Top 7 Tools for Electrical Device Calibration

Share

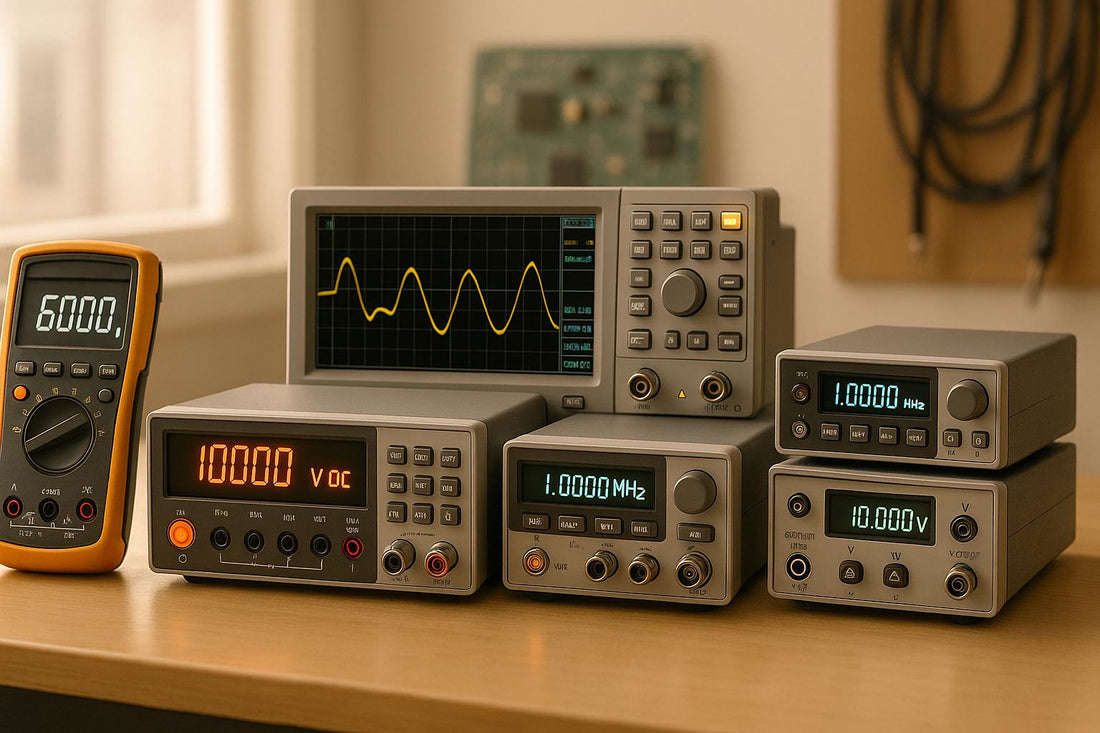

Calibrating electrical devices ensures accurate and reliable measurements, which are critical for safety, operational efficiency, and compliance with industry standards. Here's a quick overview of the top 7 tools for electrical calibration:

- Digital Multimeter Calibrators: Test and fine-tune multimeters by generating precise electrical signals.

- Multifunction Calibrators: Handle voltage, current, resistance, frequency, temperature, and pressure in one device.

- Milliamp Loop Calibrators: Essential for 4–20 mA current loops in industrial systems.

- Voltage Calibrators: Generate stable voltage signals for calibrating voltmeters and similar devices.

- Insulation Resistance Testers: Evaluate insulation quality in motors, transformers, and cables.

- Process Calibrators: Combine multiple calibration functions for field and lab use.

- Frequency Calibrators: Ensure precise frequency outputs for RF and audio systems.

Quick Comparison

| Tool | Key Features | Applications | Best For |

|---|---|---|---|

| Digital Multimeter Calibrators | Precise voltage, current, resistance signals | Multimeter calibration | Basic electrical testing |

| Multifunction Calibrators | All-in-one for multiple parameters | Lab and field calibration | Versatile calibration tasks |

| Milliamp Loop Calibrators | Measures/sources 4–20 mA current | Industrial process control | 4–20 mA systems |

| Voltage Calibrators | Stable voltage signals | Voltmeter calibration | Voltage-specific tasks |

| Insulation Resistance Testers | Insulation quality checks | Electrical safety | Insulation system testing |

| Process Calibrators | Multi-parameter calibration | Industrial manufacturing | On-site process calibration |

| Frequency Calibrators | Precise frequency signals | RF and audio systems | Frequency-specific tasks |

These tools are essential for maintaining accuracy, reducing downtime, and ensuring compliance with standards like ISO 9001 and IEC 17025. Regular calibration - every 6 to 24 months - helps prevent costly errors and extends equipment lifespan.

Tools for Instrumentation Technician

1. Digital Multimeter Calibrators

Digital multimeter calibrators play a key role in ensuring accurate measurements for various electrical devices. These tools generate precise electrical signals to test and fine-tune the performance of digital multimeters, acting as reference standards to confirm that your instruments meet required specifications.

Accuracy and Precision

When it comes to calibration, accuracy refers to the maximum allowable error, often expressed as a percentage, while precision is the ability to consistently replicate the same measurement. Even small deviations can affect reliability. For instance, Fluke handheld digital multimeters typically offer basic DC accuracy ranging from 0.5% to 0.025%. To maintain high reliability, a test uncertainty ratio (TUR) of at least 4:1 is recommended. This ensures the device’s tolerance significantly exceeds the calibration uncertainty.

Multiple Calibration Functions

Digital multimeters measure various parameters like DC/AC voltage, resistance, capacitance, and DC current. Calibrators must replicate all these functions with precision levels at least four times greater than the device being tested. This versatility allows calibrators to perform effectively in both laboratory settings and on-site environments.

Field and Bench Use Options

Calibrators come in two main types: benchtop and portable models, catering to different needs. Benchtop calibrators are better suited for labs, offering higher precision, faster readings, and advanced automation. For example, Keysight’s benchtop DMM models start with resolutions at 5.5 digits, while advanced models like the 3458A can reach up to 8.5 digits with a one-year DCV accuracy of 8 ppm. On the other hand, portable calibrators are built for rugged, off-site use and maintain reliable precision even under challenging conditions.

Application-Specific Features

Some calibrators include features like temperature compensation and external tool integration to handle temperature-sensitive measurements. High-end benchtop multimeters often require more detailed calibration procedures and tighter tolerance checks compared to portable models. Always refer to your multimeter’s manual to identify the recommended functions and minimum specifications for proper calibration. The calibration process typically involves comparing the multimeter’s readings against a reference standard that is traceable to recognized national or international benchmarks.

2. Multifunction Calibrators

Expanding on the capabilities of digital multimeter calibrators, multifunction calibrators combine several functions into a single device. These all-in-one instruments are designed to handle a variety of calibration tasks - such as voltage, current, resistance, frequency, temperature, and pressure - making them indispensable for comprehensive electrical testing.

Multiple Calibration Functions

Unlike single-function calibrators, multifunction calibrators are equipped to measure a wide range of parameters, including voltage, current, frequency, resistance, pressure, pulses, and temperature. Higher-end models go a step further, offering features like pulse sourcing, pH measurement, dual channels, and the ability to store test routines. Many also support communication protocols like HART and Profibus PA, which are essential for advanced industrial applications.

Accuracy and Precision

These devices are designed to source and measure multiple parameters with exceptional accuracy. Their precision is ensured by comparing their outputs to standards tied to national benchmarks, such as NIST in the United States, or to international standards and certified reference materials. For example, typical voltage and milliamp measurements achieve an accuracy of around 0.05%, while premium models like the Fluke 726 Precision Multifunction Calibrator can deliver an impressive accuracy of 0.01%. The resolution on these devices ranges from 0.01 V and 0.01 mA on basic models to as precise as 0.001 V and 0.001 mA on advanced versions. In industrial calibration, the standard practice is to use a calibrator with an accuracy at least four times greater than the device being tested. Additional features, such as storing frequently used test setups or programming custom RTD probe calibration constants, enhance their usability for temperature measurements.

Field and Bench Use Options

Multifunction calibrators are built for versatility, making them suitable for both fieldwork and bench testing. Portable models are particularly useful for on-site testing, minimizing equipment downtime. Using a single device to handle pressure generation, high-accuracy measurements, and device calibration is often more cost-effective than maintaining multiple specialized instruments.

Application-Specific Features

Thanks to advancements in microprocessor technology and miniaturized components, modern multifunction calibrators pack extensive capabilities into compact, handheld designs. Many models come with traceable calibration certificates to ensure accuracy and compliance with industry standards. When choosing a multifunction calibrator, it’s essential to consider the specific functions, accuracy requirements, and additional features that can streamline fieldwork and troubleshooting. Factors like the types of signals to be calibrated, measurement parameters, and the need for a calibration certificate should guide your decision.

For instance, high-precision models like the Fluke 726 Precision Multifunction Calibrator (priced at $5,394.99) and the Fluke 725 Multifunction Process Calibrator (priced at $4,042.99) are excellent for demanding applications. On the other hand, budget-friendly options like the PD9501 are available for $665.00. These integrated features make multifunction calibrators an essential tool, setting the stage for more specialized equipment discussed later in this guide.

3. Milliamp Loop Calibrators

Milliamp loop calibrators play a crucial role in electrical device calibration, particularly for 4–20 mA current loops. These loops are the backbone of industrial measurement and control systems, and calibrators ensure their accuracy by allowing technicians to read, source, and simulate milliamp signals.

The 4–20 mA standard has its roots in earlier mechanical calibration methods, specifically the 3–15 psi range, which made the transition to electronics smoother. Today, this standard is widely used because it’s simple to set up, works with a variety of power supplies, produces minimal noise, and can transmit signals over long distances without significant loss. This makes precise calibration of these loops essential for maintaining the reliability of industrial systems.

Accuracy and Precision

Milliamp loop calibrators are designed with precision in mind. For instance, the Fluke 709 Precision Loop Calibrator boasts an accuracy of 0.01% of reading, while the Omega PCL120 achieves ±0.015% accuracy with a resolution of 0.001 mA. The Fluke 705 Loop Calibrator offers a slightly lower accuracy of 0.02%. These high levels of precision are vital for ensuring that instruments interpret 4 mA and 20 mA signals accurately, corresponding to 0% and 100% levels, even when accounting for wiring runs.

Field and Bench Use Options

Milliamp loop calibrators are versatile, working well in both field and lab environments. Handheld calibrators are designed to withstand tough conditions, often featuring water and dust resistance, which makes them ideal for on-site troubleshooting. On the other hand, bench calibrators are better suited for controlled laboratory settings, where higher precision is often required.

"The Fluke 709 mA loop calibrator is designed to reduce the time it takes to measure or source voltage or current and power up a loop and still produce high-quality results".

Application-Specific Features

These calibrators come equipped with features tailored for 4–20 mA loop calibration. Many models include a 24V loop power supply, enabling them to power and test process transmitters while simultaneously measuring the 4–20 mA signals drawn by the transmitter. Additional functions like auto-step, ramp modes, and span checks make it easier to verify calibration endpoints quickly . Some models also offer selectable ramp speeds and step functions, which are particularly useful for valve testing and functional loop diagnostics, saving time and improving consistency.

For systems that use HART communication, specialized models like the Fluke 709H provide both precision mA loop calibration and HART diagnostics. The Fluke 710 goes a step further, integrating pre-configured control valve tests, HART communication, and 0.01% accuracy for mA measurement and sourcing. Wireless diagnostic models add another layer of convenience, allowing remote testing and calibration of current, voltage, and pressure devices in 4–20 mA loops. These often include built-in test procedures for HART-enabled smart control valves.

Here’s a quick comparison of some popular models:

| Model | Price | Accuracy | Resolution | HART Support |

|---|---|---|---|---|

| Fluke 709 | $1,402.99 | 0.01% of reading | 1 µA | No |

| Fluke 709H | $1,903.99 | 0.01% of reading | 1 µA | Yes |

| Fluke 705 | $1,231.99 | 0.02% | 0.001 mA | No |

| PIE 434 | $1,469.00 | High accuracy | – | Yes |

| Additel ADT210 | $1,492.00 | 0.01% RD | – | No |

When choosing a milliamp loop calibrator, it’s important to match the device’s accuracy to your specific needs. Models with higher accuracy, such as those offering 0.01% of reading, are better suited for more demanding applications. Additionally, prioritize calibrators with intuitive interfaces, like quick-set rotary knobs, to streamline the setup process .

4. Voltage Calibrators

Voltage calibrators are indispensable tools for generating stable, highly accurate voltage signals, making them vital for devices like voltmeters and oscilloscopes. These tools act as reliable benchmarks, ensuring that instruments meet their required specifications. A key principle when choosing a voltage calibrator is the "10× rule": the calibrator's precision should be ten times greater than the instrument it’s calibrating. These devices play a crucial role in setups that demand precise voltage measurements.

Accuracy and Precision

Modern voltage calibrators are designed to meet the high precision needs of industrial applications. For instance, the TI1000 Precision AC/DC Voltage Calibrator offers an accuracy of 200 ppm for AC and 100 ppm for DC. Similarly, the 1044 Voltage and Current Calibrator delivers an accuracy of 0.05% of its range. These levels of precision make such calibrators ideal for verifying the accuracy of multimeters and other electronic measuring tools.

Multiple Calibration Functions

DC voltage calibrators are versatile, providing stable and precise voltage and current outputs. They are commonly used to verify power supply outputs and simulate different operational conditions in control systems. For example, the ETX-2015 model offers a range of functions with impressive accuracy:

| Function | Range | Accuracy |

|---|---|---|

| DC Voltage Source | 0–10 V | 0.02% TYP |

| DC mV Source | 0–100 mV | 0.02% TYP |

| DC Voltage Measurement | 0–30 V | 0.02% TYP |

| DC mV Measurement | 0–100 mV | 0.02% TYP |

| Frequency Source | 0.00 Hz–20.000 kHz | 0.02% TYP |

Field and Bench Use Options

Voltage calibrators are available in both portable and bench configurations, catering to different working environments. For example, the PD9501 Multi-Function Calibrator is a flexible option, capable of measuring and sourcing voltages ranging from 0–30 V, 0–25 mV, and 0–100 mV. Portable models like the ETX-2015 are designed for durability, featuring IP67 waterproofing for fieldwork. On the other hand, bench models are better suited for laboratory use, offering greater stability and broader measurement ranges.

Application-Specific Features

Advanced voltage calibrators come equipped with features tailored to specific calibration challenges. Process voltage calibrators, for instance, are designed to source and measure DC voltage, making them ideal for checking meters, transducers, power supplies, and analog outputs. High-end models, such as the TI1000 series, include programmable calibration capabilities and multiple interfaces for efficient data transfer. The TI1000-B version handles frequencies from DC to 2 kHz, while the TI1000-C extends the range up to 20 kHz.

When selecting a voltage calibrator, it’s essential to evaluate factors like accuracy, calibration range, traceability, ease of operation, and budget. Options range from the cost-effective ETX-2015 at $295.50 to premium models like the 1044 Voltage and Current Calibrator, priced at $1,075.00, which provides a broader range and higher precision.

sbb-itb-501186b

5. Insulation Resistance Testers

Ensuring insulation integrity is a cornerstone of electrical safety. Insulation resistance testers play a key role in this by evaluating the quality of insulation in motors, transformers, switchgear, cables, and other electrical installations. These devices measure insulation resistance directly, helping to identify potential issues before they escalate into electrical faults or safety risks. Regular insulation testing is a critical part of any comprehensive calibration routine for electrical systems.

Accuracy and Precision

Modern insulation resistance testers are designed to deliver the precision needed for dependable safety assessments. For instance, the Time Electronics 5068 Insulation Tester Calibrator boasts an impressive 1% accuracy for resistance settings and ensures 1% reading accuracy for voltage and current measurements.

"Know the accuracy of your insulation testers and megohmmeters. Transcat's accredited insulation tester calibrations can provide the critical confirmation that your instruments meet quality and safety standards." – Transcat

These testers typically operate across a wide range, from megohms (MΩ) to gigohms (GΩ). Routine calibration is essential to maintain the reliability of these critical measurements, whether you're working in the field or a controlled lab environment.

Field and Bench Use Options

Insulation resistance testers are versatile, catering to both portable fieldwork and bench applications. Take the Fluke 1507 Insulation Resistance Tester, for example. Weighing only 1.2 pounds and measuring a compact 1.97 x 3.94 x 8.00 inches, it’s ideal for on-site tasks. Features like remote probes for hard-to-reach areas and magnetic hanging systems enhance efficiency during field operations.

"Rugged, compact advanced insulation resistance tester for electrical contractors and industrial and commercial electricians" – Fluke

Priced at $856.99, the Fluke 1507 enjoys a 4.7 out of 5 rating from 20 users, who praise its durability and reliable performance.

Application-Specific Features

Insulation resistance testers are equipped with features tailored to meet the demands of various electrical systems. For instance, the Fluke 1507 offers selectable test voltages ranging from 50V to 1000V and a fixed 1mA current output, enabling technicians to fine-tune settings for specific equipment.

Temperature compensation is another crucial feature. Since insulation resistance can double with every 18°F (10°C) temperature change, testers adjust readings to standard reference points like 68°F (20°C) or 104°F (40°C). In Singapore’s utility sector, the Fluke 1587 Insulation Multimeter is often used for tasks such as insulation resistance verification, continuity checks, and voltage measurements on transmission cables. These capabilities not only enhance safety but also ensure measurement accuracy, underscoring the importance of periodic calibration.

Industry standards recommend annual calibration of insulation resistance testers to maintain the accuracy of safety-critical measurements throughout their operational lifespan.

6. Process Calibrators

Process calibrators are indispensable tools for testing and calibrating industrial process equipment right on-site. These handheld, battery-powered devices are designed to measure and source electrical parameters like voltage, loop current, and temperature signals with precision. By combining multiple functions into one portable instrument, process calibrators simplify the calibration process, making them a go-to choice in manufacturing environments. Choosing the right one often comes down to finding the balance between functionality, accuracy, and ease of use.

Multiple Calibration Functions

Today’s process calibrators pack a lot into a small package. They typically handle voltage, loop, and temperature calibration, but advanced models go further. Some include capabilities for frequency and pulse measurements, pH sourcing, pressure measurement, or even dual-channel operation. Brands like WIKA and SIKA offer models that integrate all these features, providing a comprehensive solution for various calibration needs. For specific tasks like troubleshooting 4–20 mA current loops, specialized loop calibrators are particularly effective.

Accuracy and Precision

One standout feature of process calibrators is their exceptional precision. Many models boast accuracies as tight as 0.05% for voltage and milliamp measurements. Take the Fluke 726 Precision Multifunction Process Calibrator, for instance - it delivers an impressive accuracy of 0.01% and enjoys strong user reviews, with a 4.6 out of 5-star rating on Amazon. This high level of precision is achieved by using internal standards that exceed the accuracy of the devices being tested. Temperature calibration is also critical, as temperature sensors often account for more than 75% of errors in temperature transmitters. Accurate calibration ensures product quality remains consistent, making these tools invaluable in industrial settings.

Field and Bench Use Options

Process calibrators are designed for versatility, whether you’re working in the field or at a bench. In the field, they enable on-site verification without the hassle of removing equipment. Portable models, especially those built to be intrinsically safe, perform well even in tight or hazardous spaces. On the other hand, bench calibration in controlled environments allows for more detailed inspections with the help of external utilities.

Application-Specific Features

Many process calibrators come with features tailored to specific applications. For example, models with intrinsic safety are ideal for explosive environments, while others offer automatic data logging and test routine storage. These features help reduce downtime and ensure consistent quality during testing and troubleshooting.

Ultimately, selecting the right process calibrator comes down to understanding your specific needs - whether it’s advanced functionality, a high degree of accuracy, or features that make fieldwork more efficient.

7. Frequency Calibrators

After exploring tools for voltage and current calibration, let's dive into frequency calibrators - devices built specifically to tackle the challenges of frequency accuracy. These instruments generate precise frequency signals, ensuring the reliability of equipment that depends on specific frequency outputs, like audio gear and RF communication systems. Unlike general-purpose calibrators, frequency calibrators are all about delivering stable, accurate frequency signals, which are critical for precise measurements in various applications.

Accuracy and Precision

The performance of a frequency calibrator hinges on two key aspects: accuracy - how close the generated frequency is to the intended value - and precision - how consistently it produces that value. For instance, a typical reference oscillator may age at a rate of 0.152 parts-per-million (ppm) annually. This means a 1 GHz source could drift by about ±152 Hz over the course of a year. Regular calibration is essential to keep such drift in check.

Modern frequency calibrators have significantly improved accuracy. Take RF Explorer signal generators with TCXO technology as an example - they achieve an accuracy of 0.5 ppm, reducing initial tolerances from ±100 ppm to ±10 ppm or better after calibration. Additionally, resolution - defined as the frequency span divided by the number of available sweep steps - plays a crucial role in ensuring precise measurements.

Field and Bench Use Options

Frequency calibrators are versatile, serving both field and laboratory settings. Field models are designed with portability and durability in mind. For instance, the Brightwin ETX-2015 frequency calibrator, priced at $295.50, is a rugged, handheld device that delivers accurate frequency outputs even in challenging conditions.

On the other hand, bench models focus on higher accuracy and broader functionality, though they’re less portable. A good example is the Fluke 726 Precision Multifunction Calibrator, which comes with a price tag of $5,610.99 and offers advanced features tailored for laboratory use.

Application-Specific Features

Frequency calibrators often include features tailored to meet the demands of specific industries. For example, audio engineers typically work within a frequency range of 20 Hz to 20 kHz, while RF engineers require a much broader range, spanning from 3 kHz to 300 GHz. Microwave applications might even call for frequencies exceeding 1 GHz, reaching up to 30 GHz.

Resolution needs also vary. Low-frequency audio signals may demand a fine resolution of 0.01 Hz to detect subtle variations, whereas high-frequency RF signals can often be monitored effectively with a resolution of 1 Hz or better.

Another critical factor is input sensitivity, especially for measuring weak signals in telecommunications and RF testing. The calibrator must capture these low-power signals accurately without introducing noise or distortion. Compatibility with signal inputs is equally important. Analog inputs work well for continuous signals, such as those in RF testing and audio systems, while digital inputs are ideal for discrete signals often found in telecommunications and computing applications. Additionally, environmental factors like temperature, humidity, and vibration can influence performance, so a robust design is essential for consistent results.

When choosing a frequency calibrator, consider the frequency range required for your application, ensure the resolution is fine enough to detect small variations, and verify that the device can handle weak signal measurements with sufficient sensitivity.

Tool Comparison Chart

Choosing the right calibration tool comes down to your specific needs, budget, and work environment. The chart below highlights seven essential calibration tools, making it easier to compare their features and applications.

| Tool | Key Features | Typical Applications | Best For |

|---|---|---|---|

| Digital Multimeter Calibrators | Deliver precise voltage, current, resistance, and frequency signals | Calibrating digital multimeters and basic electrical measurements | Basic electrical testing and meter calibration |

| Multifunction Calibrators | Source and measure voltage, current, frequency, and resistance; handle multiple instrument types | Calibrating electrical equipment, pressure sensors, thermocouples, RTDs, and pH sensors | Versatile lab and field work |

| Milliamp Loop Calibrators | Measure and source 4–20 mA current; simulate loop-powered transmitters | Industrial process control and current loop troubleshooting | Process industries using 4–20 mA systems |

| Voltage Calibrators | Generate stable and precise voltage signals | Calibrating voltmeters and voltage measuring devices | Dedicated voltage measurement tasks |

| Insulation Resistance Testers | Measure resistance for insulation testing | Calibrating insulation testers and safety equipment | Electrical safety and insulation checks |

| Process Calibrators | Calibrate pressure, temperature, and flow parameters | Used in food, beverage, chemical, pharmaceutical, and petroleum industries | Industrial process control and manufacturing |

| Frequency Calibrators | Produce stable and highly accurate frequency signals | Calibrating frequency counters and tachometers | Precise frequency measurement needs |

While the chart provides a quick overview, selecting the right tool often requires deeper consideration of factors like your equipment's signal types, accuracy requirements, and whether you need a portable or bench unit. Below are some examples and considerations to guide your decision.

For instance, the Fluke 726 Precision Multifunction Calibrator, priced at $5,610.99, offers top-tier performance for demanding tasks, while the Brightwin ETX-2015, at just $295.50, provides a budget-friendly alternative. If portability is a priority, the Fluke 787 ProcessMeter at $759.99 is an excellent choice for on-site work. On the other hand, bench units like the Time Electronics 1010 DC Voltage Calibrator, priced at $2,200.00, excel in delivering stability for laboratory conditions.

Higher-priced calibrators generally offer better accuracy and stability, making them ideal for critical applications. For example, the Fluke 789 ProcessMeter, with a 4.6-star rating on Amazon, includes a built-in 24V loop supply, making it a standout for comprehensive process tasks. For specialized applications, such as valve testing, the 710 mA Loop Valve Tester is equipped with advanced features.

"In short, if measurement results matter, calibration matters." - Jeff Gust, Chief Corporate Metrologist of Fluke Corporation

Conclusion

Having the right calibration tools is key to ensuring precise and reliable performance across various applications. Mike Imholte, Sr. Calibration Technician at Boston Scientific, highlights this importance:

"When you realize a pacemaker goes inside a person's chest and connects directly to the heart, it's easier to understand why a properly working and reliable pacemaker requires many precise measurements and tests. And to make sure our testing devices and manufacturing equipment is producing within very tight measurement tolerances, we regularly calibrate them with the best quality calibrators. Given the criticality of meeting specifications, we need to have the assurance that calibration provides throughout the entire manufacturing process. This is why calibration is necessary."

The stakes go beyond safety. Poor calibration can lead to expensive manufacturing defects, product recalls, and even safety hazards. To avoid these risks, it’s recommended that electronic test instruments undergo regular calibration - ideally at least once a year.

Well-maintained instruments not only ensure accuracy but also improve operational efficiency, reduce maintenance needs, extend equipment lifespan, and provide dependable data. In systems where precision is non-negotiable - like those involving sensors, controllers, and electrical components - calibration becomes the backbone of both operational success and regulatory compliance. By choosing high-quality calibration tools, you protect your processes and maintain alignment with industry requirements.

For dependable calibration tools and electrical components, Electrical Trader offers a wide selection of instruments. Whether you need digital multimeter calibrators for everyday tasks or advanced multifunction calibrators for specialized lab work, having access to reliable equipment ensures your measurements are accurate and your operations remain compliant.

Calibration isn’t just about meeting technical specifications - it’s about safeguarding safety, maintaining quality, and protecting your bottom line.

FAQs

How often should I calibrate my electrical devices to maintain accuracy and meet industry standards?

Most electrical devices need to be calibrated once a year to maintain their accuracy and meet industry standards. However, for equipment that's critical or operates in tough conditions, calibration might be necessary every six months or even every three months.

The right calibration schedule depends on several factors, including how often the device is used, the conditions it operates under, and any relevant industry rules. It's always a good idea to check the manufacturer’s recommendations or seek advice from a professional to figure out the most suitable calibration frequency for your equipment.

What should I consider when deciding between a benchtop and portable calibrator for fieldwork?

When deciding between a benchtop calibrator and a portable calibrator, it's important to weigh factors like precision, mobility, and the conditions in which you'll be working. Benchtop calibrators shine in controlled environments, offering superior accuracy and advanced capabilities, making them ideal for laboratory settings where stability is a priority.

In contrast, portable calibrators are built for flexibility. They’re a go-to choice for fieldwork or scenarios where moving between locations is a must.

Ultimately, your choice should depend on your specific needs. If you're focused on convenience and mobility, a portable option might be the best fit. But if your work demands top-tier precision and advanced features, a benchtop calibrator could be the better solution.

Why should a calibrator be more accurate than the device being tested, and what impact does this have on the calibration process?

Using a calibrator that offers greater precision than the device being tested is crucial for achieving reliable and accurate measurements. This approach minimizes the chances of calibration errors and helps preserve the device's overall performance.

Highly precise calibrators are capable of detecting even minor deviations caused by factors like wear and tear, environmental fluctuations, or the natural aging of equipment. Addressing these small discrepancies not only boosts the device's measurement accuracy but also enhances safety and ensures consistent quality in the products or processes it supports over time.

Related posts

- Electrical Equipment Inspection Checklist

- Electrical Safety Questions Every Pro Should Know

- Humidity's Role in Calibration Errors

- IEC Standards for RCDs: Overview