCM) for Stationary Compression Ignition Engines applies to units over 50 brake horsepower (bhp) and sets strict limits on diesel particulate matter (DPM). DPM is particularly concerning because it contains over 40 substances known to cause cancer.

Under California's ATCM, stationary emergency standby engines are restricted to just 20 hours of maintenance and testing annually, while portable "low-use" engines are capped at 200 hours per year, excluding emergencies. These tight restrictions complicate retrofitting efforts, as they limit the operational hours needed to test and ensure retrofitted systems perform reliably under actual conditions.

Navigating these regulations requires a delicate balance between controlling emissions and maintaining performance.

"Many of these gen-sets are being rapidly installed with minimal concern for EPA emissions and exclusively focus on providing back-up power to avoid blackouts." - US EPA

Reducing nitrogen oxides (NOx) through adjustments like turbocharger tuning and engine timing often leads to an unintended rise in particulate matter, which poses additional challenges for system reliability. For example, an EPA-funded project demonstrated that membrane retrofit kits could cut NOx emissions by 50% while keeping other pollutants in check. However, proving the long-term dependability of these systems remains a hurdle for facility operators.

For those considering fuel changes, checking local air quality permits is essential. In California, the Portable Equipment Registration Program (PERP) offers a solution for portable generators. It allows statewide operation without needing individual district permits, as long as engines meet certification standards and don’t stay in one location for more than 12 consecutive months.

3. Performance, Reliability, and Load Response

Switching to alternative fuels significantly impacts how generators perform and respond to load demands. Diesel generators are known for their quick transient response times, outperforming other fuel types in this regard. On the other hand, natural gas generators, especially those above 150 kW, tend to react more slowly, which can be a challenge in systems requiring rapid adjustments. These differences make it crucial to carefully design systems to handle sudden load changes effectively.

One major hurdle is startup speed. Emergency systems typically demand generators to start and supply power within 10 seconds. Diesel generators consistently meet this requirement, making them a reliable choice. However, natural gas units, particularly those exceeding 2,500 kW, often take 60 seconds or more to become operational. For facilities where immediate power is vital, this delay could pose a significant issue.

"The generator set [Natural Gas] will also take longer to change speed to account for changes in load. This disadvantage will be less problematic for supplying continuous loads, which do not vary frequently." - Lilly Vang and Joshua Hunter, Electrical Engineers, CDM Smith

Energy density introduces another layer of complexity. Propane, for instance, requires more than triple the storage volume of diesel to deliver the same energy output. This means larger storage tanks or more frequent refueling, which can complicate retrofitting efforts. Natural gas, delivered through pipelines, avoids storage concerns entirely. However, individual natural gas generators typically produce less wattage compared to their diesel counterparts. To compensate, operators often install multiple natural gas units in parallel. While this approach offers flexibility, it also drives up initial installation costs.

Fuel quality and stability over time are additional considerations. Diesel fuel can degrade within 28 days and may become unusable without regular fuel polishing. In contrast, natural gas delivered via underground pipelines doesn’t have shelf-life issues. This makes natural gas a better option for long-term use, though its slower response to sudden load changes remains a critical drawback for facilities with urgent power demands.

sbb-itb-501186b

4. Infrastructure, Safety, and Facility Upgrades

Switching generators to alternative fuels often demands significant infrastructure adjustments. For instance, fuel storage options like Aboveground Storage Tanks (ASTs) and Underground Storage Tanks (USTs) come with distinct trade-offs. ASTs are cheaper to install but pose higher fire risks, requiring compliance with UL 2080 or UL 2085 standards. On the other hand, USTs minimize fire hazards but necessitate leak detection systems, corrosion protection, and more complex maintenance. According to NFPA 110, emergency fuel storage must hold 133% of the fuel needed for the generator's full-rated load and duration. For example, a 3,000 kW generator consuming 200 gallons per hour would require 25,536 gallons for 96 hours of operation. Beyond storage, ensuring efficient fuel transport and temperature management is equally important.

Fuel transport systems call for careful engineering. Underground piping generally uses double-wall designs with interstitial leak monitoring, while aboveground systems often rely on single-wall carbon steel, though some local codes may mandate double-wall construction. Safety features like foot valves, anti-siphon valves, and fusible link shutoff valves are essential. Additionally, temperature control is critical: every 10°F rise above 100°F reduces engine horsepower by roughly 1%. If fuel temperatures exceed 140°F–150°F, external fuel coolers or return pumps are necessary to maintain performance.

For biogas systems, the infrastructure demands are even more specialized. In Riverside, California, a biogas fuel cell system at the city’s water quality control plant relies on equipment designed to remove siloxanes and sulfur compounds before powering generators. Operators commend its responsiveness and ease of maintenance. Similarly, Tulare, California, has shown how wastewater treatment facilities can use anaerobic digester gas to generate power, but only after investing in advanced gas cleaning systems. These examples highlight the need for custom-built safety measures and startup procedures tailored to biogas applications.

Safety protocols differ depending on the fuel type. For natural gas generators, start-time delays are crucial to reduce explosion risks. Level 1 emergency systems must include an externally placed E-Stop to prevent accidental activation. Additionally, generator rooms should maintain a minimum temperature of 40°F, often requiring dedicated heating systems, and generators should be located outdoors to avoid hazardous carbon monoxide buildup.

Beyond equipment upgrades, regulatory compliance is key to a smooth retrofitting process. Early collaboration with Authorities Having Jurisdiction (AHJs) and fire department officials can prevent costly redesigns down the line. Local codes often dictate tank placement, property line setbacks, and fire protection requirements. For critical applications like data centers, redundancy is essential - this can include multiple fuel tanks and dual independent Programmable Logic Controllers (PLCs) to eliminate single points of failure. Facilities storing flammable liquids must also adhere to strict safety measures: using labeled safety containers outside living spaces and installing battery-operated CO alarms with backup power in nearby buildings.

5. Economic Viability and Lifecycle Risk

Switching generators to alternative fuels requires a close look at both upfront installation costs and long-term expenses. Natural gas generators are generally cheaper to install than diesel systems because they connect directly to underground utility pipelines. This eliminates the need for costly on-site storage tanks and spill containment systems. On top of that, securing air-quality permits for diesel generators is often more expensive and complicated due to their higher emissions. Natural gas systems, with fewer regulatory challenges, can significantly reduce pre-operational costs.

Fuel prices play a major role in determining overall cost-effectiveness. Back in April 2017, the national average price of natural gas was $2.15 per GGE, compared to $2.55 per gallon for diesel - a difference of 18%. Since then, this gap has grown, making natural gas an increasingly appealing option for facilities aiming to cut costs. However, newer alternatives like green hydrogen face hurdles. Roxana Shafiee, a Postdoctoral Fellow at Harvard University Center for the Environment, explains:

"Even if production costs decrease in line with predictions, storage and distribution costs will prevent hydrogen being cost-competitive in many sectors".

Maintenance costs also differ significantly depending on the fuel. Diesel fuel requires regular "polishing" every 12 to 16 months to remove impurities and has a shelf life of about one year. Natural gas, on the other hand, avoids these recurring costs entirely since it doesn’t degrade over time. Biodiesel introduces another challenge, as its 12% lower energy content compared to standard diesel means higher fuel consumption.

To decide whether retrofitting is worth it, a Total Cost of Ownership (TCO) analysis is crucial. This assessment should include installation expenses, fuel prices, maintenance schedules, and any infrastructure upgrades required for your specific facility. For generators that have logged over 30,000 hours of operation, replacing them often makes more sense financially, as newer models tend to be more efficient and require less maintenance. Another cost-saving approach is using multiple smaller generators in parallel. This "pay-as-you-grow" setup allows facilities to add power capacity incrementally, avoiding the need for upfront investment in oversized systems.

Another aspect to consider is supply chain reliability, which plays a big role in lifecycle risk. Diesel systems typically store enough fuel for just 2–3 days and rely on truck deliveries that can be disrupted by weather or other emergencies. In contrast, natural gas pipelines offer a steady supply that can last weeks or even months and are rarely impacted by weather events. This reliability makes natural gas a strong contender for facilities where uninterrupted power is non-negotiable.

Sourcing Retrofitted and Alternative Fuel-Ready Equipment

Choosing the right generator for alternative fuels requires a close look at regulatory compliance and fuel compatibility. Any retrofitted equipment must meet emissions standards set by agencies like the U.S. Environmental Protection Agency (EPA), the National Highway Traffic Safety Administration (NHTSA), and state-level organizations such as the California Air Resources Board (CARB). Whether you opt for factory-built alternative fuel models or aftermarket conversions, your decision will directly influence compliance, performance, and the integration challenges previously discussed.

Platforms like Electrical Trader simplify the process by offering a centralized marketplace for new and used power generation equipment, including generators, switchgear, and transformers. Natural gas generator sets, for instance, are available in configurations ranging from compact 150 kW units to heavy-duty 1,500 kW systems. Pricing examples include a 150 kW Cummins natural gas generator, starting at about $35,000, and a 550 kW Caterpillar G3512, which ranges from $85,000 to $250,000. For Tier 4 Final-compliant diesel units capable of running on renewable HVO fuel, a 100 kW Caterpillar XQ125 is priced around $55,000.

When buying used equipment, it's crucial to verify operational history and emissions tier ratings. Listings often include total run-time (e.g., "Under 4,000 Hours" vs. "9,000 Hours") to help gauge remaining lifespan. Maintenance logs are equally important, as they document testing and demand response run-times - key for ensuring compliance with federal limits on non-emergency use, typically capped at 100 hours annually. Additionally, confirm the EPA Tier rating and check local air quality standards, which can be especially strict in areas like Houston or Dallas.

Fuel conversion requires more than just the generator. Supporting components such as transformers and circuit breakers must also be compatible. Platforms like Electrical Trader offer these components from manufacturers like ABB, Eaton, GE, and Square D, with filters for technical specifications like kVA rating and voltage. For example, reconditioned 1,000 kVA three-phase transformers are available for $12,999 to $13,999, providing a budget-friendly option. Some vendors even include one-year warranties on reconditioned switchgear and transformers, helping to manage costs during the transition.

Finally, confirm that the generator is engineered for your specific fuel type. Dedicated natural gas models like the Caterpillar G3512 or Cummins GTA38 are designed for optimal performance, unlike generic conversions. For used diesel units, ensure they are certified for HVO, and for gaseous units, verify they are calibrated for the specific BTU ratings of the natural gas available in your area. Additionally, check with local Authorities Having Jurisdiction (AHJs) to ensure that alternative fuels like natural gas are recognized for off-site fuel storage in your region. This level of scrutiny ensures that your equipment is fully aligned with the retrofitting challenges already highlighted.

Conclusion

Switching generators to alternative fuels comes with a set of challenges that must be carefully addressed: fuel system compatibility, emissions compliance, performance reliability, infrastructure upgrades, and economic feasibility. Among these, ensuring regulatory compliance is absolutely critical. Always consult your local Authority Having Jurisdiction (AHJ) before making any changes to avoid costly shutdowns or legal complications.

Beyond regulatory and technical considerations, understanding the financial implications is equally important. Conducting a Life Cycle Cost Analysis (LCCA) can provide valuable insights. For example, while a 2,500 kW natural gas generator might cost about 45% more than a Tier 2 diesel unit, it’s only around 5% more than a Tier 4 diesel option. Plus, natural gas generators often offer lower operational costs over time. However, don’t overlook necessary infrastructure upgrades, like gas booster pumps, if the local utility can’t supply high-pressure fuel.

To minimize risks further, seeking guidance from industry experts is a smart move. Professionals can help navigate technical challenges, like the slower transient response times of natural gas engines or the complexities of Tier 4 emissions systems, which can shut down due to even minor component issues. Additionally, sourcing equipment with a verified operational history and documented emissions ratings can help reduce uncertainties.

Transitioning to alternative fuels requires careful planning and a strategic approach. By addressing each challenge thoughtfully and leaning on expert advice, you can reduce risks and set your facility up for reliable, long-term success.

FAQs

What modifications are needed to make a generator compatible with alternative fuels?

Switching a generator to run on alternative fuels like natural gas, propane, biodiesel, or bi-fuel blends involves several important system upgrades. For starters, you’ll need to replace or resize the fuel tank to ensure it’s compatible with the chemical properties of the new fuel. Additionally, upgrading pumps and filters is essential to handle differences in viscosity and particulate levels. You might also need to modify or replace fuel delivery components - like injectors or carburetors - to align with the combustion characteristics of the chosen fuel.

Other necessary changes could include upgrading piping and hoses to materials that can handle the new fuel type, installing pressure regulators or control valves to maintain the correct pressure, and adding heating or cooling systems for fuels that are temperature-sensitive. Since these upgrades often require specialized equipment, Electrical Trader provides a wide range of fuel system parts - such as pumps, filters, and control modules - to simplify the retrofitting process while ensuring compliance with U.S. standards.

What are the key differences in emissions compliance when switching from diesel to alternative fuels for generators?

Compliance rules for emissions vary greatly between diesel generators and those modified to run on alternative fuels like natural gas or propane. Diesel generators are subject to the EPA's nonroad compression-ignition standards, which set strict limits on pollutants such as nitrogen oxides (NOx), particulate matter, and carbon monoxide (CO). To operate legally, these generators also need a Certificate of Conformity.

On the other hand, generators powered by alternative fuels are regulated under the EPA's New Source Performance Standards (NSPS) for stationary spark-ignited engines. These standards come with different pollutant limits, certification protocols, and often rely on state-level permitting processes instead of the federal diesel certification. Knowing these distinctions is essential to ensure compliance and to avoid potential setbacks when converting generators to alternative fuel systems.

What are the cost factors and potential savings of converting generators to alternative fuels?

Switching a generator to alternative fuels like natural gas, bi-fuel, or landfill gas can mean balancing upfront costs with long-term savings. The initial investment usually includes the generator itself and any necessary fuel-handling equipment. For smaller systems (under 150 kW), natural gas generators are often priced competitively. However, for larger systems, costs can jump by 30%–60%, mainly due to higher equipment prices and more complex installation requirements. If you're planning to use waste gases, like landfill gas, additional pretreatment might be necessary. The cost of this depends on the gas composition and the size of the system, adding another layer to the initial expense.

On the savings side, natural gas is typically cheaper than diesel in the U.S. and tends to have more stable pricing. Generators powered by gas also come with lower maintenance needs - fewer oil changes, less frequent filter replacements - and often bypass emissions compliance fees that diesel units might incur. These factors can reduce the total cost of ownership by 10%–20% over time, depending on fuel prices, generator size, and whether gas-conditioning infrastructure is needed. For those looking to make the switch, Electrical Trader streamlines the process of sourcing conversion kits and parts, helping you tap into these savings with ease.