ANSI Z540 vs. NIST Standards

Share

ANSI Z540 and NIST standards are two key frameworks in the U.S. calibration industry, but they serve different purposes:

- NIST: Focuses on defining measurement standards and ensuring traceability to SI units through an unbroken calibration chain.

- ANSI Z540: Provides guidelines for calibration labs, emphasizing quality systems, risk management, and compliance with specific requirements like the 4:1 Test Uncertainty Ratio (TUR).

Key Differences:

-

Scope:

- NIST ensures measurement accuracy and traceability.

- ANSI Z540 defines lab procedures and management systems.

-

Requirements:

- NIST: Documented uncertainty and traceability.

- ANSI Z540: TUR or Probability of False Acceptance (PFA), quality manuals, and audits.

-

Applications:

- NIST: General calibration needs.

- ANSI Z540: High-precision fields like aerospace and defense.

Quick Comparison Table:

| Feature | NIST | ANSI Z540 |

|---|---|---|

| Nature | Federal agency | Documentary standards |

| Primary Scope | Measurement standards and traceability | Lab management and calibration systems |

| Key Focus | Traceability to SI units | 4:1 TUR, PFA, risk management |

| Applications | General calibration | High-stakes industries like defense |

For routine calibration, NIST traceability suffices. For critical industries, ANSI Z540 compliance is often required. Always check contractual obligations to determine the appropriate standard.

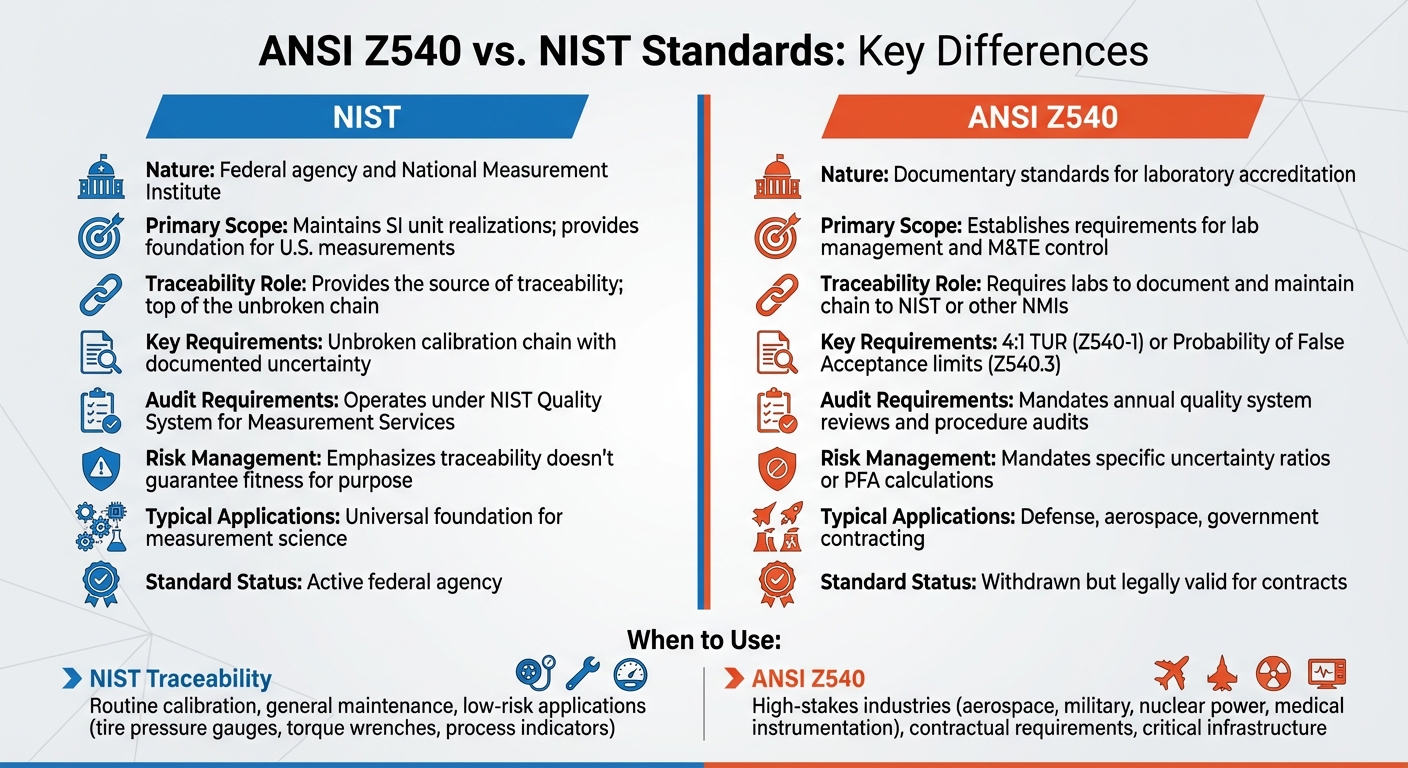

ANSI Z540 vs NIST Standards Comparison Chart

Calibration Traceability and Standards Compliance

ANSI Z540 Requirements

The ANSI Z540 standards outline procedures for calibration laboratories in the U.S., ensuring both quality and precision in their operations. This family of standards includes Z540.1-1994, which focuses on general quality system requirements, and Z540.3-2006, which introduces advanced risk management practices. These guidelines replaced the military standard MIL-STD-45662A and are widely used in military and commercial contracts across North America. Randy Long, Accreditation Manager at ANAB, notes:

"Z540-1 was withdrawn as a standard but is still in force with many military contracts".

Organizations like the U.S. Navy and NASA continue to require compliance with Z540.3 for high-precision calibration tasks. Below, we’ll break down the key aspects of Z540.1 and the risk management updates introduced in Z540.3.

ANSI Z540.1-1994: General Requirements

Z540.1 establishes the essential framework for calibration laboratory procedures, focusing on quality assurance, proper documentation, and traceability. The standard is divided into two parts: Part I aligns with ISO/IEC Guide 25, while Part II incorporates specific requirements from the now-retired MIL-STD-45662A.

One key requirement is the 4:1 Test Uncertainty Ratio (TUR). This means the uncertainty of the measurement standards must not exceed 25% of the acceptable tolerance for the equipment being calibrated. For instance, if calibrating a voltmeter with a tolerance of ±0.1 V, the calibration standard’s uncertainty must be ±0.025 V or less. If this ratio cannot be achieved, explicit customer approval is required.

Additionally, laboratories must maintain a quality manual, perform annual reviews, and set appropriate calibration intervals. If any equipment is found to be significantly out of tolerance during calibration, labs are required to notify customers in writing and provide detailed measurement data for corrections. Subcontractors must also comply with Z540, and customers must be informed of their involvement. These foundational practices paved the way for the more advanced risk management measures introduced in Z540.3.

ANSI Z540.3-2006: Risk Management Updates

Z540.3 builds on the quality systems outlined in Z540.1 by emphasizing risk management. This standard replaces Part II of Z540.1 and introduces more rigorous protocols for managing potential risks.

One major addition is the use of Probability of False Acceptance (PFA) calculations. This metric evaluates the risk of mistakenly accepting equipment as within tolerance when it is actually out-of-spec. As explained by NSCA Technologies & Tra-Cal Lab:

"METCAP laboratories apply the requirements of ANSI Z540.3 and calculate the probability of false acceptance (PFA) for their own measuring and test equipment and when making statements of compliance on reports and certificates for customers".

Z540.3 also requires labs to document "as-found" and "as-left" conditions, capturing the state of equipment both before and after calibration. Subclause 5.3 outlines detailed expectations for calibration procedures, measurement assurance, uncertainty analysis, and traceability, all designed to meet the highest accreditation standards.

These updates ensure that calibration processes not only meet quality benchmarks but also effectively manage and minimize risks.

NIST Traceability Requirements

NIST traceability ensures measurement accuracy by connecting results to SI units through a documented, unbroken calibration chain. Unlike the broader laboratory management systems outlined in ANSI Z540, NIST traceability zeroes in on the accuracy lineage of the measurements themselves.

The International Vocabulary of Metrology (VIM) describes metrological traceability as:

"property of a measurement result whereby the result can be related to a reference through a documented unbroken chain of calibrations, each contributing to the measurement uncertainty".

This concept applies specifically to the measurement values recorded during calibration, not to all subsequent measurements. NIST emphasizes this distinction, stating:

"Merely having an instrument calibrated, even by NIST, is not enough to make the measurement result obtained using that instrument traceable to realizations of the appropriate SI unit".

To establish valid NIST traceability, seven key elements must work together seamlessly. Each calibration step in the chain must adhere to documented and validated procedures carried out by technically competent laboratories. Every step must account for measurement uncertainty, verified through regular recalibrations. The final link in the chain must connect to SI units, as realized by NIST or another recognized national metrology institute. NIST collaborates with over 100 national metrology labs worldwide, such as the National Physical Laboratory (NPL) in the UK and Physikalisch-Technische Bundesanstalt (PTB) in Germany, to maintain global measurement consistency.

While NIST traceability rigorously documents the calibration process, it does not extend to laboratory management protocols. For example, it does not cover quality manuals, risk mitigation strategies, or broader management systems. As NIST notes:

"traceability alone does not signify or guarantee fitness for purpose, because this typically requires that the uncertainty associated with a measured value or calibration be sufficiently small to satisfy a particular measurement need".

Responsibility for proving traceability lies with the measurement provider. According to NIST:

"providing support for a claim of metrological traceability of a measurement result is the responsibility of the provider of that result... and assessing the validity of such a claim is the responsibility of the user".

In practice, this means you cannot simply cite a NIST test number as evidence of traceability. Instead, you must thoroughly document your entire measurement system. This includes every calibration step, the associated uncertainties, and the dates when standards were last verified.

sbb-itb-501186b

ANSI Z540 vs. NIST: Main Differences

Let’s break down the main differences between ANSI Z540 and NIST, building on the earlier discussion of their roles and requirements. At their core, the distinction lies in their purpose and function. NIST serves as a federal agency and the National Measurement Institute for the United States, responsible for establishing national measurement standards and SI unit realizations. On the other hand, ANSI Z540 (including Z540-1 and Z540.3) is a set of documentary standards that define requirements for calibration labs and the management of measuring and test equipment.

NIST focuses on defining the measurement standards, while ANSI Z540 outlines the procedures for calibration laboratories. According to NIST:

"Metrological traceability requires the establishment of an unbroken chain of calibrations to specified reference standards: typically national or international standards".

ANSI Z540 complements this by specifying requirements like the 4:1 Test Uncertainty Ratio (TUR) in Z540-1 and risk management protocols in Z540.3, ensuring labs follow structured processes when maintaining traceability.

The two frameworks differ significantly in their scope. NIST traceability centers on the accuracy lineage of measurements, ensuring each result is tied back to national standards with documented uncertainty calculations. Meanwhile, ANSI Z540 takes a broader view, addressing laboratory management systems, quality manuals, annual audits, and equipment control procedures. As NIST explains:

"traceability alone does not signify or guarantee fitness for purpose, because this typically requires that the uncertainty associated with a measured value or calibration be sufficiently small to satisfy a particular measurement need".

Despite being withdrawn by NCSL International, Z540-1 and Z540.3 are still legally valid and widely used in contracts. They often act as supplements to ISO/IEC 17025:2017. For instance, agencies like the U.S. Navy and NASA continue to require ANSI Z540.3 subclause 5.3 for managing high-level calibration risks.

The comparison table below highlights the key differences between ANSI Z540 and NIST, helping to clarify which framework applies best to specific calibration needs.

Comparison Table: ANSI Z540 vs. NIST

| Feature | NIST | ANSI Z540 |

|---|---|---|

| Nature | Federal agency and National Measurement Institute | Documentary standards for laboratory accreditation |

| Primary Scope | Maintains SI unit realizations; provides foundation for U.S. measurements | Establishes requirements for lab management and M&TE control |

| Traceability Role | Provides the source of traceability; top of the unbroken chain | Requires labs to document and maintain chain to NIST or other NMIs |

| Key Requirements | Unbroken calibration chain with documented uncertainty | 4:1 TUR (Z540-1) or Probability of False Acceptance limits (Z540.3) |

| Audit Requirements | Operates under NIST Quality System for Measurement Services | Mandates annual quality system reviews and procedure audits |

| Risk Management | Emphasizes traceability doesn't guarantee fitness for purpose | Mandates specific uncertainty ratios or PFA calculations |

| Typical Applications | Universal foundation for measurement science | Defense, aerospace, government contracting |

| Standard Status | Active federal agency | Withdrawn but legally valid for contracts |

When to Use ANSI Z540 or NIST

Opt for ANSI Z540 when dealing with high-stakes projects where even minor measurement errors could lead to safety risks or significant financial losses. This rigorous standard is essential for critical sectors like aerospace, military, nuclear power, and medical instrumentation. It enforces a strict 4:1 ratio to ensure that measurement uncertainty stays below 25% of the tolerance.

For lower-risk situations where measurements only need to be "close enough", NIST traceability is usually sufficient. Steve Keithley from Mensor explains:

"If the device is used more for reference purposes in a low risk setting in which the measurement just needs to be 'close enough,' a NIST traceable calibration is most likely all that is required".

Examples where NIST traceability works well include tire pressure gauges, torque wrenches in auto shops, and general process indicators.

In industries like defense and aerospace, contractual requirements often mandate ANSI Z540 compliance. This standard provides additional liability protection for critical applications. Even though Z540-1 was withdrawn in 2007, it remains a staple in Department of Defense and aerospace contracts, particularly for legacy programs like Navy nuclear components. Keithley adds:

"If the equipment is being used in a critical application and there could be some risk of liability to the company if something were to go wrong, an ISO/IEC 17025 calibration might be worth considering".

While NIST traceability confirms an unbroken chain of measurement, ANSI Z540 accreditation goes further by verifying a laboratory's technical expertise and adherence to strict quality-control systems. These principles are especially crucial for addressing the demands of electrical test instruments.

Electrical Equipment Calibration Applications

When it comes to electrical calibration, the choice between ANSI Z540 and NIST depends on the complexity and criticality of the application. For specialized instruments like Frequency Response Analyzers, meeting ANSI Z540.1 standards may require hardware or firmware updates. For example, Venable Instruments has highlighted that its 6300 and 7400 series analyzers need phase accuracy adjustments to comply with Z540.1 requirements for aerospace applications. On the other hand, NIST traceability is often sufficient for routine maintenance calibrations.

NIST also provides Standard Reference Instruments (SRIs) for electrical applications, such as voltage standards. For power distribution equipment like transformers or breakers - such as those available through Electrical Trader (https://electricaltrader.com) - the calibration standard depends on the equipment's use. Critical infrastructure often requires ANSI Z540 compliance, while general maintenance equipment can rely on NIST traceability. Transfer standards calibrated by NIST serve as a vital link between national measurement benchmarks and precision electrical tools used in the field.

Choosing the Right Standard

Take a close look at your contractual obligations. Even though ANSI Z540.1 and ANSI Z540.3 have been officially withdrawn, they are still valid and can be specified in contracts if needed. If you’re working with government agencies like the U.S. Navy or NASA, check whether your calibration provider needs to comply with ANSI Z540.3 subclause 5.3.

ANSI Z540.3 is best suited for applications that demand strict measurement assurance and Probability of False Acceptance (PFA) calculations. However, it’s important to note that traceability alone isn’t enough to ensure a measurement meets its intended purpose. As NIST explains:

"Traceability alone does not signify or guarantee fitness for purpose, because this typically requires that the uncertainty associated with a measured value or calibration be sufficiently small to satisfy a particular measurement need".

If you’re opting for ANSI Z540.1, ensure the calibration lab adheres to the 4:1 Test Uncertainty Ratio (TUR) requirement. If the lab cannot maintain this ratio, it must provide documented approval for any deviations. This step is crucial for meeting contractual standards and maintaining reliable operational performance.

Additionally, ensure that every measurement has an unbroken traceability chain with documented uncertainty. Calibration providers are responsible for supporting any claims of traceability.

For critical infrastructure like power distribution equipment and components, ANSI Z540 is the go-to standard. For general maintenance, NIST traceability is sufficient. To simplify compliance, use the ANSI Z540-1 accreditation checklist (CL 2983). Ultimately, align your choice of standard with the specific calibration needs of your electrical equipment to ensure precise and reliable measurements for your critical applications.

FAQs

What are the key differences between ANSI Z540 and NIST standards?

The key distinction lies in their focus and application. ANSI Z540 is a voluntary standard in the U.S., tailored specifically for calibration and testing laboratories. It emphasizes quality system requirements and practices to ensure accurate calibration processes. On the other hand, NIST standards operate within a government-supported framework based on ISO/IEC 17025. These standards encompass a wider array of measurement services, including calibration, reference materials, and data quality.

While industries relying on precise calibration often turn to ANSI Z540, NIST standards are designed to guarantee traceability and consistency across diverse scientific and technical fields. Both are essential for upholding accuracy and reliability in measurements, though their purposes and frameworks vary depending on the specific needs of the application.

Why is compliance with ANSI Z540 important for industries with critical operations?

Compliance with ANSI Z540 plays a crucial role in industries where precision and reliability are paramount - think aerospace, healthcare, and manufacturing. This standard sets rigorous guidelines for calibration processes, ensuring measurements are accurate, traceable, and meet both regulatory demands and customer expectations.

Following ANSI Z540 helps businesses minimize risks tied to equipment failures, streamline operations, and cut down on maintenance expenses. Beyond the technical benefits, it also strengthens trust by showcasing a dedication to quality and accountability in critical, high-pressure environments.

How does NIST maintain traceability to SI units in calibrations?

NIST ensures a direct connection to SI units by calibrating its reference standards against primary SI realizations. This process follows a clear, documented chain of calibrations, where each step accounts for and evaluates uncertainty. This approach guarantees that all measurements are reliably tied back to the original SI standards, maintaining consistency and precision in calibration practices.