How to Choose an Isolation Transformer

Share

Need an isolation transformer but unsure where to start? Here's a quick guide to help you choose the right one for your needs:

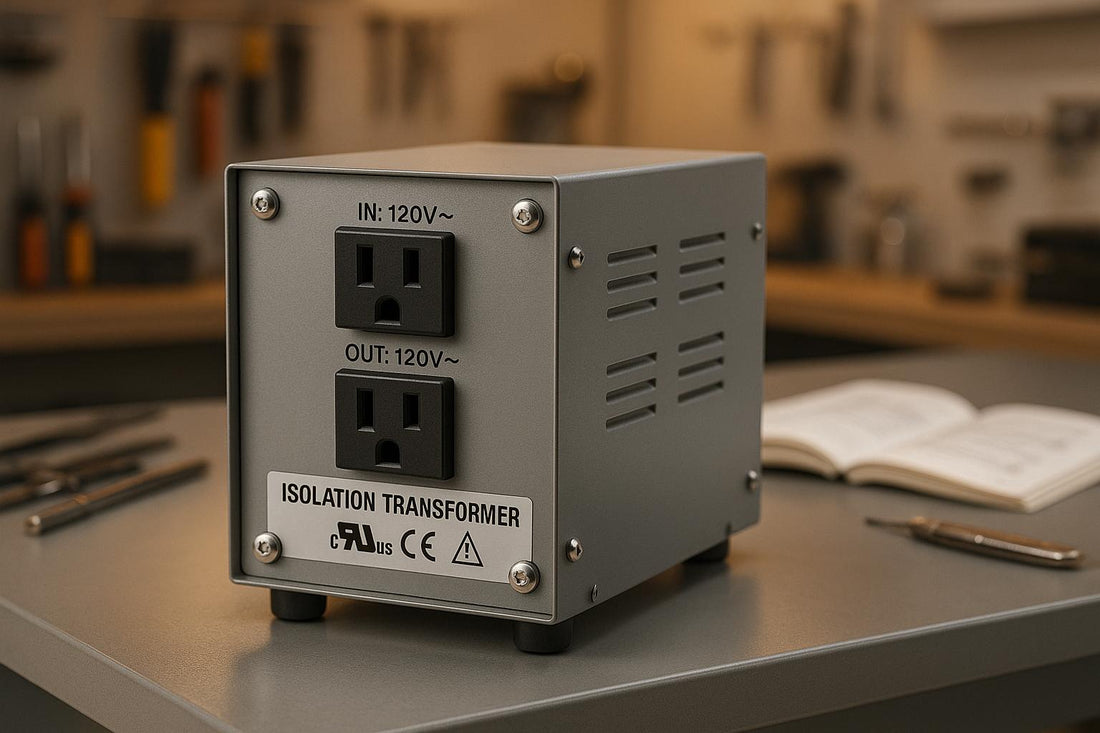

- What It Is: An isolation transformer transfers power between circuits while keeping them electrically separate, blocking disturbances and high-frequency noise.

- Why You Need It: It protects sensitive equipment, ensures safety, and reduces electrical noise and power surges.

-

Key Factors:

- Voltage: Match input/output voltage to your system (e.g., 120V, 240V, 480V).

- Power Rating: Choose a kVA rating 15–20% higher than your total load.

- Safety Standards: Ensure compliance with NEC, OSHA, ANSI, and IEC.

-

Types:

- Ultra Isolation: Best for medical devices and precision equipment.

- Dry Isolation: Durable and low-maintenance for schools and hospitals.

- Drive Isolation: Ideal for motor drives and industrial automation.

Quick Comparison:

| Transformer Type | Best Applications | Key Benefits | Cost Range |

|---|---|---|---|

| Ultra Isolation | Medical, labs, CNC machinery | Maximum noise reduction | High |

| Dry Isolation | Schools, hospitals, manufacturing | Fire-resistant, low maintenance | Moderate |

| Drive Isolation | Motor drives, industrial systems | Harmonics control, thermal protection | High |

Tip: Always calculate your load, consider environmental conditions, and check certifications before purchasing. For a reliable source, look for marketplaces offering new, refurbished, and used options with warranties.

How to Size an Isolation Transformer for a VFD | Galco

Key Selection Criteria for Isolation Transformers

Selecting the right isolation transformer is more than just picking a model off the shelf - it requires a thoughtful assessment of several key factors. These considerations are crucial to ensure the transformer delivers the safety, reliability, and performance you need. Getting it wrong could result in equipment damage, safety risks, or unnecessary costs. Here's what you should keep in mind.

Voltage Requirements

Start by matching the transformer's voltage ratings to your system's needs. In the U.S., most systems operate at 120V, 240V, or 480V. Common isolation transformers are designed to accept input voltages of 208/240/480V at 50/60 Hz and provide output voltages of 120/208/240V. For industrial and commercial use, general-purpose transformers often step down high distribution voltages (like 480V or 600V) to more manageable levels. If you're dealing with specialized low-voltage applications, you can find transformers with input ranges as low as 3.3 to 24 volts. Always double-check wiring diagrams for compatibility and ensure both primary and secondary voltage requirements align with your equipment's specifications.

Power Rating and Load Capacity

The kVA (kilovolt-ampere) rating of a transformer indicates its ability to handle electrical loads safely. Choosing the wrong size can lead to problems - an undersized transformer may overheat or fail, while an oversized one could waste energy and inflate costs. To determine the right size, calculate the total load by multiplying voltage and amperage, then add 25% to account for inrush currents. Aim for a transformer with a kVA rating that's 15–20% higher than your total load. For instance, if your facility uses 75 kVA at peak and you plan to add 25 kVA of equipment, look for a transformer rated at least 125 kVA. It's also important to ensure the actual load stays within 80–100% of the transformer's rated capacity.

Here’s a quick reference for typical transformer sizes and their applications:

| Transformer Size (kVA) | Typical Application |

|---|---|

| 5–15 kVA | Small appliances, household equipment, light industrial use |

| 25–50 kVA | Medium office equipment, small commercial facilities |

| 75–100 kVA | Factory machinery, small to medium factories |

| 150–300 kVA | Large factory equipment, data centers, large buildings |

| 500+ kVA | Extra-large industrial facilities, regional power distribution |

Safety Standards and Code Compliance

Adhering to U.S. safety standards isn't just a best practice - it's a legal and insurance requirement. Compliance with the NEC, NFPA 70E, OSHA regulations, and standards from ANSI, IEEE, and IEC ensures your transformer operates safely and reliably. Keeping up with these standards involves regular monitoring, participating in training sessions and industry events, and conducting routine internal audits. Compliance management tools can also help you stay on track and up to date with changes in regulations.

Types of Isolation Transformers and Their Uses

Isolation transformers are crafted to meet specific needs, ensuring power quality, noise reduction, and equipment safety. Knowing the differences between these types helps you select the right one for your environment and application. Here’s a breakdown of three key types and their uses.

Ultra Isolation Transformers

Ultra isolation transformers are engineered to eliminate both common and transverse mode noise. By using specialized insulating materials and advanced shielding, they achieve dielectric strengths ranging from 1,000V to 4,000V. Additionally, they establish an independent neutral ground on the secondary side, effectively breaking ground loops in sensitive equipment.

These transformers are crucial for protecting critical systems like computers, medical devices (such as MRI machines and life-support systems), digital communication equipment, audio-visual setups, laboratory tools, and CNC machinery. While they come with a higher price tag than standard models, their ability to minimize even the smallest electrical interference makes them indispensable for environments where precision and safety are paramount.

Dry Isolation Transformers

Dry isolation transformers offer a practical solution for a range of settings. Their sealed design shields the core and windings from moisture, dust, and chemicals, making them a reliable choice for schools, hospitals, manufacturing facilities, and clean rooms. They are also fire-resistant and operate in an environmentally safe manner, making them ideal for safety-focused installations.

Unlike oil-filled transformers, dry isolation models require little maintenance and pose no environmental risks if damaged. Their combination of durability, safety, and low upkeep makes them a preferred option for facilities that need dependable power isolation without added complexity.

Drive Isolation Transformers

Drive isolation transformers are specifically built to support both AC and DC variable frequency drives (VFDs). They adjust voltage levels for drives using Silicon Controlled Rectifiers (SCRs) while providing magnetic isolation and reducing wave distortion and eddy-current losses caused by high-frequency return currents. Industrial environments, where electrical noise can create voltage spikes as high as 6,000 volts in three-phase systems, benefit greatly from these transformers.

These transformers are tailored for motor drives and VFDs, addressing issues like harmonic distortion and voltage spikes. Some models even include features like ThermoGuard protection, which alerts operators to overheating, ensuring reliable performance in demanding industrial conditions. Though they are more expensive than general-purpose transformers, their ability to safeguard equipment in high-risk applications makes them essential.

The table below highlights the primary applications, benefits, and typical costs for each transformer type.

| Transformer Type | Best Applications | Key Benefits | Typical Cost Range |

|---|---|---|---|

| Ultra Isolation | Medical equipment, labs, precision instruments | Maximum noise reduction; 1,000V-4,000V dielectric strength | Highest |

| Dry Isolation | Schools, hospitals, manufacturing, clean rooms | Fire-resistant; minimal maintenance; environmental safety | Moderate |

| Drive Isolation | Motor drives, VFDs, industrial automation, HVAC | Harmonic distortion control; thermal protection; spike suppression | High |

sbb-itb-501186b

Isolation Transformer Comparison Chart

Understanding the features of different isolation transformer types can help you choose the right one for your needs. Below is a chart summarizing their primary functions, noise reduction capabilities, resistance to environmental conditions, typical uses, and key benefits. Following the chart, you’ll find a brief explanation of what makes each transformer type stand out.

| Feature | Ultra Isolation | Dry Isolation | Drive Isolation |

|---|---|---|---|

| Primary Function | Eliminates electrical noise | Protects against environmental factors | Powers and isolates motor drives |

| Noise Attenuation | High | Moderate | Moderate (with harmonic management) |

| Environmental Resistance | Low | High | Moderate |

| Typical Applications | Sensitive electronics, medical devices, CNC machinery | Schools, hospitals, chemical industries | AC/DC variable frequency drives and motor control systems |

| Key Benefit | Provides clean and stable power for sensitive equipment | Ensures reliable performance in harsh environments | Optimizes power delivery and protects motor drives |

Ultra isolation transformers are ideal for applications that demand clean, stable power, such as medical devices, CNC machinery, or other sensitive electronics. Their ability to significantly reduce electrical noise makes them perfect for controlled environments requiring top-tier power quality.

Dry isolation transformers, on the other hand, are built to endure rugged conditions. With high resistance to environmental factors, they’re a reliable choice for schools, hospitals, and industries where durability and low maintenance are critical.

Drive isolation transformers are specifically designed for industrial applications involving variable frequency drives and motor control systems. They provide thermal protection and manage harmonics, ensuring efficient power delivery and safeguarding motor drives in demanding settings.

When selecting an isolation transformer, think about what matters most for your application. For instance, if noise reduction is a top priority, ultra isolation transformers are the way to go. If you’re dealing with harsh environments, dry isolation transformers offer the durability you need. And for industrial setups with motor drives, drive isolation transformers deliver the specialized performance required.

Where to Buy Isolation Transformers

When it comes to purchasing an isolation transformer, choosing a trusted marketplace is essential. The right source ensures you get high-quality equipment, fair pricing, and reliable support. Established electrical equipment marketplaces stand out as a smart choice, especially for specialized items like isolation transformers.

Why Choose Electrical Trader?

A reliable marketplace guarantees that the isolation transformers meet the necessary technical and safety standards.

Electrical Trader boasts a wide selection of isolation transformers, including single-phase, three-phase, dry-type, oil-filled, pad-mounted, and substation models. This variety allows you to compare multiple options in one place, eliminating the need to contact several vendors.

Cost flexibility is another major advantage. New medium voltage transformers can cost anywhere from $25,000 to $750,000, depending on their size and type. However, used and reconditioned units are often 30-60% cheaper than new ones. Fully refurbished transformers with warranties are typically priced at 50-70% of new units, while as-is models can cost as little as 20-45% of their original price. This range of options helps you balance your budget with your performance needs.

Simplified procurement is a key benefit of using Electrical Trader. Instead of spending weeks researching vendors, verifying references, and comparing quotes, you can find a variety of transformer options from different sellers on a single platform. This centralized approach saves time and reduces administrative hassle.

Quality assurance is built into the platform through its seller vetting process and detailed product listings. Most transformers include comprehensive technical specifications, so you can confirm voltage ratings, power capacities, and safety certifications before making your decision.

Transformer Options Available

Electrical Trader offers transformer categories suitable for nearly every application. Single-phase transformers are perfect for residential and light commercial use, while three-phase units cater to industrial and heavy commercial demands. Dry-type transformers, which use air for cooling, are ideal for indoor installations where oil-filled models are not suitable.

For high-power applications, oil-filled transformers provide excellent cooling and electrical insulation. These models are known for their efficiency and durability in industrial settings. Pad-mounted transformers are enclosed in protective metal cabinets, making them suitable for ground-level installations in residential and commercial areas. Meanwhile, pole-mounted transformers are commonly used in utility applications.

Each transformer type is designed to meet specific needs and applications. For motor loads, for example, it’s important to ensure that you don’t exceed 60% of the transformer’s maximum capacity to handle starting currents and avoid overheating.

Listings also include certification details for compliance checks. For instance, medical isolation transformers should have UL/IEC 60601-1 certification, while marine units must meet different standards.

Additionally, many sellers provide extra services like on-site support, commissioning, maintenance, and repairs. Warranty options vary, ensuring you can maintain optimal performance throughout the transformer's lifespan.

Conclusion

Selecting the right isolation transformer involves aligning it with your power needs, voltage compatibility, and ensuring it meets safety standards like UL, CE, or IEC certifications.

Different applications demand specific features. For instance, healthcare facilities must adhere to strict isolation standards, industrial settings require durable transformers to support heavy loads, and data centers benefit from units that excel at reducing electrical noise.

Accurate load calculation is equally important. Account for the current demand with a tolerance margin to manage potential spikes. Also, consider factors like operating temperature, humidity, and installation conditions when deciding between dry-type, oil-filled, or sealed transformers.

The quality of construction is another critical factor. A properly chosen transformer not only protects against voltage spikes - sometimes exceeding 6,000V in three-phase systems - but also extends the lifespan of connected equipment and reduces downtime.

Using high-quality core materials and copper windings can significantly cut energy losses. Collaborating with reputable manufacturers and consulting experienced electrical engineers ensures your transformer meets regulatory standards and delivers reliable, long-term performance.

FAQs

What should I consider to ensure my isolation transformer meets safety standards?

When choosing an isolation transformer, ensuring it complies with safety standards is crucial to safeguard both users and equipment. Start by identifying the specific standards applicable to your use case. For instance, UL 60601 applies to medical devices, while UL 1585 covers general-purpose transformers. These standards define key safety and performance requirements.

Check that the transformer provides effective electrical isolation to reduce the risk of electric shock and maintains low leakage current to stay within safety limits. It's also important to confirm that the transformer’s dielectric strength - its capacity to withstand high voltage - meets the demands of your application. Lastly, prioritize products that have undergone testing and certification by recognized safety organizations to ensure they comply with all necessary regulations.

How do I choose the right kVA rating for an isolation transformer to meet my electrical load requirements?

To choose the right kVA rating for an isolation transformer, start by calculating the electrical load of your facility. Here's how:

- For single-phase transformers: Use the formula kVA = (Voltage (V) × Current (I)) ÷ 1,000.

- For three-phase transformers: Apply the formula kVA = (Voltage (V) × Current (I) × 1.732) ÷ 1,000.

Once you've calculated the kVA, round up to the nearest standard transformer size to ensure it meets your needs. To keep the transformer running efficiently and prevent overheating, it's a good idea to limit usage to no more than 80% of its kVA capacity. If you're uncertain or need guidance, reaching out to a professional can help ensure you select the right transformer for your application.

What are the key advantages of using an ultra isolation transformer for sensitive equipment?

Ultra isolation transformers bring several benefits when it comes to protecting sensitive equipment:

- Enhanced Electrical Isolation: They create a strong barrier between the power source and connected devices, lowering the chances of electrical faults, surges, or shocks.

- Reduced Electrical Noise: By cutting down on interference, these transformers ensure stable performance for delicate electronics, which is especially important in environments like hospitals or laboratories.

- Protection Against Surges: They shield equipment from voltage spikes, acting as a defense against power disturbances.

These qualities make ultra isolation transformers a dependable choice for critical settings like healthcare facilities, data centers, and other environments where equipment stability is a top priority.

Related posts

- Common Transformer Problems and Solutions

- Ultimate Guide to Low Voltage Equipment

- Electrical Safety Questions Every Pro Should Know

- Voltage Regulation Problems: Causes and Fixes