Explosion-Proof vs Intrinsically Safe: Key Differences

Share

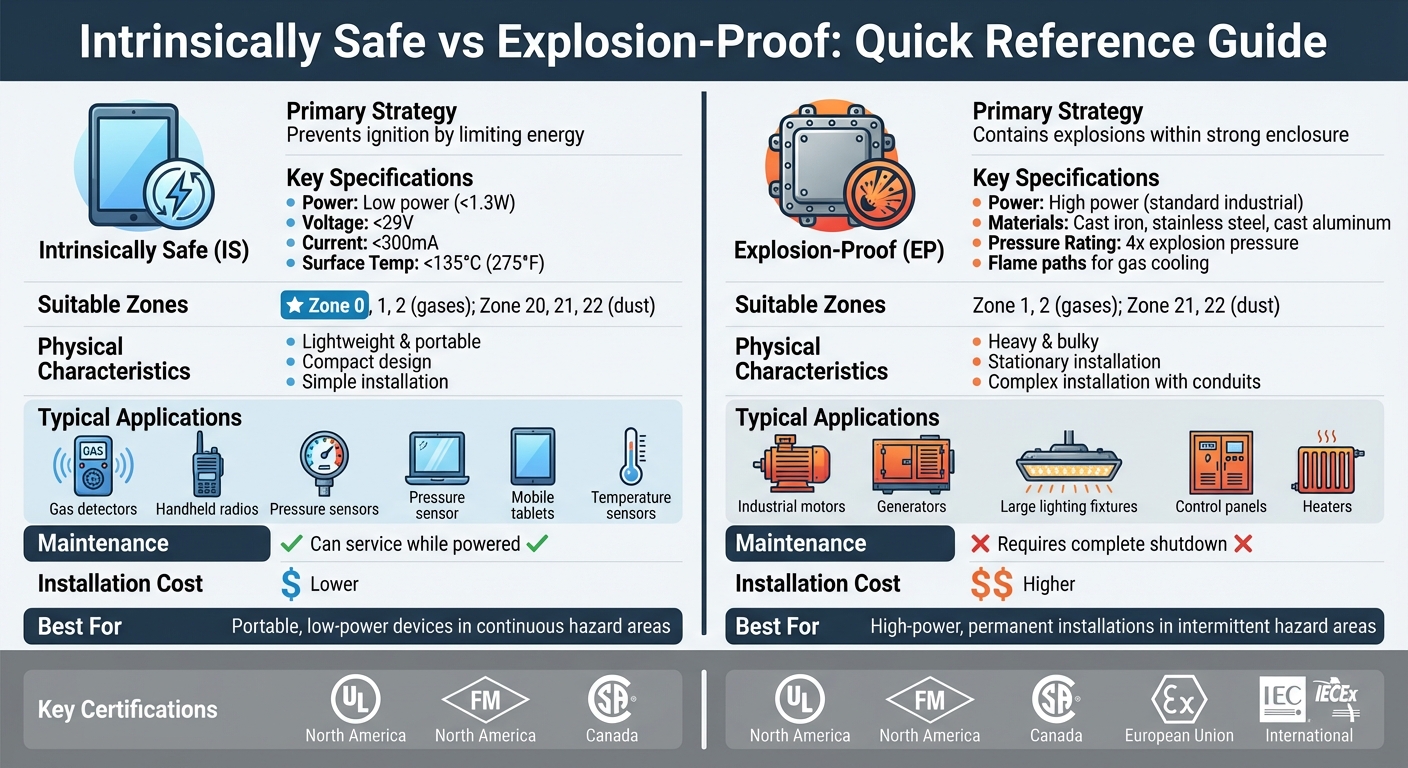

Choosing the right safety equipment for hazardous environments can prevent accidents and save lives. Here's the difference:

- Intrinsically Safe (IS): Limits energy output to prevent sparks or heat that could ignite flammable materials. Ideal for portable, low-power devices like gas detectors and sensors. Suitable for Zone 0, where explosive substances are present continuously.

- Explosion-Proof (EP): Contains internal explosions to prevent them from spreading. Built for high-power, stationary systems like motors and lighting. Suitable for Zone 1 and Zone 2, where hazards are intermittent.

Key Points:

- IS equipment is lightweight, easier to install, and allows maintenance without shutting down operations.

- EP equipment is heavy-duty, more expensive, and requires full shutdowns for maintenance.

Quick Comparison

| Feature | Intrinsically Safe (IS) | Explosion-Proof (EP) |

|---|---|---|

| Primary Strategy | Prevents ignition | Contains explosion |

| Power Capacity | Low power (<1.3W) | High power |

| Zones Supported | Zone 0, 1, 2 | Zone 1, 2 |

| Portability | Lightweight, portable | Heavy, stationary |

| Maintenance | Can service while powered | Requires shutdown |

| Installation Cost | Lower | Higher |

For hazardous areas, IS suits low-power, portable devices, while EP handles high-power, permanent setups. Always check certifications like UL, ATEX, or IECEx to ensure compliance.

Intrinsically Safe vs Explosion-Proof Equipment Comparison Chart

Intrinsically Safe Equipment vs. Explosion-Proof Enclosures

What Is Intrinsically Safe Equipment?

Intrinsically safe (IS) equipment is designed to prevent ignition in hazardous environments by limiting energy output rather than containing potential explosions. The fundamental idea is straightforward: these devices restrict electrical and thermal energy to levels so low that even in the event of faults - like short circuits or damaged wires - no spark or heat is produced that could ignite flammable gases, vapors, or dust.

IS equipment operates within strict energy parameters, typically below 29 volts, 300 milliamps, and 1.3 watts. Additionally, their surface temperatures are carefully controlled to stay below the auto-ignition point of hazardous substances. For instance, T4-rated equipment ensures surface temperatures remain under 135°C (275°F). Even seemingly small energy levels, like a 30-volt, 150-milliamp circuit, can generate a spark powerful enough to ignite hydrogen.

To achieve this level of safety, IS systems rely on safety barriers. These barriers, which include Zener diodes, resistors, and fuses, limit the voltage and current entering hazardous zones. All components - wiring, barriers, and devices - must be certified together as a complete intrinsically safe loop. By combining strict power limits with these safety barriers, IS equipment ensures protection even during equipment failures.

This makes IS equipment ideal for low-power applications such as sensors, pressure transmitters, handheld radios, gas detectors, thermocouples, and portable instruments. In fact, IS is the only method of protection allowed in Zone 0 environments, where flammable gases or vapors are present continuously. Another advantage is that technicians can often perform maintenance on live IS equipment without shutting down operations or obtaining gas clearance certificates.

"The intrinsically safe rating means that the electronics or wiring contained within the equipment cannot spark or accumulate enough energy to ignite the gas or vapor at the location."

– Preston Marcoux, Mechanical Engineer, Linc Energy Systems

These features make IS equipment a critical choice for ensuring safety in hazardous environments.

What Is Explosion-Proof Equipment?

Explosion-proof (EP) equipment takes a different safety approach compared to intrinsically safe designs. Instead of completely avoiding ignition, EP equipment is built to contain an internal explosion, stopping it from spreading. According to the National Electrical Code, it’s defined as being "enclosed in a case that can withstand an explosion of a specified gas or vapor that may occur within it".

This containment is achieved using tough materials like cast aluminum, stainless steel, or cast iron. These materials give the equipment the strength it needs to handle and confine internal explosions.

A key part of the design is the use of flame paths. These are specially crafted joints and threaded connections that let high-pressure gases escape while cooling them below the ignition temperature. Additionally, the design ensures that the external surface of the enclosure stays below the auto-ignition temperature of the surrounding gases or vapors.

"The containment school of thought allows the ignition to happen, but keeps it from spreading to open atmosphere where it becomes dangerous." – Kevin Findlay, Engineer

Because of these features, EP equipment works well in high-power settings like motors, generators, large lighting fixtures, transformers, and electrical junction boxes. Unlike intrinsically safe equipment, which is typically limited to low-power circuits under 1.3 watts, explosion-proof systems can handle high voltage and wattage demands. However, this capability comes with some drawbacks: EP enclosures are heavier, bulkier, and more expensive to install.

Design Principles: Intrinsically Safe vs. Explosion-Proof

When it comes to handling hazardous environments, two key design approaches stand out: intrinsically safe and explosion-proof. Both aim to prevent disasters, but they tackle the problem in entirely different ways.

Intrinsically safe equipment works by ensuring that ignition simply can't happen. It does this by limiting the electrical and thermal energy to levels below the Minimum Ignition Energy (MIE) required to ignite a hazardous material. On the other hand, explosion-proof equipment takes a more structural approach. It assumes an explosion might occur internally but focuses on containing it within a durable enclosure.

"Intrinsically safe refers to explosion prevention, whereas explosion-proof refers to containment." – Pruftechnik

How Intrinsically Safe Equipment Works

The core idea behind intrinsically safe designs is energy limitation. Components like Zener diodes and fail-open resistors are used to cap voltage and restrict current flow. These systems operate at very low power - typically less than 1.3 watts - to ensure surface temperatures remain safe. Additionally, circuit boards are carefully designed to avoid using large capacitors or inductors, which could store and release enough energy to create a spark.

How Explosion-Proof Equipment Works

Explosion-proof systems, by contrast, rely on physical strength and engineering. The equipment is housed in enclosures made from robust materials like cast iron, stainless steel, or cast aluminum - strong enough to withstand the pressure of an internal explosion. In North America, these enclosures are rigorously tested to withstand up to four times the pressure of a gas explosion. A key feature of these systems is the use of engineered flame paths, which allow hot gases to escape safely after being cooled below the ignition point.

Comparison Table: Design Principles

| Feature | Intrinsically Safe (IS) | Explosion-Proof (EP) |

|---|---|---|

| Primary Strategy | Prevents ignition by limiting energy | Contains explosions within a strong enclosure |

| Energy Management | Limits voltage, current, and heat | Handles internal pressure and cools escaping gases |

| Power Capacity | Low power (typically <1.3W) | High power (e.g., motors, heaters, lights) |

| Typical Materials | Lightweight plastics, non-ferrous metals | Cast iron, stainless steel, cast aluminum |

| Thermal Control | Keeps surface temperatures under 275°F (135°C) | Ensures external surfaces stay below ignition thresholds |

| Hazardous Zones | Suitable for Zones 0, 1, and 2 | Suitable for Zones 1 and 2 only |

Both approaches have their strengths and are used in different scenarios depending on the specific risks and requirements of the environment. While intrinsically safe systems focus on preventing ignition altogether, explosion-proof designs prioritize containing any potential incident to keep the surroundings safe.

Installation and Maintenance Differences

When it comes to everyday use, intrinsically safe and explosion-proof equipment require very different handling. These differences affect how they are installed, the complexity of maintenance, and the expertise needed to manage them. Let’s break down the key points for each approach.

Intrinsically safe equipment is designed to be lightweight and compact, eliminating the need for heavy lifting or reinforced mounts. Installation is straightforward, as it only requires an IS barrier, bypassing the need for the heavy-duty conduits used in explosion-proof systems. A major perk is that IS equipment can often be serviced without shutting down power, which helps avoid production interruptions.

"Intrinsically safe devices are often lighter weight and less bulky than explosion-proof devices. They can also be more easily maintained without shutting down production." – Pruftechnik

Explosion-proof equipment, on the other hand, comes with more challenges. It involves heavy, bulky enclosures that demand complex installation processes, including rigid conduits and specialized seals. Any fault in the system requires a full power shutdown before maintenance can begin. Maintenance itself is more intricate, as it involves inspecting flame paths, threaded joints, and seals to ensure safety standards are met.

Comparison Table: Installation and Maintenance

| Feature | Intrinsically Safe (IS) | Explosion-Proof (XP) |

|---|---|---|

| Physical Characteristics | Lightweight and compact | Heavy, bulky enclosures |

| Installation Complexity | Simple; requires IS barriers | Complex; requires conduits and seals |

| Wiring Requirements | Standard wiring with IS barriers | Heavy-duty conduits required |

| Maintenance Method | Can be serviced while powered | Requires complete power shutdown |

| Servicing Tools | Standard tools | Often needs specialized tools |

| Downtime During Repairs | Minimal; no shutdown needed | Significant; full shutdown required |

| Key Inspection Areas | Circuit integrity, barrier function | Flame paths, seals, threaded joints |

| Installation Cost | Typically lower | Typically higher |

The decision between these systems often hinges on operational needs. For setups where minimizing downtime is crucial - like low-power devices such as sensors or handheld tools - intrinsically safe equipment is a clear winner. On the flip side, for high-power, stationary machinery like industrial heaters or large motors, explosion-proof systems are often the only viable option due to their ability to handle higher energy levels safely.

sbb-itb-501186b

Applications and Use Cases

When deciding between Intrinsically Safe (IS) and Explosion-Proof (XP) equipment, the choice often comes down to power needs and the level of hazard in the environment. Knowing where each type excels can guide you toward the right solution for your facility.

Intrinsically safe equipment is the go-to for portable, low-power devices. These include gas detectors, handheld radios, pressure sensors, and mobile tablets - devices that typically operate under 1.3W. Such equipment plays a vital role in industries like oil and gas (e.g., offshore platforms), mining, pharmaceuticals, chemical plants, and food manufacturing, where the risk of explosions, such as from grain dust, is high. Its ability to function in Zone 0 and Zone 20 - areas with constant explosive hazards - makes it indispensable. If your team needs to carry tools into highly dangerous zones, IS equipment is the only safe option.

Explosion-proof equipment, on the other hand, is designed for high-power, stationary systems like motors, generators, large lighting fixtures, and control panels. It’s widely used in industries such as oil refineries, heavy manufacturing, and grain handling facilities. These environments depend on XP enclosures to safely operate machinery that demands more power than IS devices can handle. For example, Marathon produces explosion-proof motors built with solid cast iron to meet Class I, Division 1 standards and Temperature Code T3C requirements. These motors are critical in refinery operations where reliability is non-negotiable.

Real-world examples emphasize the importance of matching equipment to specific hazards. In South Africa's mining sector, stricter safety protocols - including the adoption of hazardous area equipment and advanced vehicle intervention systems - led to an 80% drop in fatalities between 2003 and 2022. This progress highlights how proper equipment choices can directly improve worker safety.

Here’s a quick comparison of typical applications for IS and XP equipment:

Comparison Table: Applications and Use Cases

| Feature | Intrinsically Safe (IS) | Explosion-Proof (XP) |

|---|---|---|

| Typical Equipment | Gas detectors, handheld radios, sensors, tablets | Motors, generators, lighting fixtures, control panels |

| Power Level | Low power (typically <1.3W) | High power (standard industrial levels) |

| Portability | Lightweight, portable devices | Heavy, stationary installations |

| Suitable Zones | Zone 0, 1, 2 (gases); Zone 20, 21, 22 (dust) | Zone 1, 2 (gases); Zone 21, 22 (dust) |

| Oil & Gas Applications | Two-way radios, lapel mics, pressure sensors | Heavy-duty motors, control panels, refinery lighting |

| Mining Applications | Portable monitoring equipment, collision avoidance sensors | Large ventilation fans, junction boxes, stationary machinery |

| Food Processing | Grain dust monitors, handheld communication tools | Bucket elevator motors, conveyor belt systems |

| Chemical/Pharma | Temperature sensors, laboratory instruments, tablets | Mixing motors, high-wattage heaters, large-scale lighting |

| Installation Type | Mobile or fixed | Permanent/Stationary only |

| Primary Industries | Mining, pharmaceuticals, oil & gas exploration | Refineries, heavy manufacturing, grain handling |

This breakdown makes it easier to see which type of equipment aligns with your operational needs and safety requirements.

Standards and Certifications

When choosing equipment for hazardous environments, certifications play a critical role in ensuring that devices won’t ignite flammable materials. In the United States, the National Electrical Code (NEC) - published by the National Fire Protection Association (NFPA) - provides the primary guidelines for electrical equipment in hazardous locations. Updated every three years, the NEC incorporates new safety research and industry advancements to keep standards current. These guidelines serve as the foundation for all certification processes.

In North America, organizations like Underwriters Laboratories (UL), Factory Mutual (FM), and the Canadian Standards Association (CSA) are responsible for certifying equipment. Their job is to ensure that devices meet rigorous safety standards. For instance, UL certification requires third-party testing by a Nationally Recognized Testing Laboratory (NRTL) to confirm compliance with specific standards, such as UL 913 for intrinsically safe devices or UL 1203 for explosion-proof equipment.

For international applications, ATEX and IECEx certifications are often key considerations. While not U.S. standards, they are widely recognized when sourcing equipment globally. ATEX is a European Union directive for equipment used in explosive atmospheres, requiring products to display the CE mark alongside an "Ex" hexagon symbol. On the other hand, IECEx provides a voluntary international certification system aimed at harmonizing global standards and reducing redundant testing by issuing a certificate recognized in multiple countries.

In addition to international certifications, U.S. standards offer a detailed classification system for hazardous environments. Traditionally, these environments are categorized using the Class and Division system:

- Class I: Flammable gases and vapors

- Class II: Combustible dust

- Class III: Ignitable fibers

Within each class, Division 1 indicates hazards that are present continuously, while Division 2 applies to abnormal conditions. However, North America is increasingly adopting the European-style Zone system (NEC 505/506) to align more closely with global practices. Furthermore, equipment is assigned a temperature classification ranging from T1 (450°C) to T6 (85°C), ensuring surface temperatures remain below ignition points.

The importance of proper certification cannot be overstated. Even a small spark in a hazardous area can lead to catastrophic consequences. For example, in December 2025, Fluke Reliability reported that two industrial customers using VibGuard IIoT condition monitoring systems - certified for hazardous environments - prevented over $1.7 million in potential damages and unplanned downtime by identifying equipment issues early. Always check for the "Ex" symbol or UL/FM markings and consult hazardous area engineers for site-specific requirements. The right certification not only ensures operational safety but also enhances equipment reliability and performance.

Selecting the Right Equipment on Electrical Trader

When browsing Electrical Trader's marketplace, the first step is to evaluate the specific hazardous environment where the equipment will be used. For Zone 0 environments, only intrinsically safe equipment is suitable. In Zone 1 and Zone 2 areas, you can choose between intrinsically safe and explosion-proof options, depending on power needs and whether the equipment needs to be portable. This environmental assessment is crucial as it directly impacts the power requirements of the tools you select.

The equipment's design and power levels also play a role in your decision. Low-power devices - such as gas detectors, handheld radios, pressure sensors, and mobile tablets - typically require intrinsically safe equipment. These products operate at approximately 1.2V, 0.1A, 20 microjoules, and 25mW. On the other hand, high-power equipment like industrial motors, LED lighting fixtures, fans, or heaters demands explosion-proof enclosures. These enclosures are built to handle higher energy levels while containing any potential internal failures.

Always check for certification markings like UL, FM, ATEX, or IECEx in product descriptions to ensure compliance with safety standards.

"Explosion-proof is the more commonly used method for detector/sensor assemblies for fixed gas detection systems. It's designed for permanent installations that require higher voltage/power." – Michael Douglas, National Manager at Levitt-Safety

Before making a purchase, confirm that the equipment aligns with your site's hazard classifications.

Beyond technical compatibility, it's important to weigh both upfront costs and long-term expenses. Intrinsically safe systems generally have a lower initial cost and can reduce downtime since they often allow for maintenance without halting operations. Explosion-proof equipment, while more expensive initially due to its robust materials, may be more cost-effective for permanent, high-power setups. Consulting hazardous area engineers can help ensure that the equipment specifications meet your facility's unique requirements.

Comparison Table: Pricing and Features

| Equipment Category | Protection Type | Typical Price Range | Key Features | Best For |

|---|---|---|---|---|

| Portable Gas Detectors | Intrinsically Safe | Lower initial cost | Lightweight, battery-operated, Zone 0 rated, live maintenance | Chemical plants, refineries |

| Industrial Motors | Explosion-Proof | Higher initial cost | Heavy-duty cast housing, high-power support, durable | Offshore rigs, manufacturing |

| Handheld Radios | Intrinsically Safe | Lower initial cost | Prevents static/sparking, compact, easy to carry | Communication in hazardous areas |

| LED Lighting Fixtures | Explosion-Proof | Higher initial cost | Heat-resistant, contains internal failures, permanent mount | Petrochemical facilities |

| Process Sensors | Intrinsically Safe | Lower initial cost | Low-power signals, simple wiring, live calibration | Oil refineries, distilleries |

| Ventilation Fans | Explosion-Proof | Higher initial cost | High-voltage capable, robust enclosure, sealed conduits | Gas-saturated environments |

Conclusion

Deciding between intrinsically safe (IS) and explosion-proof (EP) equipment comes down to the specific needs of your facility. Intrinsically safe equipment works by limiting electrical energy - usually below 1.3W - to prevent ignition. This makes it perfect for portable devices like gas detectors, radios, and sensors. It's also the only choice for Zone 0 areas, where explosive atmospheres are present continuously. On the other hand, explosion-proof equipment is designed to contain internal explosions within durable enclosures, making it suitable for high-power applications like industrial motors, large lighting systems, and heaters in Zone 1 and Zone 2 environments.

IS equipment tends to have lower upfront costs and allows for on-line maintenance, making it an attractive option for certain setups. Meanwhile, EP equipment is built for high-power, permanent installations and requires a greater initial investment due to its rugged design. Understanding these differences underscores the importance of aligning equipment with your facility's hazard classification.

In hazardous settings, attention to detail is essential to ensure safety and operational efficiency. When exploring options on Electrical Trader's marketplace, double-check that certifications align with your site's specific requirements. Consulting with qualified hazardous area engineers can also help you make the right choice. Whether you're looking for lightweight, portable sensors or robust enclosures for heavy-duty machinery, selecting properly certified equipment is crucial for safeguarding both your team and your operations.

FAQs

What is the difference between intrinsically safe and explosion-proof equipment?

The main distinction between these two types of equipment lies in how they prevent explosions in hazardous settings. Intrinsically safe equipment operates by restricting electrical and thermal energy, which prevents sparks or overheating. This makes it ideal for environments with the highest risk levels (Zones 0-2). It's also lightweight, easier to handle, and, in some cases, can even be maintained without cutting off the power.

In contrast, explosion-proof equipment relies on sturdy, sealed enclosures designed to contain any internal explosion, stopping it from igniting the surrounding atmosphere. This type of equipment is usually heavier, intended for slightly lower-risk areas (Zones 1-2), and often requires power to be shut down for maintenance. Both play a critical role in industries like oil and gas, mining, and chemical processing, with their use determined by the specific dangers and demands of the environment.

What hazardous areas are suitable for intrinsically safe equipment?

Intrinsically safe equipment is crafted for environments where the risk of explosions is high due to flammable gases, vapors, or dust. These hazardous areas are categorized into zones or divisions, depending on the frequency and duration of exposure to these substances. Internationally, classifications include Zone 0, Zone 1, and Zone 2, while the U.S. system uses Division 1 and Division 2.

For instance, Zone 0 or Division 1 areas demand intrinsically safe equipment because explosive atmospheres are either constantly or frequently present. It's crucial to match the equipment's certification with the specific classification of the area to ensure it meets all safety standards.

What role do UL and ATEX certifications play in ensuring equipment safety in hazardous environments?

UL (Underwriters Laboratories) and ATEX (ATmosphères EXplosibles) certifications play a crucial role in ensuring equipment can safely operate in hazardous environments. These certifications confirm that the equipment won’t ignite flammable gases, vapors, or dust, making them essential for safety. UL certification is tailored to North American standards, examining factors like temperature, electrical energy, and spark-proofing before granting the UL-listed mark. On the other hand, ATEX certification, mandatory in the European Union, involves a comprehensive design review and approval process to certify equipment for specific zones, gas groups, and temperature classes.

By meeting these standards, companies can lower the risk of accidental ignition, safeguard workers, and comply with regulations such as the U.S. National Electrical Code (NEC). For U.S. businesses, Electrical Trader provides a broad range of UL-listed and ATEX-certified components, simplifying the process of sourcing reliable and regulation-compliant equipment for industries like oil and gas, chemical processing, and mining.