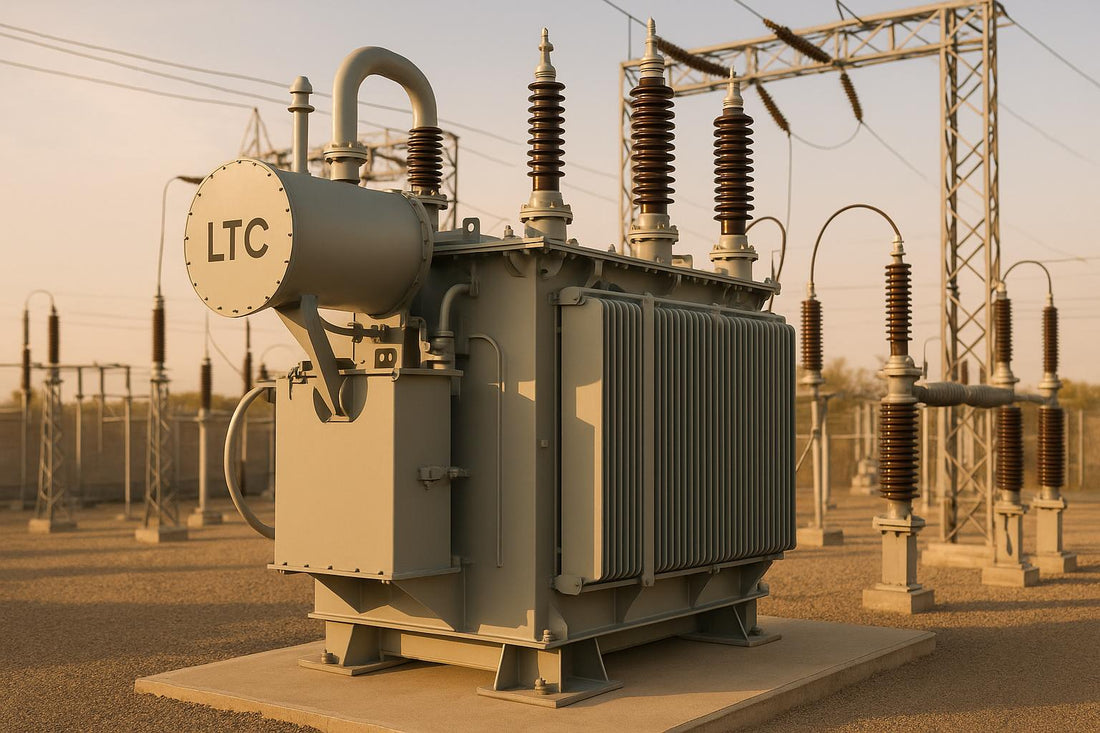

LTCs for Power Transformers

Share

Load Tap Changers (LTCs) are critical for regulating voltage in power transformers, ensuring stable electricity distribution. They adjust the transformer's winding connections to control the output voltage, enhancing efficiency and reducing energy losses in power systems. LTCs are categorized into two types:

- On-Load Tap Changers (OLTCs): Adjust voltage without interrupting power flow, ideal for systems with fluctuating loads.

- Off-Load Tap Changers (NLTCs): Require the transformer to be de-energized for adjustments, suitable for stable load conditions.

Key Facts:

- OLTCs are more complex and require frequent maintenance but allow continuous operation.

- NLTCs are simpler, cost less initially, and need minimal upkeep but require downtime for adjustments.

- LTCs typically regulate voltage within a ±10% range, with precise increments (e.g., 0.625%).

Proper maintenance, including inspections, oil analysis, and contact replacement, is essential to prevent failures and extend LTC lifespan. Selecting the right LTC depends on factors like load variability, transformer type, and operating conditions (e.g., temperature, humidity, altitude).

Ultimately, LTCs are indispensable for consistent voltage regulation in applications ranging from power grids to renewable energy systems, ensuring reliable and efficient electricity distribution.

Transformer Off Circuit and On Load Tap Changer function, components, installation, operation part1

Types of Load Tap Changers: On-Load vs. Off-Load

Load tap changers are categorized into two main types: on-load tap changers (OLTCs) and off-load tap changers (NLTCs). Choosing the right type depends on the specific needs of your transformer application. Below, we break down how these two types operate and their key characteristics.

On-Load Tap Changers (OLTCs)

OLTCs are designed to adjust voltage without interrupting the transformer's operation. This means the transformer can stay energized and continue supplying power even as voltage adjustments are made. This feature makes OLTCs ideal for situations where continuous operation is critical, such as in power distribution systems that experience fluctuating load conditions throughout the day.

These tap changers are widely used in electrical networks and industries where downtime is not an option. For example, phase-shifting transformers (PSTs) often rely on OLTCs because they handle frequent operations and offer a broad range of voltage regulation. In fact, OLTCs in PSTs typically perform 10 to 15 times more operations than those in other types of regulating transformers.

Off-Load Tap Changers (NLTCs)

NLTCs, on the other hand, require the transformer to be powered down before any voltage adjustments can be made. Adjustments are usually done manually, which makes them more suited for applications with stable load conditions where voltage changes are infrequent.

The simplicity of the NLTC design - primarily manual switching components - results in lower initial costs and reduced complexity. However, the need to de-energize the transformer during adjustments can be a drawback in scenarios requiring uninterrupted power supply.

On-Load vs. Off-Load LTC Comparison

| Feature | On-Load Tap Changer (OLTC) | Off-Load Tap Changer (NLTC) |

|---|---|---|

| Operation | Adjusts voltage while energized | Requires de-energization for changes |

| Complexity | Complex mechanisms for load current | Simple manual switching design |

| Maintenance | Regular maintenance needed | Minimal maintenance required |

| Cost | Higher initial investment | Lower initial cost |

| Voltage Regulation | Fine-grained adjustments | Limited control with fewer taps |

| Advantages | Continuous operation | Cost-effective and simple |

| Disadvantages | High cost and frequent maintenance | Downtime required for adjustments |

Maintenance needs also differ significantly between the two types. OLTCs, due to their moving parts and operation under load, are prone to mechanical wear and electrical stress. They also accumulate contaminants from insulation breakdown over time, requiring regular upkeep. Some companies report performing over 6,000 OLTC maintenance operations annually.

In contrast, NLTCs have fewer moving parts and experience less electrical stress, which simplifies their maintenance. However, the need to shut down the transformer for tap changes can be a disadvantage in applications where uninterrupted power is essential. These factors play a significant role in determining overall transformer performance and operational costs.

How Load Tap Changers Work

Grasping the basics of load tap changers (LTCs) is essential when selecting the right one for specific transformer applications. These devices adjust the transformer turns ratio to keep voltage levels steady in power distribution systems. By shifting between transformer winding taps, LTCs can either raise or lower the voltage as needed. What makes them especially useful is their ability to regulate the voltage ratio without interrupting the flow of load current.

LTC Operation Process

The operation of an LTC involves altering the number of turns in the winding to meet the desired voltage level. This adjustment typically allows for a voltage change of about ±10% from the transformer's nominal rating.

For instance, consider a 100,000 V transformer. If it moves three taps up, the voltage increases by 1.875%, resulting in 101,875 V. This is calculated as 100,000 V + (100,000 V × 0.625% × 3).

A key distinction between on-load and off-load tap changers lies in how they handle the switching process. On-load tap changers use a "make-before-break" contact method, ensuring smooth transitions between tap positions without disrupting the current flow.

The main components of an on-load tap changer include the tap selector, diverter switch, transition resistor or reactor, and a control system. To avoid issues during the switching process, two approaches are commonly used: resistive switching and reactive switching. Resistive switching employs resistors capable of handling the full load current along with the circulating current. Reactive switching, on the other hand, uses reactors that rely on reactive energy, which generates less heat during operation.

Manual vs. Automatic Control Systems

Control systems play a critical role in defining the performance of LTCs by determining how tap changes are executed. Manual tap changers require the transformer to be de-energized before adjusting the turns ratio. This makes them a good fit for applications with stable load conditions where voltage adjustments are rare.

Automatic tap changers, however, are designed for on-load systems and can adjust the turns ratio while the transformer is in operation. Most LTCs rely on a motor-driven mechanism for automatic operation, though manual operation is often available as a backup in case the motor fails. A typical 32-step LTC includes 16 raise positions and 16 lower positions.

Automatic systems are typically installed on the higher voltage (lower current) winding. This placement makes them easier to access and reduces the current load during operation. These systems continuously monitor voltage levels and make real-time adjustments to maintain stability. While manual systems are simpler, less expensive, and easier to maintain (though they require downtime for adjustments), automatic systems excel in dynamic environments. They minimize voltage fluctuations and adjust voltage levels while the system remains energized, making them ideal for applications with variable loads.

LTC Maintenance Requirements and Best Practices

Keeping load tap changers (LTCs) in good working condition is essential for grid stability and avoiding unexpected failures that could lead to costly downtime or repairs. When handled by skilled professionals, LTC maintenance typically takes just a few hours. The frequency of maintenance depends on factors like the type of LTC, its rated through-current, operational experience, and local conditions. According to UTB Transformers, neglecting regular LTC maintenance can reduce voltage control, increase operating costs, and damage equipment. They recommend a combination of routine inspections, oil sampling and analysis, contact replacement, lubrication of mechanical components, and testing and calibration to extend the lifespan of LTCs and prevent disruptions. Below are the key maintenance tasks necessary for ensuring LTC reliability.

Required Maintenance Tasks

Regular inspections and cleaning are a must. This involves examining and cleaning contacts, lubricating moving parts, and checking gasket integrity to prevent wear, arcing, and moisture intrusion. Worn contacts should be replaced immediately to avoid system failures, and any carbon buildup must be removed to maintain optimal electrical connections.

Oil sampling and analysis are critical for assessing the LTC's internal condition. Testing for moisture levels, dielectric strength, and particle contamination can identify potential issues early, helping to prevent significant damage.

When replacing contacts, it’s crucial to use manufacturer-approved parts and ensure proper alignment to avoid uneven wear and early failure.

Routine testing and calibration also play an important role. Functional tests verify that tap changes occur correctly across all positions, ensuring the LTC continues to meet voltage regulation needs.

Common Failure Modes and Prevention

Beyond routine maintenance, understanding common failure modes can help address issues before they escalate. Proactive measures significantly reduce failure rates.

Because LTCs involve moving parts operating under load, they are prone to mechanical wear, electrical stress, and contamination from insulation breakdown byproducts. Onsite diagnostics can predict up to 30% of failures, while online monitoring can catch up to 40% early.

Contact wear is one of the most frequent issues, caused by repeated switching operations under electrical load. Regular inspections can identify wear patterns before they lead to complete failure.

Damaged gaskets can allow moisture to infiltrate, leading to insulation breakdown. Routine gasket checks and timely replacement of damaged seals are essential. Mechanical binding may also occur if lubrication is insufficient or contaminants interfere with moving components.

Oil contamination negatively impacts both electrical and mechanical performance. Predictive tools like dissolved gas analysis (DGA) and infrared thermography provide early warnings of potential problems.

Maintaining detailed records of inspections, tests, and repairs is another key strategy. These logs help maintenance teams spot trends and schedule component replacements at the right time, reducing the risk of downtime.

In regions with tropical or subtropical climates, high humidity levels should be taken into account during maintenance. Humidity can skew oil analysis results and complicate electrical testing.

Finally, having qualified technicians who understand the intricacies of LTC systems is non-negotiable. Proper training ensures maintenance tasks are carried out safely and effectively, protecting both the equipment and personnel. Combining regular maintenance with early diagnostics helps maintain system reliability and minimizes operational interruptions.

sbb-itb-501186b

Selecting the Right LTC for Your Transformer Application

Choosing the right load tap changer (LTC) is critical for maintaining efficient voltage regulation and avoiding costly issues like increased maintenance or premature failure. A thorough understanding of your application's demands is key to ensuring both performance and long-term reliability. Let's break down the main criteria and environmental factors to consider when selecting an LTC.

LTC Selection Criteria

The power requirements and voltage class of your system are the first things to evaluate. The LTC's current rating must align with your transformer's capacity and be capable of handling the expected load. Typically, an LTC can regulate output voltage within ±10% of the rated voltage.

Load characteristics are equally important. Whether your system experiences steady loads, frequent fluctuations, or sudden changes, the LTC's speed and frequency of tap adjustments should match your load profile. Systems with highly variable loads may require more durable switching mechanisms and advanced control systems.

The type of transformer and its installation location will help determine whether you need an on-load or off-load tap changer. For example, distribution transformers often use fixed taps for voltage adjustments (±10%), while utility applications demand continuous voltage regulation.

Compliance with U.S. standards ensures safety and compatibility. Standards like IEEE C57, NEMA, and ANSI set stringent benchmarks for transformer design, testing, and performance, which are vital for ensuring reliability.

Finally, cost considerations go beyond the initial purchase price. Installation, operation, and maintenance expenses should also factor into your decision. While advanced LTC systems may require a higher upfront investment, they often deliver better efficiency and lower maintenance costs over time.

If your transformer operates in a parallel configuration, ensure compatibility across voltage ratios, tapping points, vector diagrams, and impedance angles. This prevents circulating currents and ensures proper load sharing.

Environmental and Operating Factors

Technical specifications alone don’t tell the whole story. Environmental conditions and operational demands can significantly influence LTC performance and longevity.

Temperature is a major factor, particularly in hot climates. High ambient temperatures or proximity to heat sources can hinder a transformer's ability to dissipate heat, affecting LTC operation. In such cases, forced cooling systems or transformers rated for higher temperatures are recommended. Temperature monitoring systems can also help identify early overheating issues.

Humidity and moisture control are crucial in damp environments. Excess moisture can degrade transformer oil, reduce its dielectric strength, and accelerate insulation aging. Without proper measures, such as a silica gel breather, air ingress can worsen humidity levels. Using an automatic regenerating dehydrating silica gel breather and regularly testing oil and insulation quality can help mitigate these risks.

Altitude affects cooling and insulation at higher elevations due to reduced air density. Transformers and LTCs rated for high altitudes or designed with enhanced insulation levels are essential in these scenarios.

In corrosive environments, like coastal areas or industrial zones, additional protection is necessary. Protective coatings, anti-corrosive materials, and specialized enclosures can shield transformers and LTCs from damage caused by salt or chemicals.

Operational stress factors, such as magnetizing inrush currents, can place significant strain on LTC components. These currents can peak at up to 30 times the full load current during energization. Ensuring transformers operate within their rated capacity can help reduce this stress.

LTCs also experience wear due to their many moving parts. Continuous operation can lead to failures that may take the entire transformer offline, disrupting distribution circuits. Choosing an LTC suited to your operational and environmental conditions minimizes these risks and ties directly to the maintenance strategies discussed earlier.

For the best results, consult with a qualified engineer or transformer manufacturer. Discussing whether your application will require voltage taps during the selection process can help avoid costly modifications down the line.

LTC Applications and Sourcing Options

Load tap changers (LTCs) play a critical role in ensuring voltage regulation and maintaining power quality across a range of industrial and utility settings. Knowing how these devices are applied and where to source dependable options is essential for achieving precise transformer control.

LTC Application Examples

Power Grid Stabilization

In the United States, utility companies depend on LTCs to stabilize voltage levels across transmission and distribution networks, particularly during peak demand periods. These devices are vital for keeping the power grid running efficiently and reliably.

Industrial Manufacturing

Industrial facilities with voltage-sensitive equipment rely on LTCs to regulate voltage consistently. For example, in one case, an on-load tap changer (OLTC) was found operating at a temperature 34°F higher than the main transformer tank. A Dissolved Gas Analysis revealed elevated ethylene and acetylene levels, and further inspection uncovered contact coking and a misaligned reversing switch. Left unaddressed, this issue could have led to a costly equipment outage.

Phase-Shifting Transformers (PSTs)

LTCs are essential components in phase-shifting transformers, where they manage power flow along transmission lines in complex, interconnected networks. This precise regulation prevents overloading and enhances overall system stability.

Renewable Energy Integration

As solar and wind energy installations grow, LTCs have become increasingly important for managing the voltage fluctuations caused by the intermittent nature of renewable power sources. By balancing these variations, they ensure that end users receive consistent, high-quality electricity.

Urban Distribution Systems

Urban areas face constantly shifting load demands, from residential air conditioning peaks to industrial operations. In these environments, LTCs automatically adjust voltage levels throughout the day to meet changing needs.

Oil-type OLTCs can switch in just 40–60 milliseconds, while resistor vacuum-type designs are capable of completing up to 300,000 cycles before requiring maintenance. With such diverse applications, choosing high-quality LTCs is critical to maintaining system reliability.

Sourcing LTCs via Electrical Trader

Given the importance of dependable LTC performance, sourcing the right equipment is a key factor in sustaining effective transformer operations. Electrical Trader offers a broad selection of new and pre-owned LTCs. Their inventory includes transformers with integrated tap changers as well as standalone LTC units, featuring specifications such as step voltage, current rating, OLTC class, poles, and insulation levels.

For those in the market for new equipment, options vary by manufacturer and design specifications. Meanwhile, pre-owned and refurbished LTCs are also available. These units undergo rigorous testing and refurbishment processes, providing a cost-effective alternative without compromising on performance.

Electrical Trader’s detailed product listings make it easier for buyers to find equipment tailored to their specific technical and operational needs. The platform also supports specialized applications, such as emergency standby systems, and collaborates with manufacturers and distributors across the United States to ensure timely availability. Delivery times depend on the configuration and manufacturer lead times, so buyers are encouraged to review the product details carefully in each listing.

Conclusion: Key Points on LTCs for Power Transformers

Load tap changers (LTCs) are a cornerstone of modern power distribution systems, playing a pivotal role in maintaining grid reliability and operational efficiency. A clear understanding of their function, coupled with proper maintenance, is essential to ensure uninterrupted power delivery and to avoid costly disruptions.

The Backbone of Voltage Regulation

LTCs are vital for regulating voltage by automatically adjusting transformer output without interrupting the power supply. This functionality improves grid efficiency by cutting power losses, reducing energy waste, and boosting overall system performance. These benefits highlight their importance in ensuring grid stability and supporting cost-effective operations across transmission and distribution networks.

The Importance of Routine Maintenance

Keeping LTCs in peak condition requires consistent maintenance. Neglect can lead to reduced performance, higher operational costs, and unexpected outages. Following manufacturer-recommended maintenance schedules and maintaining thorough records of inspections, testing, and repairs are key steps. Advanced diagnostic tools, such as dissolved gas analysis (DGA) and infrared thermography, are invaluable for detecting issues early, allowing operators to address potential problems before they escalate.

Choosing the Right LTCs

Selecting an LTC that aligns with specific operational and environmental requirements is just as important as maintaining it. A high-quality LTC is critical because a failure can disable an entire transformer, disrupt distribution circuits, and affect the broader power grid.

Steps for Long-Term Success

Ensuring the reliable performance of LTC systems requires a proactive approach. This involves three key practices: employing skilled professionals for maintenance, leveraging advanced diagnostic tools to identify problems early, and keeping detailed records to track performance trends. Whether managing existing systems or planning new installations, focusing on these areas ensures optimal performance and extends the service life of LTCs. By combining effective maintenance, thoughtful equipment selection, and operational expertise, power distribution systems can achieve greater reliability and resilience. Electrical Trader provides the tools and insights needed to support these efforts.

FAQs

What is the difference between On-Load and Off-Load Tap Changers, and how do they affect transformer performance?

The key distinction between On-Load Tap Changers (OLTCs) and Off-Load Tap Changers (NLTCs) lies in how they operate. OLTCs can adjust voltage levels while the transformer is active and carrying a load. This means voltage regulation happens without disrupting the power supply, ensuring a steady flow of electricity. On the other hand, NLTCs require the transformer to be turned off before making any adjustments, which can lead to brief power outages.

OLTCs are a great fit for settings where voltage stability is crucial, especially in systems with fluctuating loads. They keep performance steady even as demand changes. Meanwhile, NLTCs work best in systems with consistent loads or in situations where occasional downtime isn’t a problem. The choice between the two depends on the specific needs of the power system, balancing reliability and efficiency.

How does regular maintenance of Load Tap Changers (LTCs) help prevent failures and extend their lifespan?

Regular upkeep of Load Tap Changers (LTCs) plays a key role in keeping them running smoothly and extending their service life. This involves routine inspections to spot wear or damage, cleaning to eliminate contaminants, and testing to catch potential issues early. Tackling problems at an early stage can prevent expensive failures and unexpected outages.

Timely replacement of worn parts and proper lubrication of moving components are equally important. These practices ensure smoother operation, reduce mechanical strain, and lower the chances of breakdowns. By maintaining LTCs consistently, not only do they operate more efficiently, but they also enhance the overall dependability of power transformers and distribution systems.

What should I consider when choosing the right Load Tap Changer (LTC) for my transformer?

When choosing a Load Tap Changer (LTC) for your transformer, several critical elements come into play. Start by looking at the transformer's MVA rating, voltage, regulating range, and the number of tap positions you'll need. It's also essential to decide on the type of LTC - whether you require an on-load or off-load type - as well as the connection configuration (wye or delta) and the insulation level to ensure it aligns with your system's requirements.

Don't overlook environmental conditions. Factors like operating temperatures and overall working conditions can influence the LTC's reliability and efficiency. By thoroughly evaluating these aspects, you can achieve accurate voltage regulation, enhance system reliability, and get the best performance from your transformer.

Related posts

- Common Transformer Problems and Solutions

- Ultimate Guide to Low Voltage Equipment

- How to Choose an Isolation Transformer

- Pad Mount vs Substation Transformers